Centrifugal fish feeder

A centrifugal and logic controller technology, applied in the field of fish feeders, can solve the problems of increasing motor power, increasing energy consumption, and single angle, and achieves the effects of increasing centrifugal force, easy assembly, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

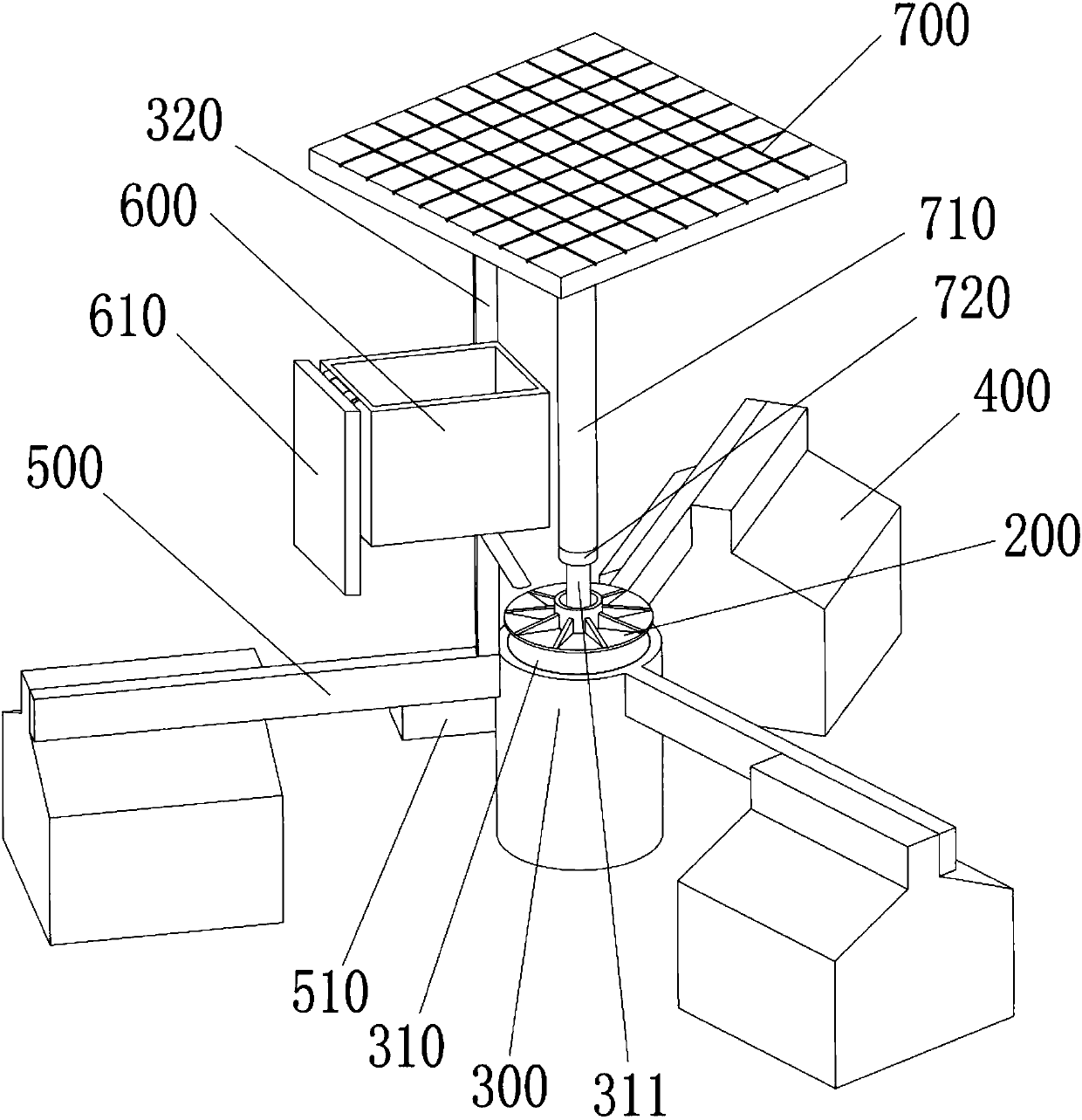

[0033] Such as figure 1 - As shown in the figure, a centrifugal fish feeder is characterized in that it includes a connection base 300, a cavity 310 for accommodating a motor and a power supply is provided in the connection base 300, and several buoys 400 are included to float the connection base 300 on the water surface , the connection seat 300 is fixedly connected with the buoy 400 through the strut 500, including the tray assembly for feeding, the tray assembly is fixedly connected with the output shaft 311 of the motor, when the motor is working, the tray assembly rotates to realize feeding, the strut 500 and the buoy 400 It can be fixed by screws. The tray assembly includes a base body 100 and a tray 200 , which are collectively referred to as a tray assembly here.

