Drying device for paperboards

A drying device and cardboard technology, which is applied in the directions of drying gas arrangement, drying solid materials, drying goods processing, etc., can solve the problems of easy deformation of cardboard, unsatisfactory cardboard quality, low drying efficiency, etc., and achieves improved quality, simple structure, drying Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

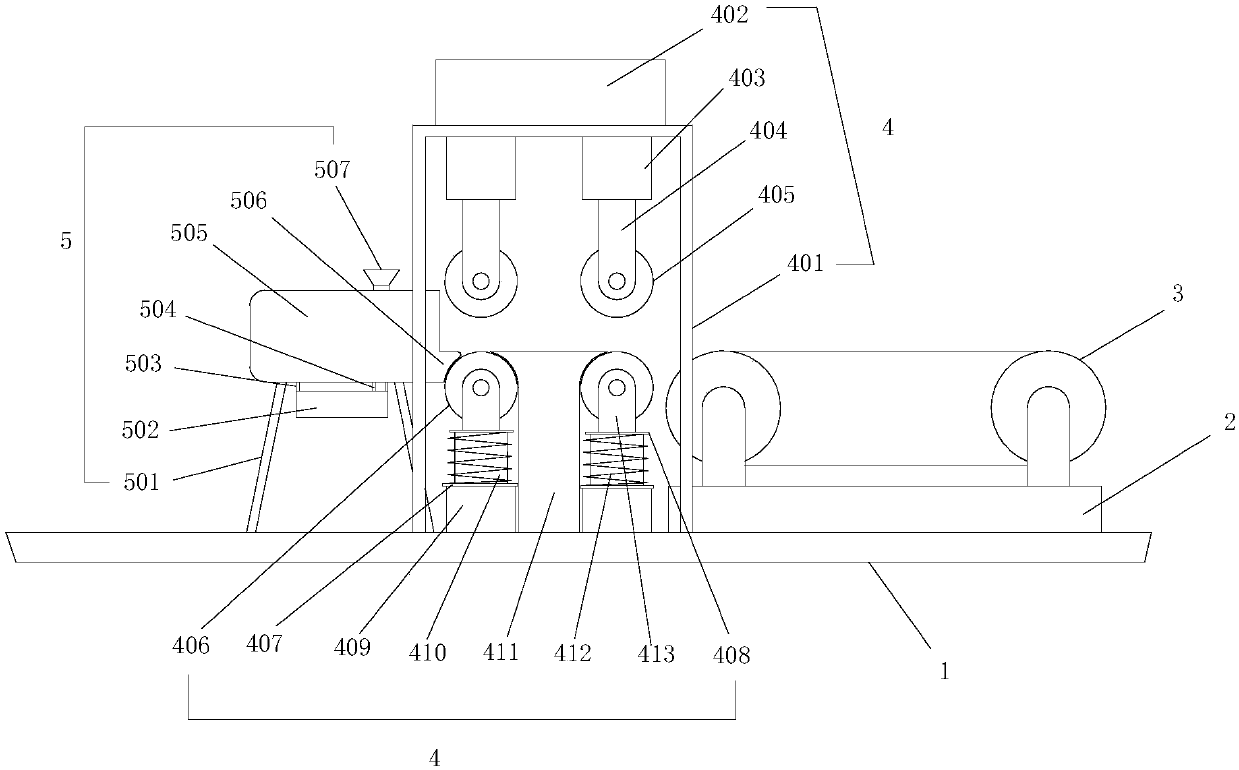

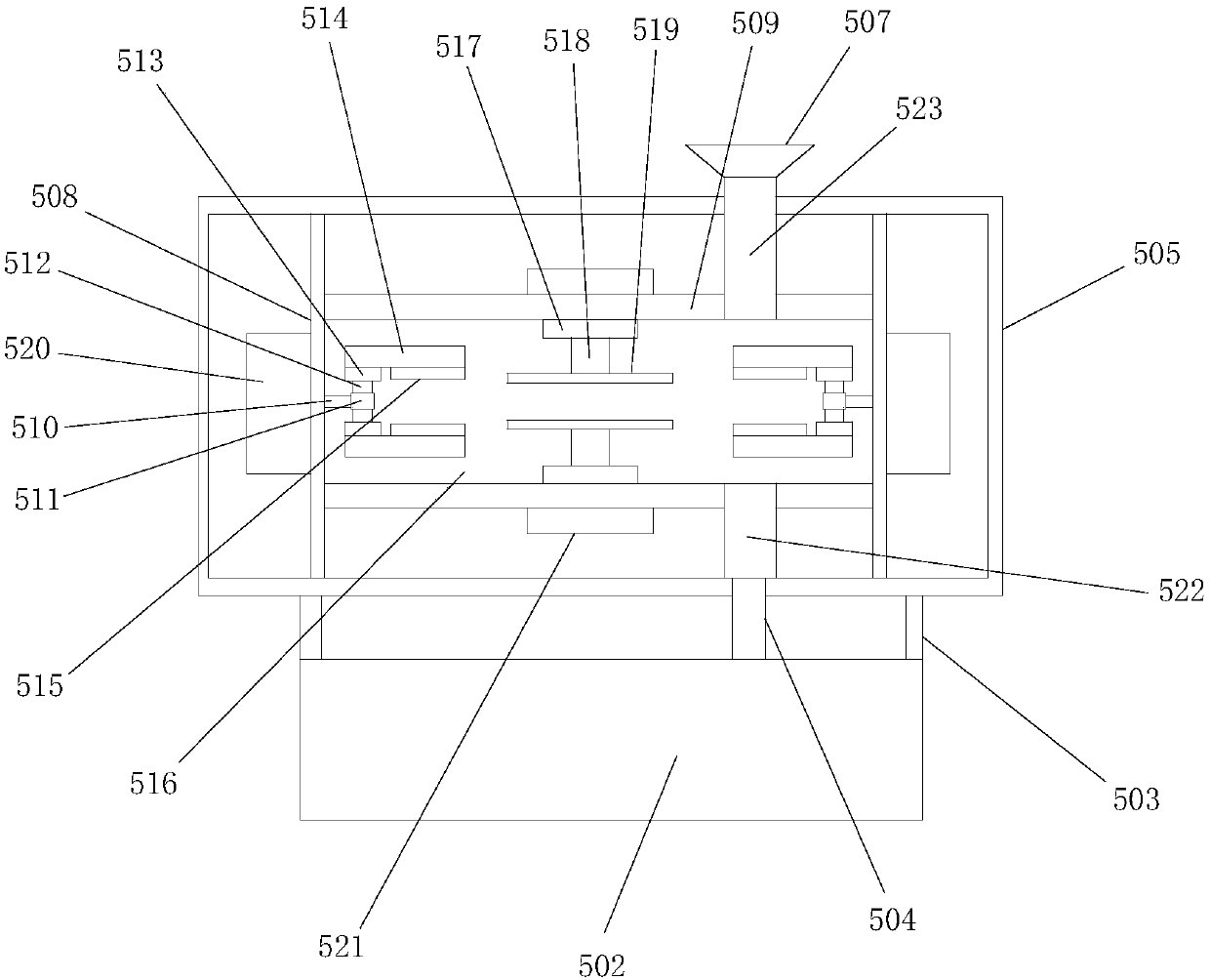

[0030] like Figure 1-2 As shown, the present invention provides a cardboard drying device, including a base 1, a first motor 2, a conveyor 3, a limiting mechanism 4 and a drying mechanism 5, and the base 1 is sequentially installed with a conveyor 3, a limiting mechanism 4 and a drying mechanism. Mechanism 5, the first motor 2 for driving the conveyor 3 is installed on the upper end of the base 1, the drying mechanism 5 includes a second mounting bracket 501, a hot air box 502, an air inlet pipe 504, a drying box 505 and an air outlet 507, and the upper end of the base 1 passes through The second mounting bracket 501 is equipped with a drying box 505, the second mounting bracket 501 upper end is equipped with a drying box 505, the drying box 505 lower end is equipped with a hot air box 502 through the hot air box mounting frame 503, and the hot air box 502 is connected to the drying box through the air inlet pipe 504. 505 is connected, the upper end of the drying box 505 is p...

Embodiment 2

[0037] The difference between Embodiment 2 of the present invention and Embodiment 1 above is that.

