Braking flutter inhibition method based on chassis angle assembly transient dynamics

A dynamic and chattering technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as high cost and limited feasibility, and achieve the effect of low cost, low improvement cost and high feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

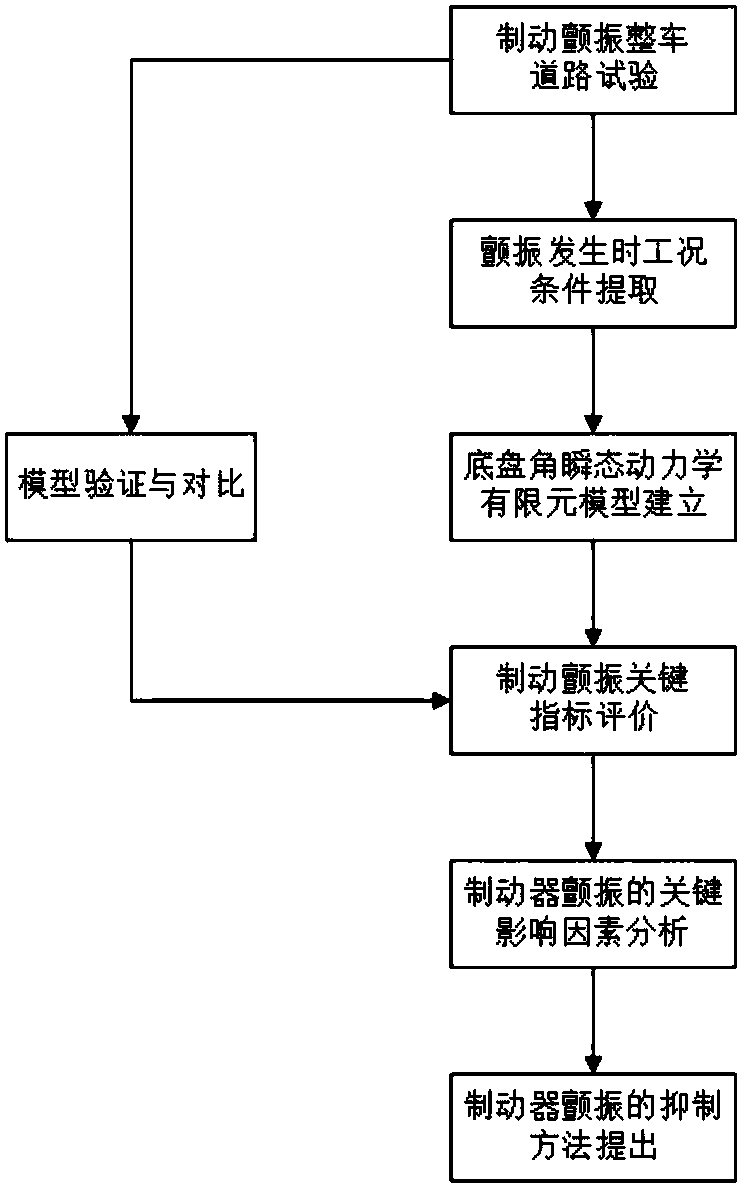

[0053]A brake chatter suppression method based on the transient dynamic analysis of the chassis corner assembly, which can reproduce the brake chatter phenomenon, and proposes effective measures to suppress the brake chatter. Its overall process is as follows figure 1 shown, including the following steps:

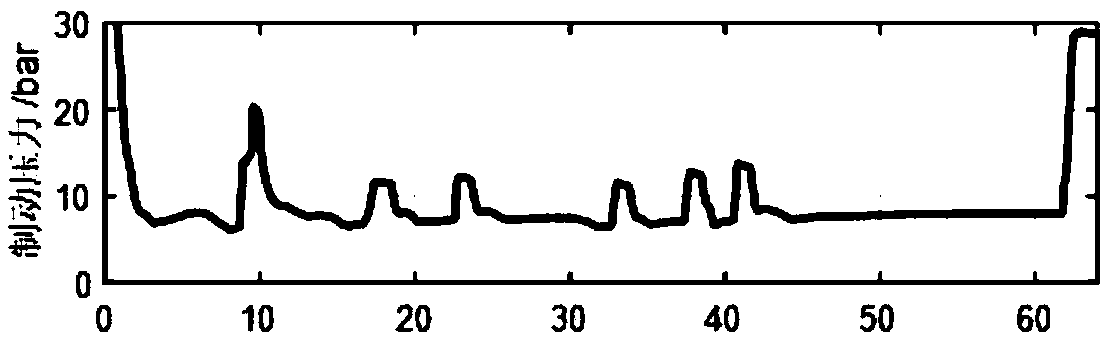

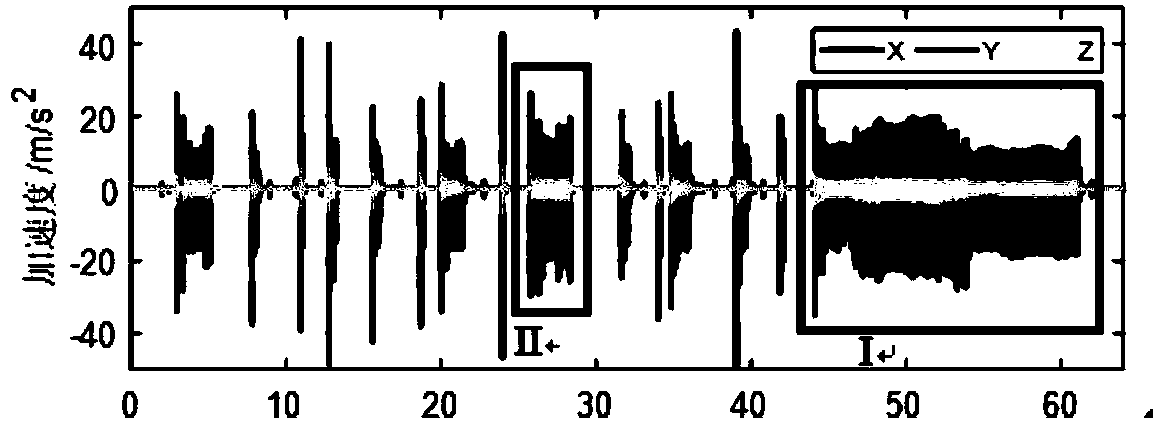

[0054] Step 1: Carry out the road test of the whole vehicle, and collect signal data such as brake oil pressure, wheel speed, noise sound pressure level at the driver's ear, and three-way acceleration of the brake caliper. The noise at the side of the driver's ear is collected by a sound level meter fixed on the headrest. The acceleration sensor of the brake caliper is installed on the end surface of the piston side of the brake caliper, and the oil pressure sensor is connected in series in the front brake pipeline.

[0055] Step 2: Analyze and process the test data obtained from the vehicle road test, and obtain the change characteristics of brake pressure, brake caliper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com