Dual-drive heavy type transport cart

A heavy-duty transport vehicle, dual-drive technology, used in transportation and packaging, vehicle accessories, vehicle components, etc., can solve problems such as no feedback system for engine speed and load changes, and unsatisfactory synchronization effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with embodiment the present invention will be further described, but the present invention is not limited to these examples, under the premise of departing from the gist of the present invention, any improvement made falls within the protection scope of the present invention.

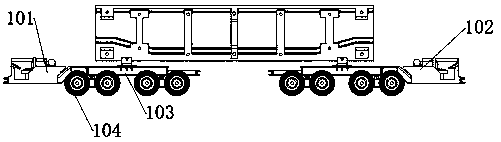

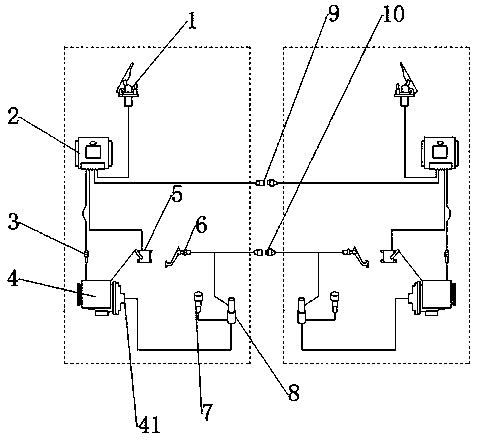

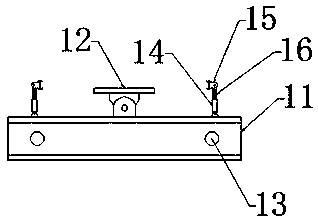

[0025] As shown in the figure, a double-drive heavy-duty transport vehicle of the present invention includes an active vehicle 101 and a passive vehicle 102. Both the active vehicle and the passive vehicle include a pedal electronic throttle 1, an ECU speed controller 2, an engine The speed sensor 3, the engine 4, the clutch oil cylinder 41 arranged on the engine, the servo throttle actuator 5, the clutch potentiometer 6, the clutch hydraulic pot 7, the clutch electric pump 8, the speed communication joint 9 and the clutch potential signal joint 10, the The foot-operated electronic throttle is connected with the ECU speed controller, and the throttle opening signal is sent to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com