Preparation method of moisture absorption heat preservation obstruction air layer style knitted fabric

A technology of blocking air and knitting fabrics, applied in the field of knitted fabrics, which can solve the problems of single style, limited improvement of heat preservation function, and needs to be improved, so as to achieve good moisture absorption and various styles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

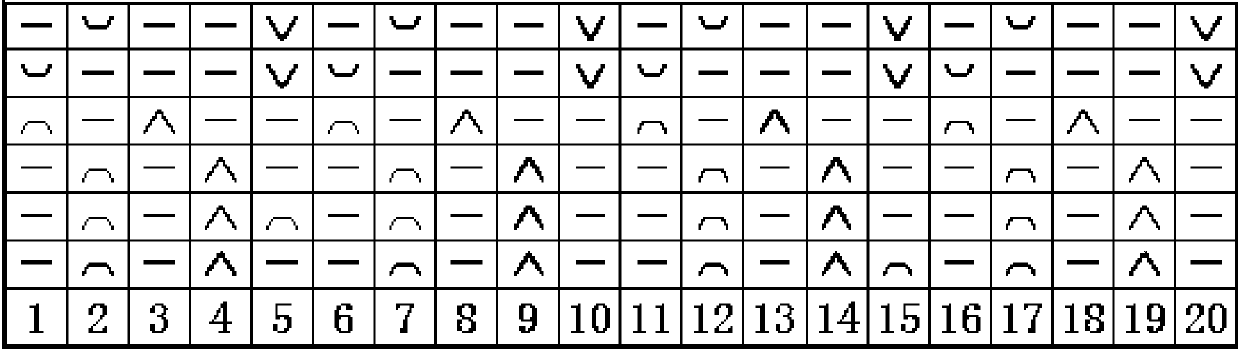

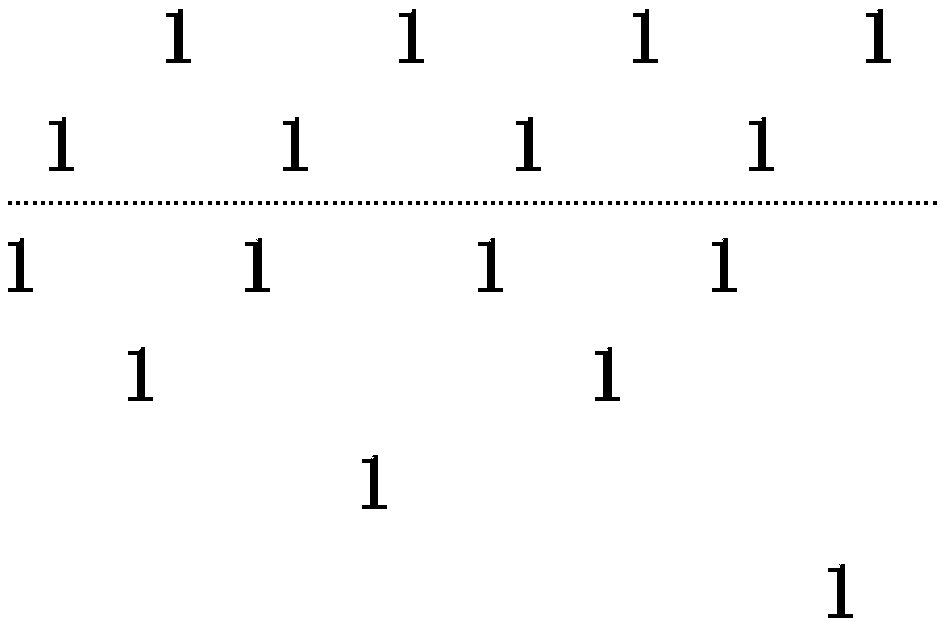

[0029] Example 1, such as figure 1 and figure 2 As shown, a method for preparing a moisture-absorbing, warm-keeping and air-blocking style knitted fabric, the fabric includes a surface yarn, an air layer yarn and a bottom yarn, and further includes the following steps. Step A: Select the surface yarn as Siro compact spinning, select the air layer yarn as full polyester hollow fiber yarn, select the bottom yarn as polyester, and then weave the surface yarn, air layer yarn and bottom yarn into a mesh-type air yarn through weaving equipment. In the 20-way triangular structure, the 20-way triangular structure is evenly divided into four cycles, wherein the first cycle of the first cycle, the first cycle of the second cycle, the first cycle of the third cycle and the first cycle of the fourth cycle One way is floating thread, looping, looping, floating thread, floating thread, floating thread weaving structure loop, the second loop of the first loop, the second loop of the second...

Embodiment 2

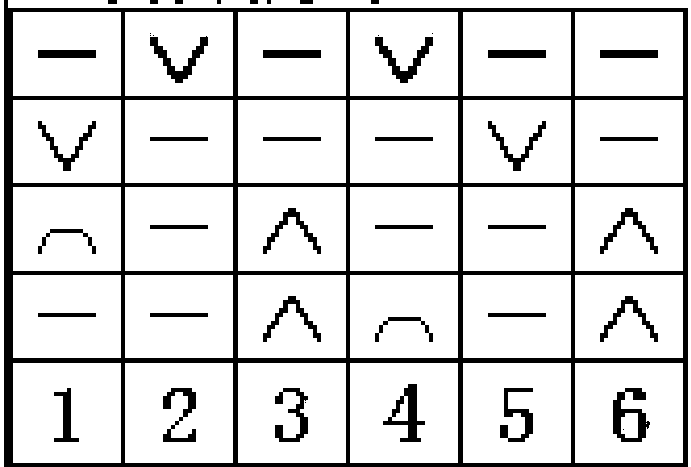

[0031] Example 2, such as image 3 and Figure 4 As shown, a method for preparing a moisture-absorbing, warm-keeping and air-blocking style knitted fabric, the fabric includes a surface yarn, an air layer yarn and a bottom yarn, and further includes the following steps. Step A: Select the surface yarn as a blend of long-staple cotton and siro compact spinning, select the air layer yarn as coffee carbon fiber, select the bottom yarn as spandex, and then weave the surface yarn, air layer yarn and bottom yarn into napped yarns through weaving equipment. For the fabric blank of air-like layer, in the 6-way triangular structure, coffee carbon fiber is used for the 1st, 2nd, 4th, and 5th roads. Tuck, float, float, float weaving structure cycle, the 4th road is tuck, float, float, loop weaving structure cycle, the 5th road is float, tuck, float, float weaving Structural circulation, the third way uses long-staple cotton and Siro compact blending, the third way is floating thread, f...

Embodiment 3

[0033] Example 3, such as Figure 5 and Figure 6 Shown is a method for preparing a moisture-absorbing, warm-keeping and air-blocking style knitted fabric. The fabric includes surface yarns, intermediate yarns and bottom yarns, and further includes the following steps. Step A: Select the surface yarn as polyester, select the middle yarn as spandex covered yarn, select the bottom yarn as polyester-cotton blend, and then weave the surface yarn, air layer yarn and bottom yarn into a cushion-like air layer through weaving equipment. For the fabric blank, in the 3-way triangular structure, the first line uses spandex covered yarn, the first line is the cycle of tuck, tuck, forming, and lifting weaving structure, the second line uses polyester, and the second line is floating thread, floating Thread, interlining and weft weaving structure cycle, jersey cloth is selected for the third way, and floating thread, floating thread, tuck, tuck weaving structure cycle is the third way. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com