Cooling type die-casting machine charging barrel assembly

A die-casting machine and cooling technology, applied in the field of cooling die-casting machine barrel components, can solve the problems of short service life of the barrel and the hammer head, poor cooling effect, increased cost, etc., to improve the heat dissipation effect, improve the cooling speed, The effect of accelerating the rate of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

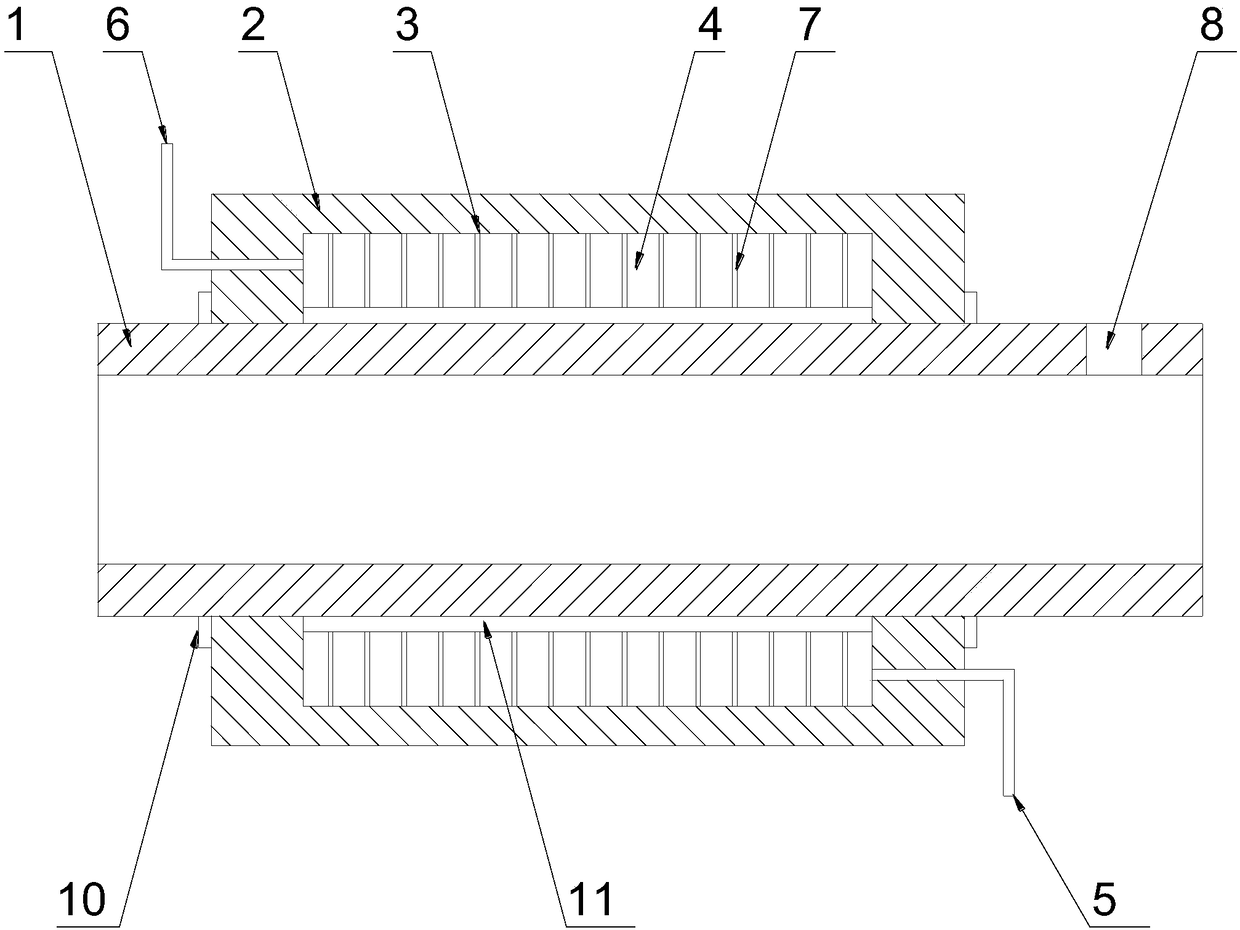

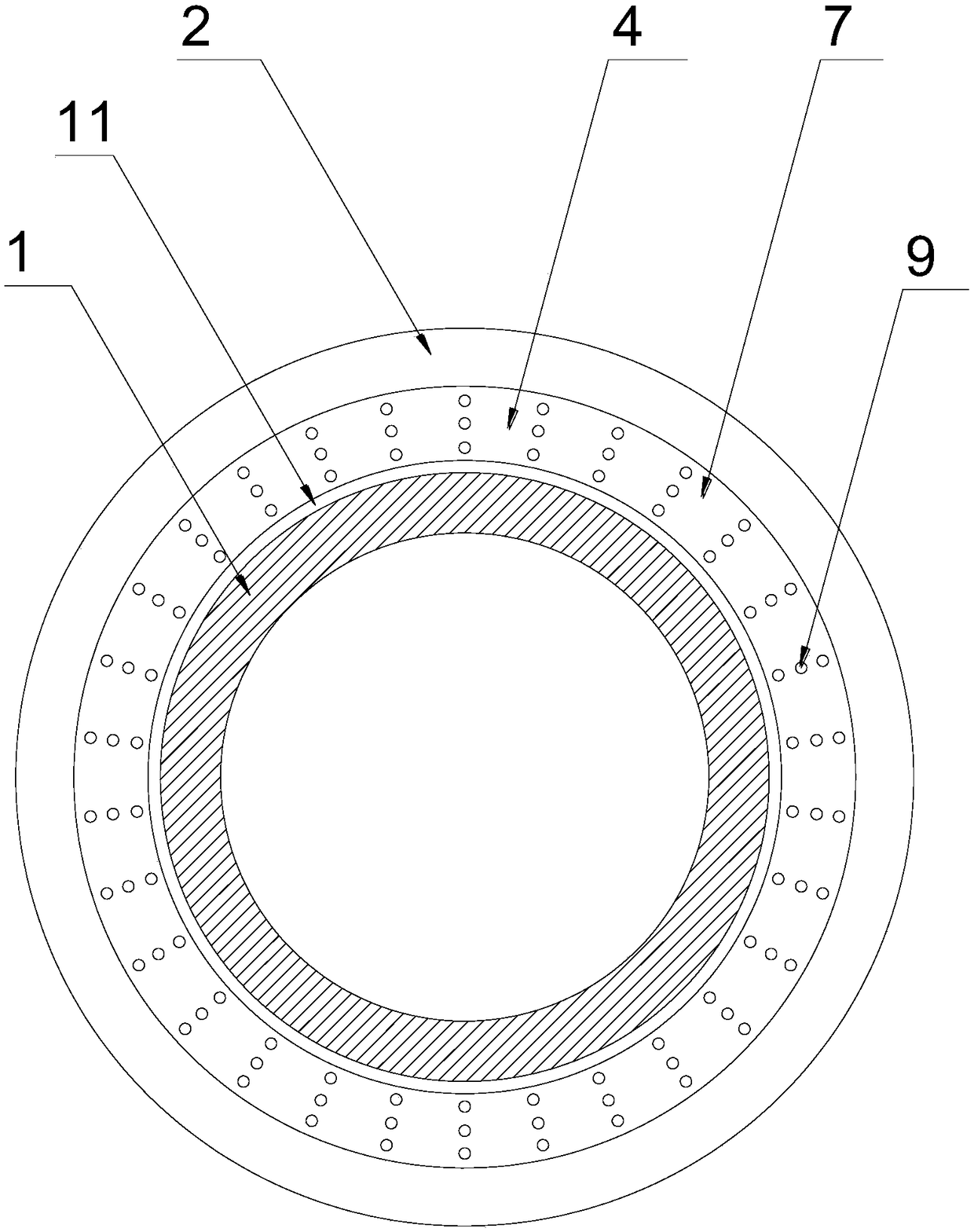

[0024] Such as Figure 1-2 as shown, figure 1 It is a structural schematic diagram of a barrel assembly of a cooling die-casting machine proposed by the present invention.

[0025] figure 2 It is a partial structural cross-sectional view of the cylinder assembly of the cooling die-casting machine proposed by the present invention.

[0026] refer to Figure 1-2 , a cooling type die-casting machine barrel assembly proposed by the present invention, including a barrel 1, a sleeve 2, a cooling element 4, a heat dissipation plate 7, a water inlet pipe 5 and a water outlet pipe 6;

[0027] One end of the barrel 1 is provided with a blanking opening 8;

[0028] The sleeve 2 is sleeved on the outer periphery of the barrel 1; the middle part of the sleeve 2 is provided with a storage bin 3 with an opening facing the outer periphery of the barrel 1;

[0029] The cooling element 4 is arranged in a cylindrical shape and the inside is hollow to form a water tank; the cooling element ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com