Preparation method of lightweight and high-strength high-energy glue-rigid foam composite material structure

A technology of rigid foam and high-energy glue, which is applied in the field of fiber composite molding, can solve the problems of high production cost, affecting the interlayer bonding force of products, and low interlayer bonding force, and achieve the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

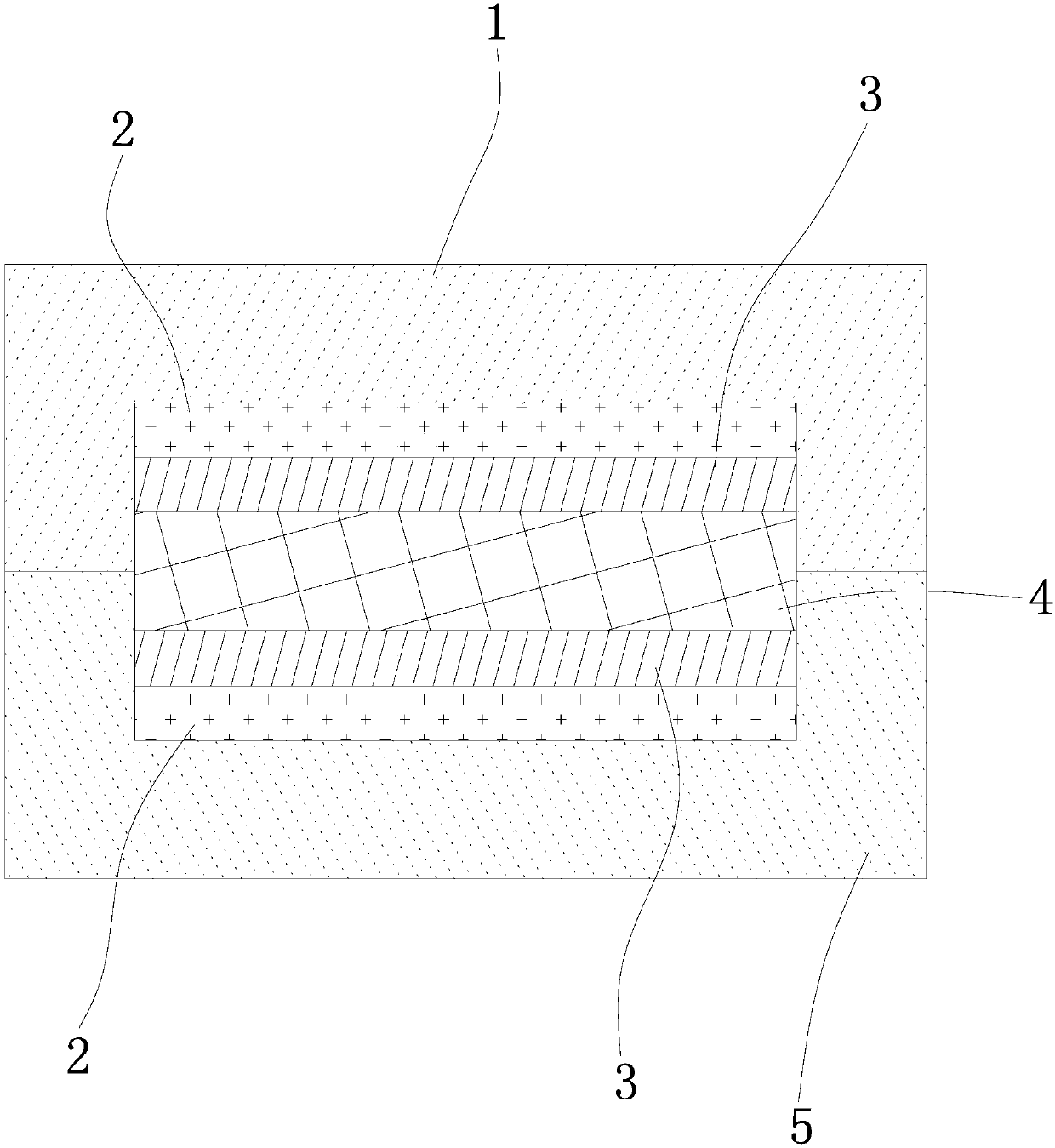

Image

Examples

Embodiment 1

[0024] Example 1: Preparation of a lightweight, high-strength, high-energy glue-rigid foam composite structure:

[0025] Cutting: cutting high-energy glue, fiber prepreg and rigid foam;

[0026] Roll preform: Wrap rigid foam with high-energy glue, and then wrap fiber prepreg on the outside of high-energy glue;

[0027] Mold molding: Put the preformed product into the mold, close the mold and cover it tightly, heat the mold at 100°C for 60 minutes, the high-energy glue in the product is heated to generate expansion force from the inside to the outside, and the fiber prepreg is cured at high temperature forming;

[0028] Cooling and demoulding: Cool the formed mold to a temperature of 20-80°C, open the mold and take out the composite structure of high-energy glue-rigid foam;

[0029] The maximum expansion strength of the high-energy glue during thermal expansion is less than or equal to the compressive strength of the hard foam at 10% compression deformation, that is, the defo...

Embodiment 2

[0031] Example 2: Preparation of a lightweight, high-strength, high-energy adhesive-rigid foam composite structure

[0032] Cutting: cutting high-energy glue, fiber prepreg and rigid foam;

[0033] Roll preform: Wrap rigid foam with high-energy glue, and then wrap fiber prepreg on the outside of high-energy glue;

[0034] Mold molding: Put the preformed product into the mold, close the mold and cover it tightly, heat the mold at 200°C for 10 minutes, the high-energy glue in the product is heated to generate expansion force from the inside to the outside, and the fiber prepreg is cured at high temperature forming;

[0035] Cooling and demoulding: Cool the formed mold to a temperature of 20-80°C, open the mold and take out the composite structure of high-energy glue-rigid foam;

[0036] The maximum expansion strength of the high-energy glue during thermal expansion is less than or equal to the compressive strength of the hard foam at 10% compression deformation, that is, the d...

Embodiment 3

[0038] Example 3: Preparation of lightweight, high-strength, high-energy adhesive-rigid foam composite structure

[0039] Preparation of lightweight, high-strength, high-energy adhesive-rigid foam composite structure:

[0040] Cutting: cutting high-energy adhesive HR-313, fiber prepreg and rigid foam;

[0041] Roll preform: Wrap rigid foam with high-energy glue, and then wrap fiber prepreg on the outside of high-energy glue;

[0042] Mold molding: Put the preformed product into the mold, close the mold and cover tightly, heat the mold at 120°C for 40 minutes, the high-energy glue in the product will expand from the inside to the outside when heated, and the fiber prepreg will be cured at high temperature forming;

[0043] Cooling and demoulding: Cool the formed mold to a temperature of 20-80°C, open the mold and take out the composite structure of high-energy glue-rigid foam;

[0044] The maximum expansion strength of the high-energy glue during thermal expansion is less th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com