Transmission system of gearbox of hybrid electric vehicle

A hybrid electric vehicle and transmission system technology, which is applied to the layout of multiple different prime movers of hybrid electric vehicles and general power plants, motor vehicles, etc., can solve the problems of not being able to drive all gears, complex structure of the transmission system, and high cost , to achieve the effect of being conducive to the loading of the whole vehicle, compact transmission system and good power performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

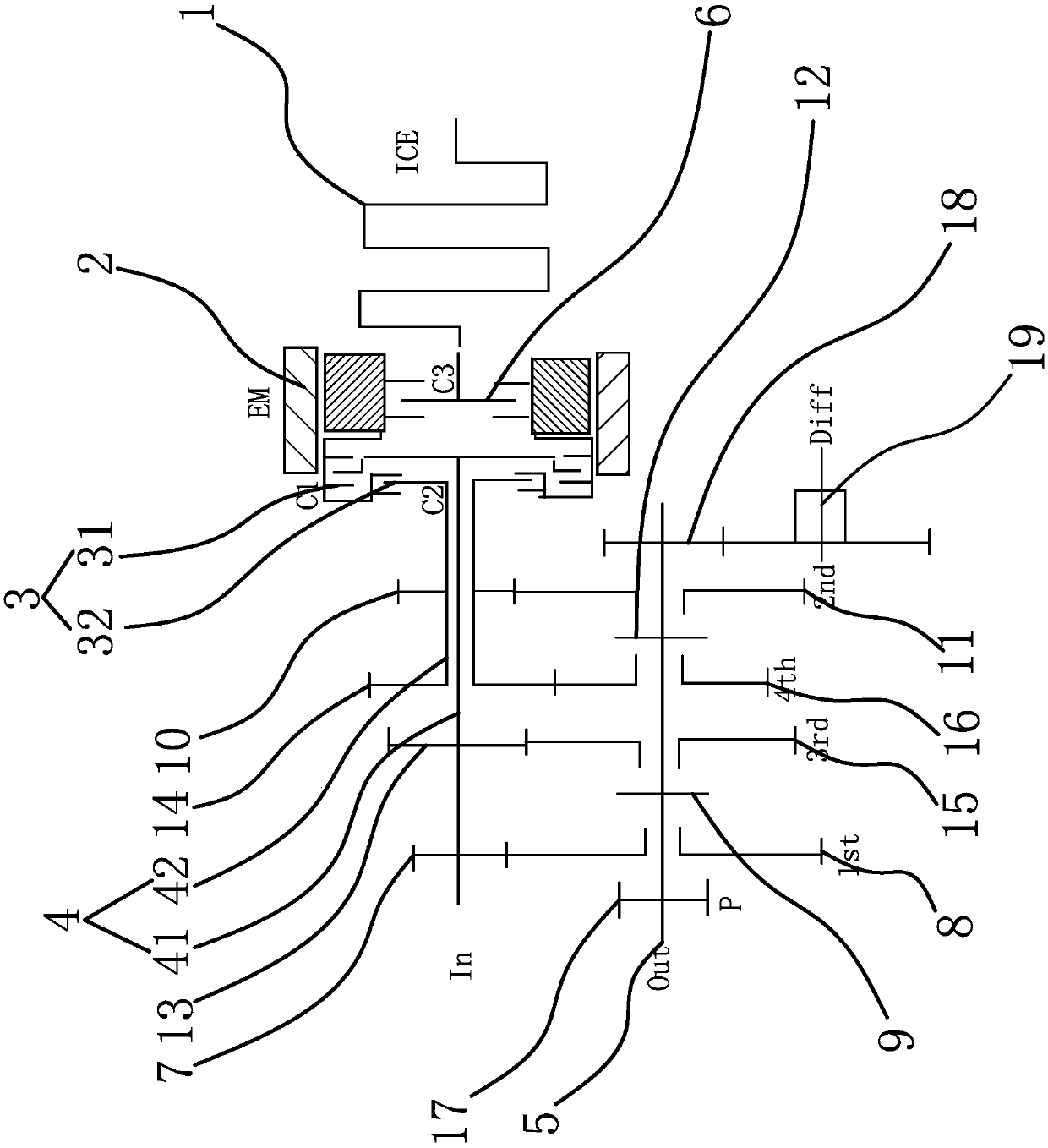

[0022] Specifically, as figure 1 As shown, the transmission system of the hybrid vehicle transmission includes an engine 1, an electric motor 2, a coupling clutch 3, an input shaft 4 and an output shaft 5, and there are two input shafts 4, which are respectively the first input shaft 41 and the second input shaft 42, The second input shaft 42 is sheathed on the first input shaft 41 and is rotatably connected with the first input shaft 41 . There are two coupling clutches 3, namely a first clutch 31 and a second clutch 32. The output shaft 5 is connected to the first input shaft 41 and the second input shaft 42 through the gear gear structure corresponding to the gear position of the vehicle. The motor 2 is in drive connection with the first input shaft 41 through the first clutch 31 , and the motor 2 is in drive connection with the second input shaft 42 through the second clutch 32 . The engine 1 is in transmission connection with the electric motor 2 through the interlockin...

