Heat-resistant aramid fiber synchronous belt and preparation method thereof

A technology of aramid fiber and timing belt, which is applied in coating and other directions, can solve the problems of fast performance loss of timing belt, lack of targeted research, and poor stability of timing belt, so as to improve stability and mechanical resistance, accelerate construction, The effect of improving tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

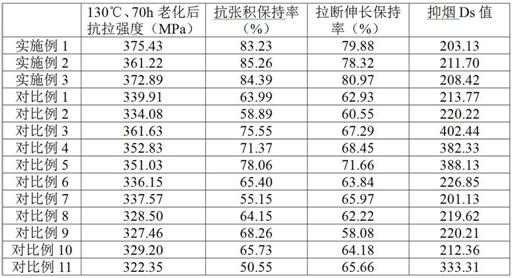

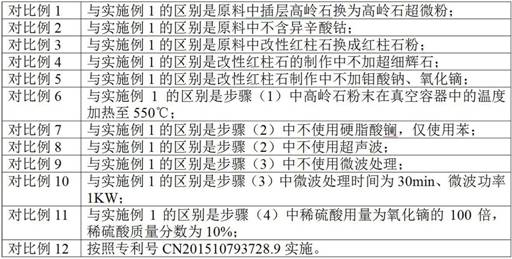

Examples

Embodiment 1

[0034] A heat-resistant aramid fiber synchronous belt, prepared from the following raw materials: 15 parts of acrylic cheese rubber, 35 parts of hydrogenated nitrile rubber, 50 parts of silicone rubber, 1 part of intercalated kaolinite, alkyl dithiocarbamic acid 0.5 parts of zinc, 0.3 parts of cobalt isooctanoate, 5 parts of polyvinyl chloride, 23 parts of epoxy resin, 10 parts of aramid fiber mesh, 8 parts of glass fiber core wire, 8 parts of cyanate resin, 1 part of modified andalusite, 1 part of superfine pyroxene, 3 parts of phenylenediamine, 2 parts of dodecyl tertiary amine, described intercalation kaolinite is made of kaolinite superfine powder and lanthanum stearate with a mass ratio of 10:1; The modified andalusite is made of andalusite, sodium molybdate and dysprosium oxide with a mass ratio of 21:3:1.

[0035] The preparation method of the heat-resistant aramid fiber synchronous belt described in this embodiment is as follows:

[0036] (1) kaolinite interlayer acti...

Embodiment 2

[0051] A heat-resistant aramid fiber timing belt, prepared from the following raw materials: 20 parts of acrylic cheese rubber, 55 parts of hydrogenated nitrile rubber, 80 parts of silicone rubber, 3 parts of intercalated kaolinite, alkyl dithiocarbamic acid 1 part of zinc, 0.5 parts of cobalt isooctanoate, 8 parts of polyvinyl chloride, 35 parts of epoxy resin, 15 parts of aramid fiber mesh, 11 parts of glass fiber core wire, 13 parts of cyanate resin, 3 parts of modified andalusite, 1.5 parts of superfine pyroxene, 5 parts of phenylenediamine, 4 parts of dodecyl tertiary amine, described intercalation kaolinite is made from kaolinite superfine powder and lanthanum stearate that mass ratio is 14:2; The modified andalusite is made of andalusite, sodium molybdate, and dysprosium oxide with a mass ratio of 25:5:2.

[0052] The preparation method of the heat-resistant aramid fiber synchronous belt described in this embodiment is as follows:

[0053] (1) kaolinite interlayer acti...

Embodiment 3

[0068] A heat-resistant aramid fiber synchronous belt, prepared from the following raw materials: 19 parts of acrylic cheese rubber, 45 parts of hydrogenated nitrile rubber, 66 parts of silicone rubber, 2 parts of intercalated kaolinite, alkyl dithiocarbamic acid 1 part of zinc, 0.3 parts of cobalt isooctanoate, 8 parts of polyvinyl chloride, 23 parts of epoxy resin, 15 parts of aramid fiber mesh, 13 parts of glass fiber core wire, 8 parts of cyanate resin, 3 parts of modified andalusite, 1 part of superfine pyroxene, 5 parts of phenylenediamine, 2 parts of dodecyl tertiary amine, described intercalation kaolinite is made of kaolinite superfine powder and lanthanum stearate with a mass ratio of 14:1; The modified andalusite is made of andalusite, sodium molybdate, and dysprosium oxide in a mass ratio of 25:3:2.

[0069] The preparation method of the heat-resistant aramid fiber synchronous belt described in this embodiment is as follows:

[0070] (1) kaolinite interlayer activ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com