Fin-type field-effect tube and forming method therefor

A technology of fin field effect transistors and fins, which is applied in the direction of transistors, electrical components, electric solid devices, etc., can solve the problems that the electrical performance of fin field effect transistors needs to be improved, achieve good lattice integrity, and improve electrical performance , the effect of good electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] It can be seen from the background art that the electrical performance of the fin field effect transistor formed in the prior art needs to be improved. This problem is more significant for N-type fin field effect transistors. Analyze the reasons for this:

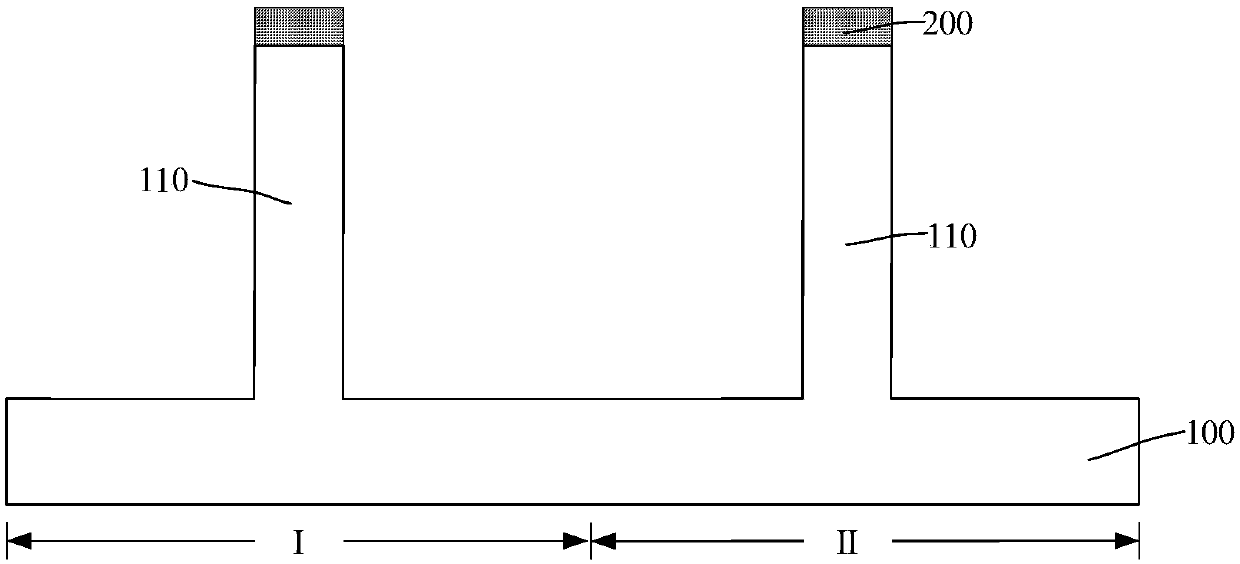

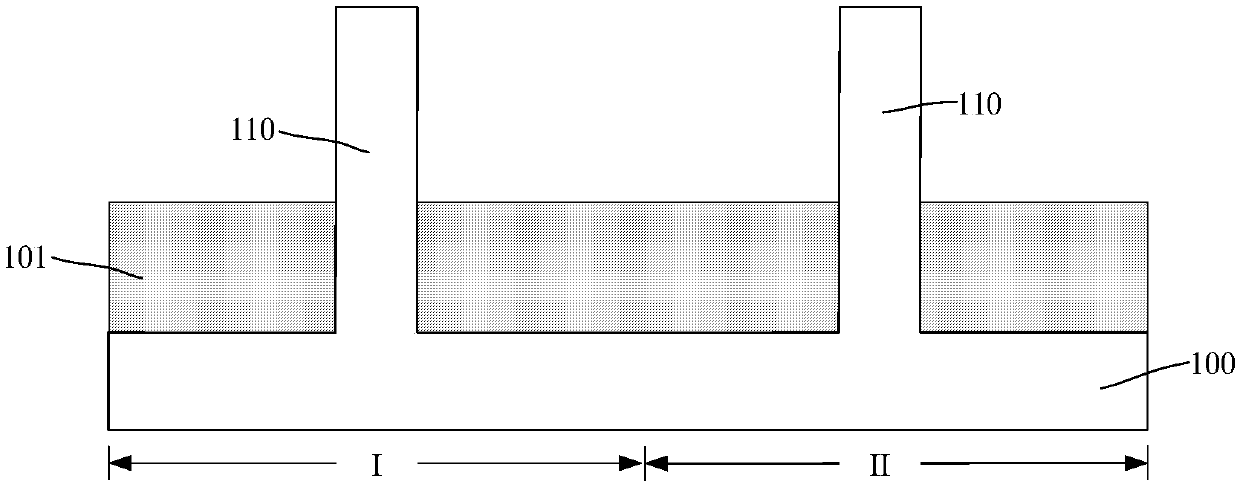

[0014] combined reference figure 1 , showing an electron microscope image of a fin field effect transistor. For an N-type fin field effect transistor, the current main formation method includes forming recesses in the fins 10 on both sides of the gate structure (not shown). A groove (not shown in the figure); an in-situ doped epitaxial layer 20 is formed in the groove by a selective epitaxy process, and the in-situ doped epitaxial layer 20 has N-type dopant ions.

[0015] However, since the surface of the fin portion 10 exposed by the groove has a crystal orientation, during the selective epitaxy process, the in-situ doped epitaxial layer 20 grows along the crystal orientation; and The crystal orientation is di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com