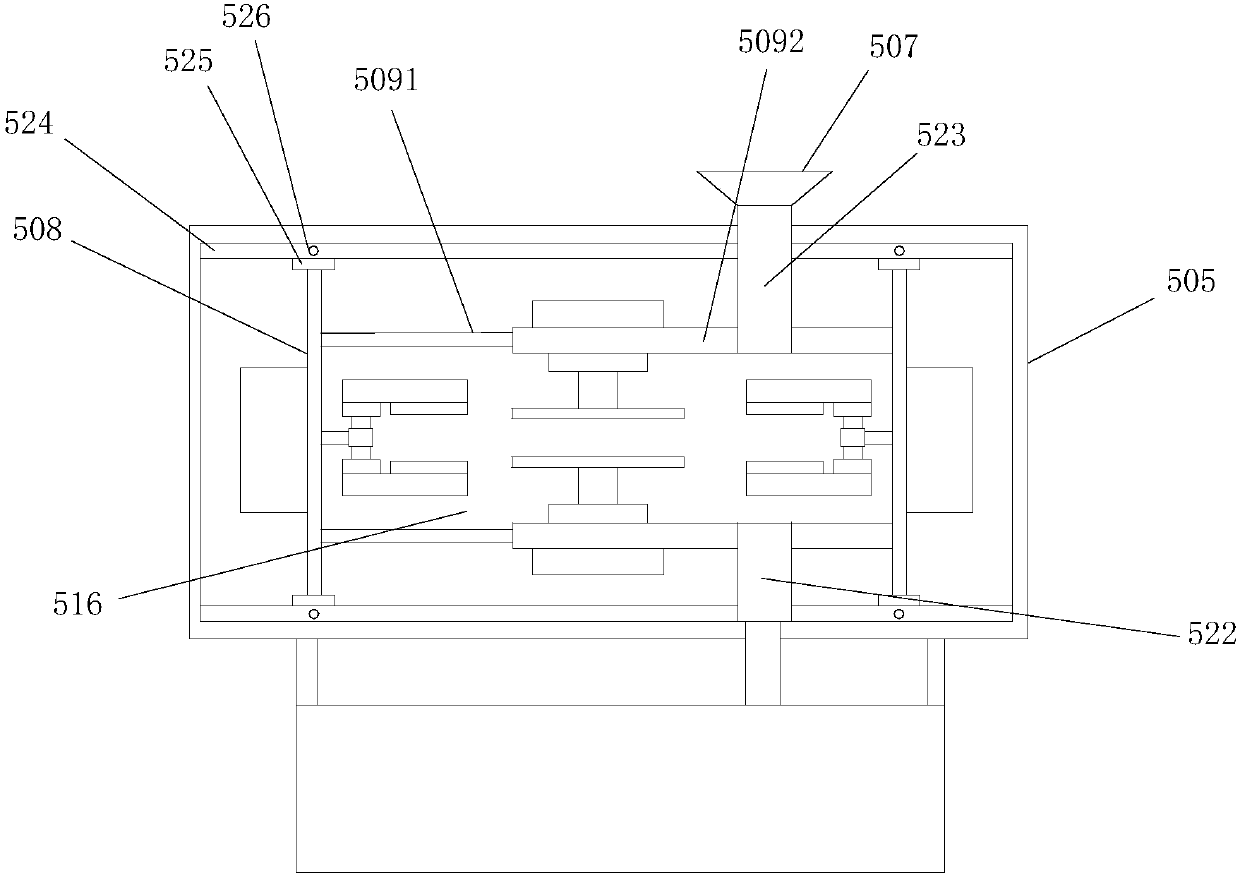

[0038] refer to image 3 , the horizontal shaft 509 is composed of the third piston shaft 5091 and the third piston 5092, the third piston shaft 5091 and the third piston 5092 are installed between the vertical shaft 508, the fourth motor 521 and the fifth piston 517 are installed on the third piston On the 5092, a chute 524 is provided on the drying box 505 inwall, and a chute 524 is installed on the drying box 505 inwall, and a slide block 525 is installed on the chute 524 by a pulley 526, and the slide block 525 and the vertical shaft 508 are fixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com