Embodiment 2

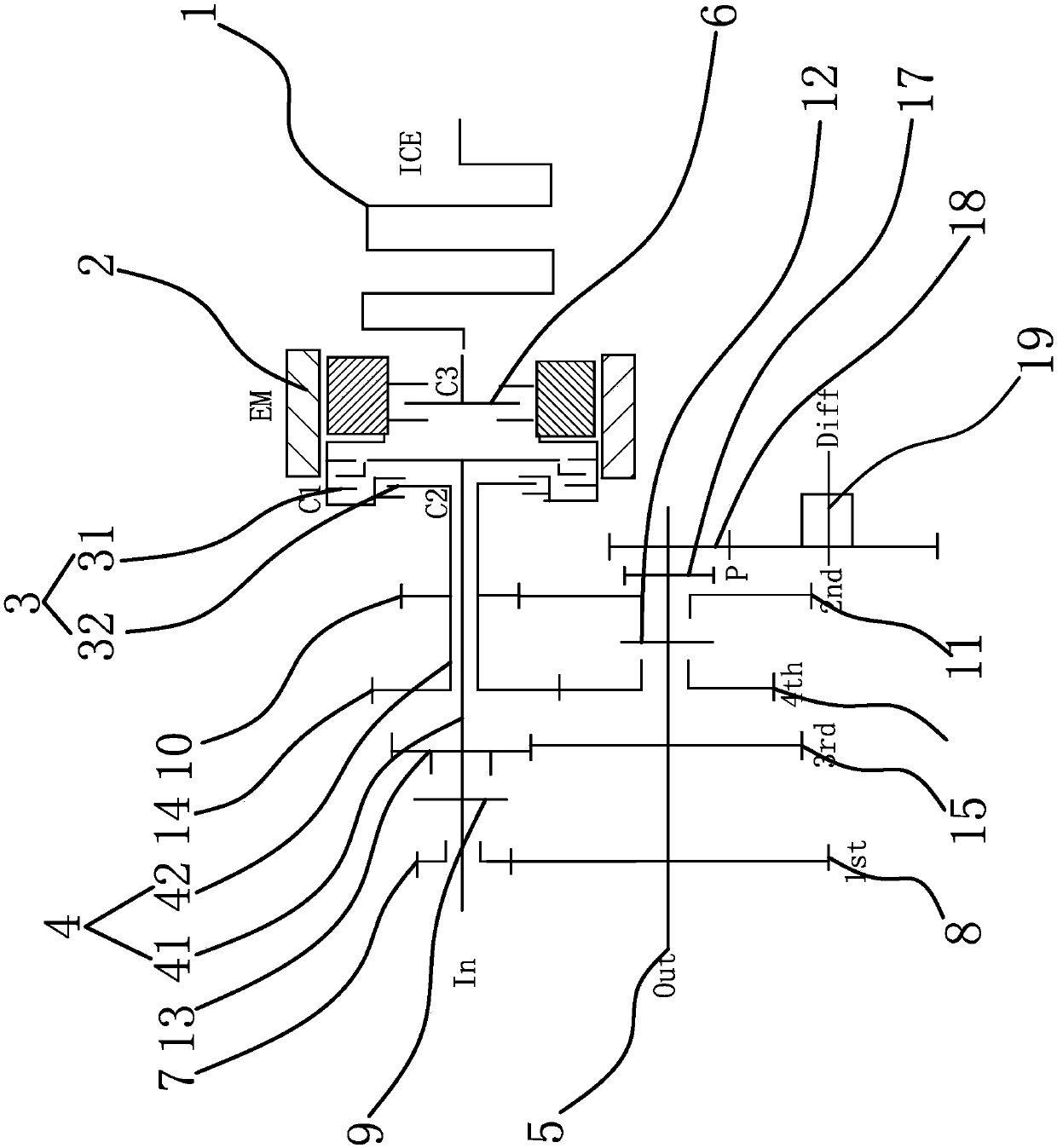

[0026] The technical solution in this embodiment is basically the same as the technical solution in Embodiment 1, the difference is that, as figure 2 As shown, in this embodiment, the gear gear structure includes the first-speed driving gear 7 and the third-speed driving gear 13 that are rotatably connected to the first input shaft 41, and the second-speed driving gear that is fixedly connected or integrally formed on the second input shaft 42. 10 and the fourth gear driving gear 14 and the first gear driven gear 8, the second gear driven gear 11 integrally formed or fixedly connected on the output shaft 5, the third gear driven gear 15 and the fourth gear driven gear 11 that are rotationally connected on the output shaft 5 Driven gear 16, the first gear driving gear 7 meshes with the first gear driven gear 8, the second gear driving gear 10 meshes with the second gear driven gear 11, the third gear driving gear 13 meshes with the third gear driven gear 15, and the fourth gear...

Embodiment 3

[0028] The technical solution in this embodiment is basically the same as the technical solution in Embodiment 1, the difference is that in this embodiment, there is only one input shaft 4, and the driving gears of all gears are located on the input shaft 4. There is only one shaft clutch 3, and the gear gear structure includes a first-speed driving gear 7 and a second-speed driving gear 10 fixedly connected or integrally formed on the input shaft 4, and a first-speed driven gear connected to the output shaft 5 through bearing rotation. 8 and second gear driven gear 11. The first gear driving gear 7 meshes with the first gear driven gear 8, and the second gear driving gear 10 meshes with the second gear driven gear 11. The output shaft 5 is also fixedly connected with a synchronizer 9 that can make the first gear driven gear 8 or the second gear driven gear 11 be connected with the output shaft 5 by a spline, and the output shaft 5 is also fixedly connected with the parking ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com