Calcium sand foundation carbon dioxide strengthening technology

A carbon dioxide, foundation reinforcement technology, applied in infrastructure engineering, soil protection, construction, etc., can solve the problems of high transportation cost and inconvenient material acquisition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

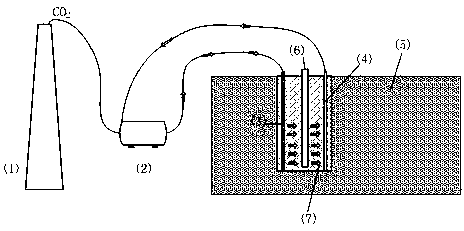

[0012] The embodiment of the method for reinforcing carbon dioxide acidified calcareous sand foundation of the present invention will be further described below with reference to the accompanying drawings:

[0013] figure 1 It is a schematic diagram of a method for strengthening carbon dioxide acidified calcareous sand foundation. The method for implementing foundation reinforcement using the technology of the present invention is as follows:

[0014] a) Capture the carbon dioxide emitted by the carbon dioxide emission source (1). Fill the water and calcareous sand into the high-pressure vessel (2), and pass the carbon dioxide captured by the carbon dioxide emission source (1) to react the carbon dioxide, water, and calcareous sand to generate a calcium bicarbonate solution;

[0015] b) Arrange the injection well (3) and the discharge well (4) in the area to be reinforced (7), and inject the calcium bicarbonate solution into the area to be reinforced (7) through the injection well (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com