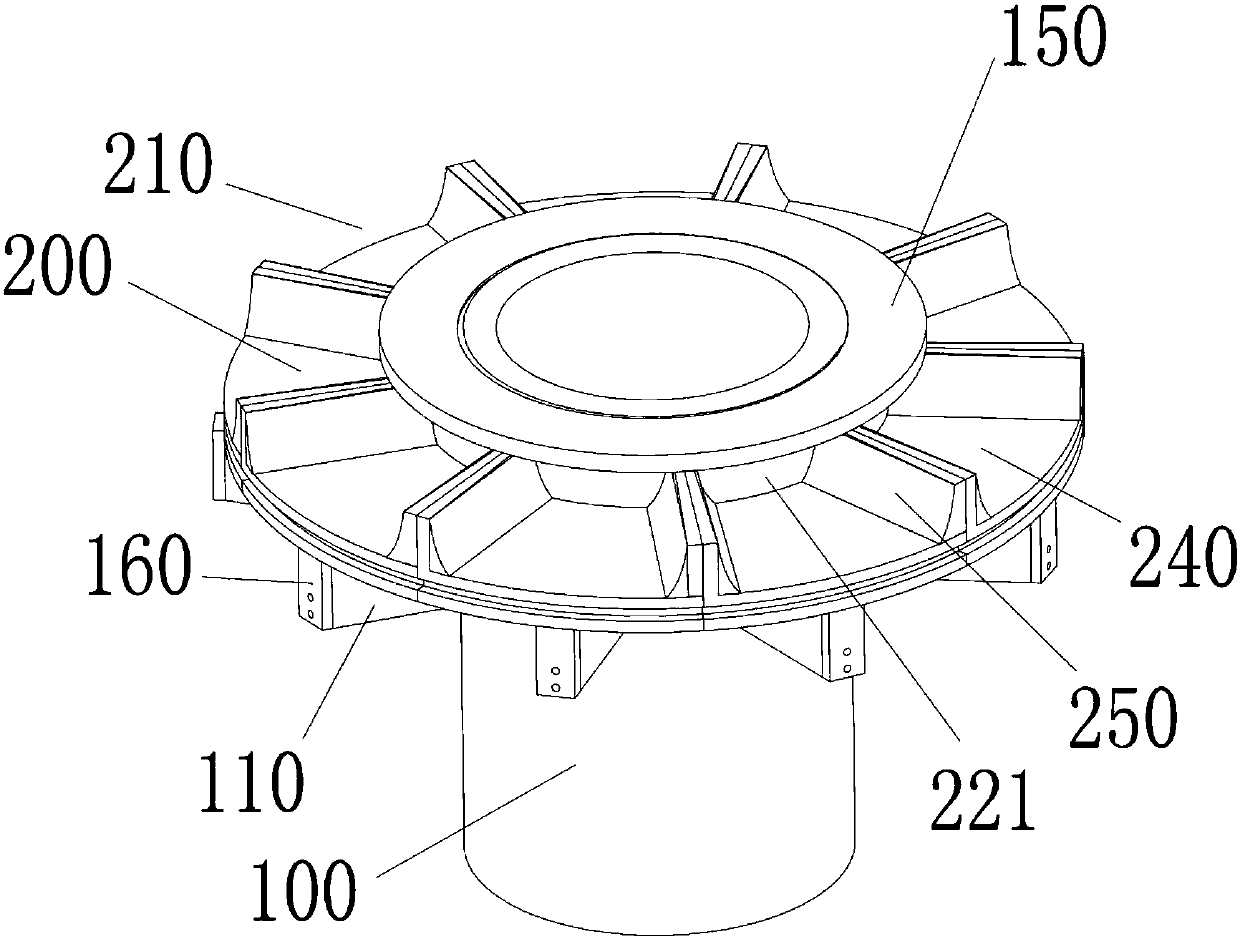

[0034] The tray assembly includes a seat body, the seat body 100 is a hollow tubular structure, the side wall of the seat body 100 is provided with several symmetrical guide rails 110, and the guide rails 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com