Single-rotation-direction four-oil-wedge inner hole heavy-load sliding bearing

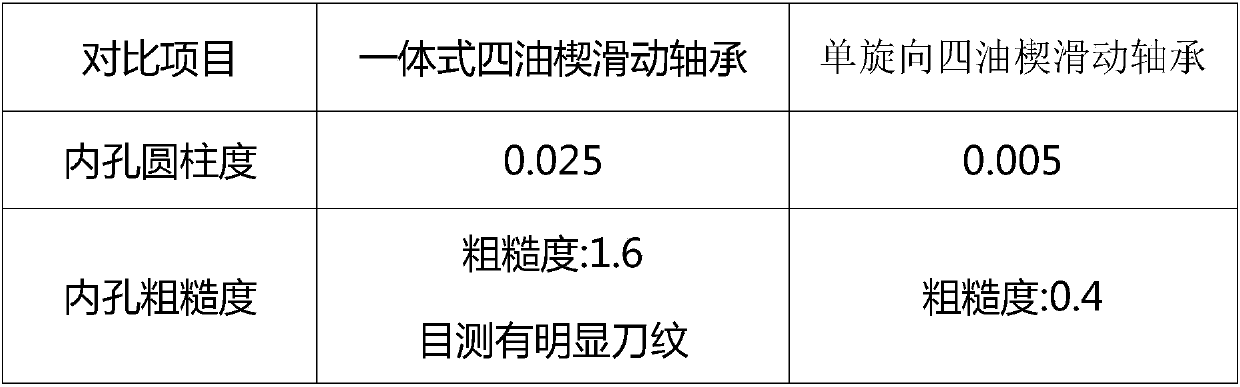

A technology of sliding bearings and bearings, which is applied in the direction of bearings, bearing components, shafts and bearings, etc., can solve the problems of difficult processing, difficult measurement, large damping, etc., and achieve the effects of large anti-oil film oscillation ability, good centering and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

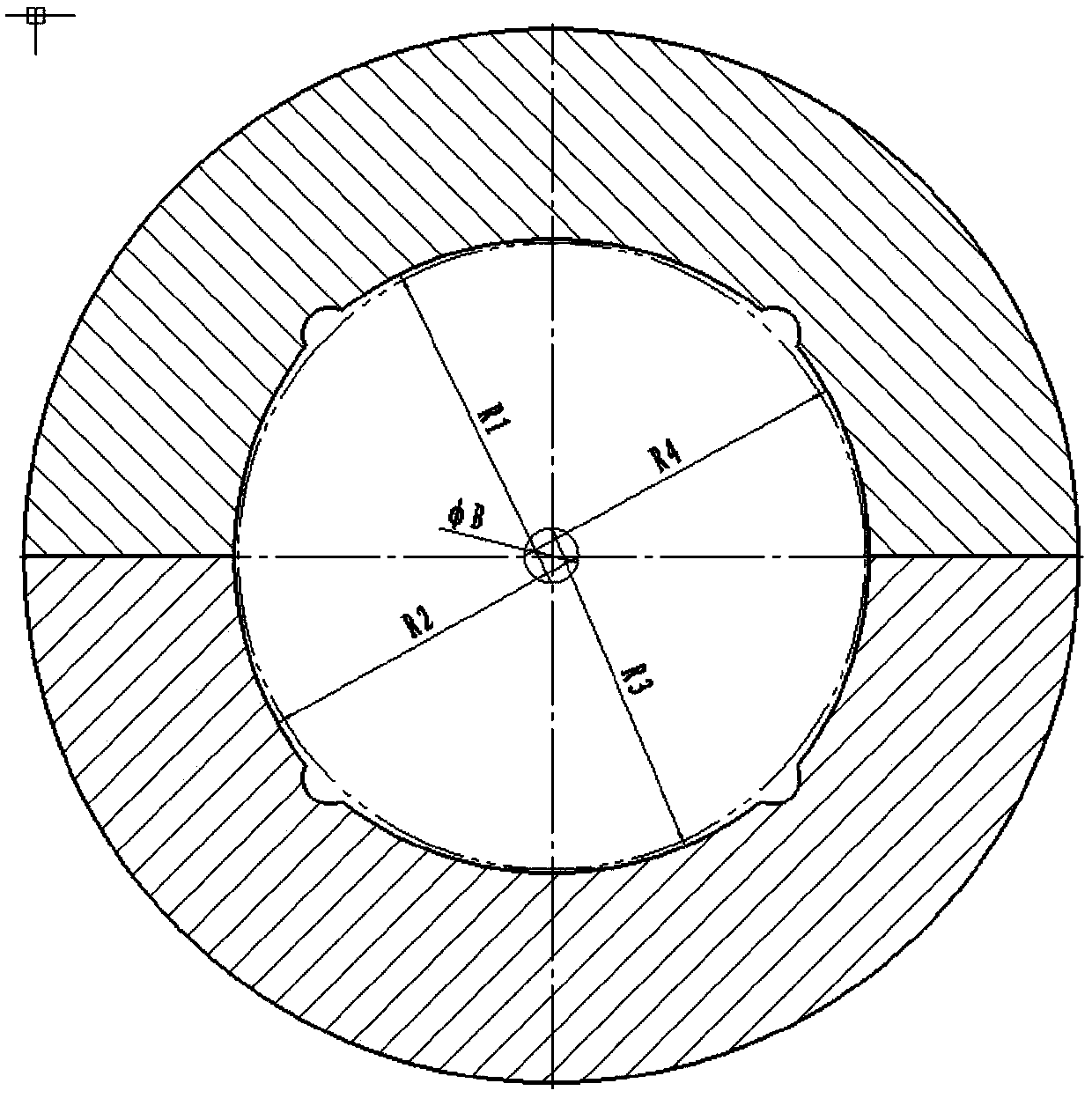

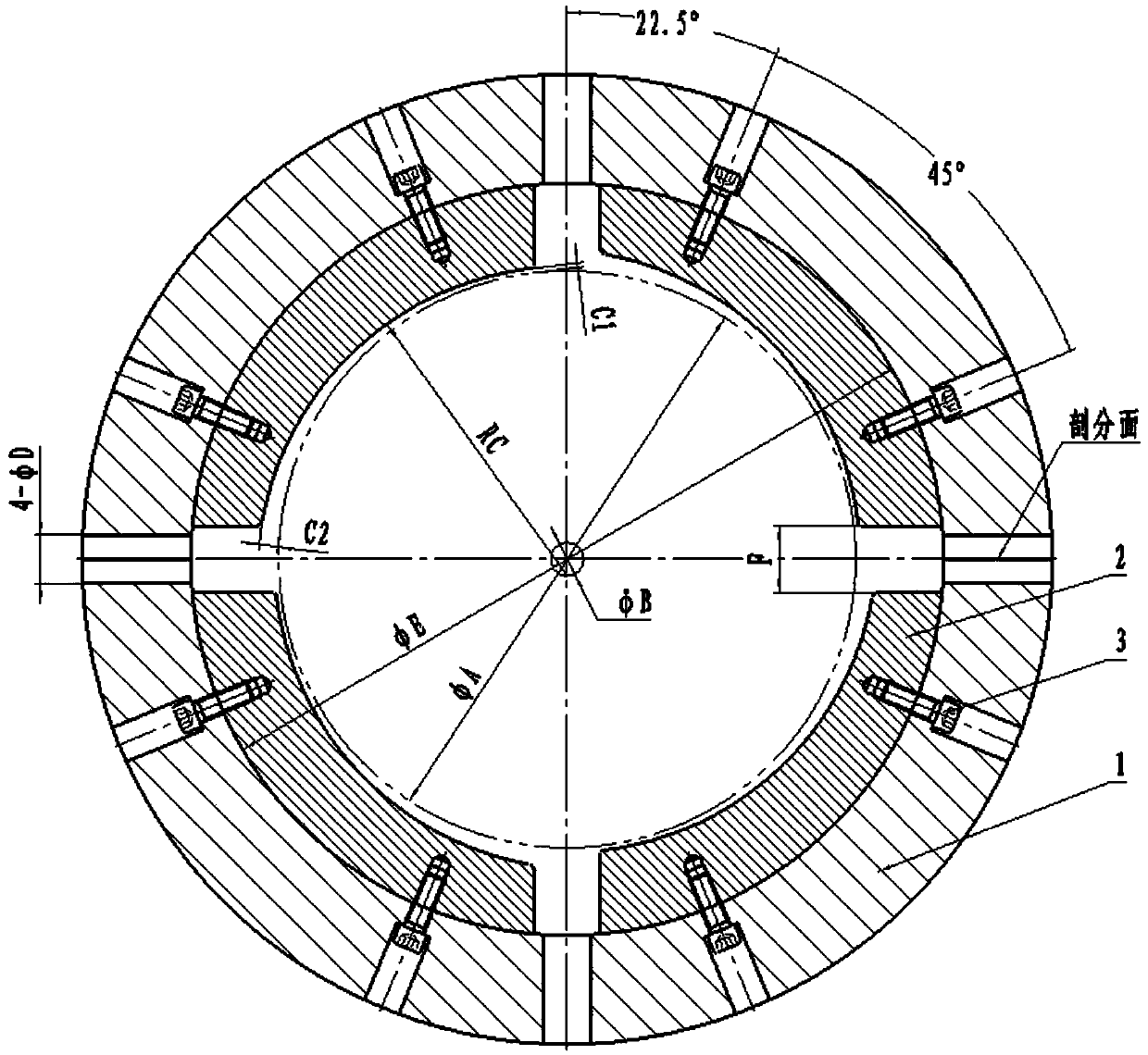

[0015] refer to figure 2 , single-rotation four-oil-wedge bore heavy-duty sliding bearing, including bearing body 1, the material of bearing body 1 is 45# quenched and tempered steel, bearing body 1 is divided into upper bearing body and lower bearing body, and the lower bearing body is installed in the bearing of the lower box In the seat, the upper bearing body is installed in the bearing seat of the upper box; the upper and lower bearing bodies are connected together by screws and cylindrical pins, and four tiles 2 are installed in the inner hole of the bearing body 1 through screws 3; the upper bearing body 1 It is designed with 4 oil inlet holes φD running through the inner and outer circles, which are distributed between the tiles 2 to ensure the oil supply of the tiles, and finally form a single-rotation four-oil wedge inner hole slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com