Bar-type baking and squeezing integrated machine for sugarcanes

An all-in-one machine, sugarcane technology, applied in the press, juice extraction, food processing and other directions, can solve the problems of low efficiency, uneven heating, slow processing speed, etc., to achieve the effect of convenient operation, efficiency saving and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Now do further detailed explanation in conjunction with accompanying drawing.

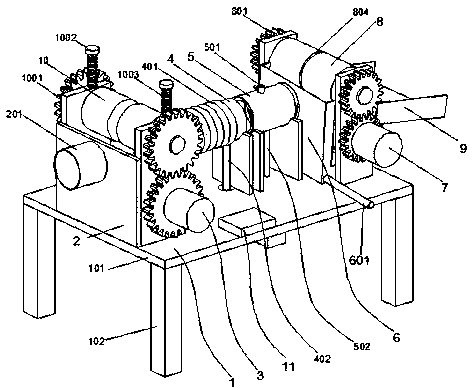

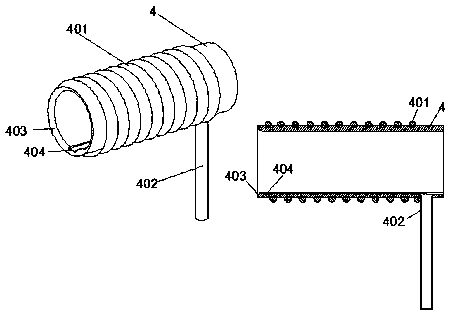

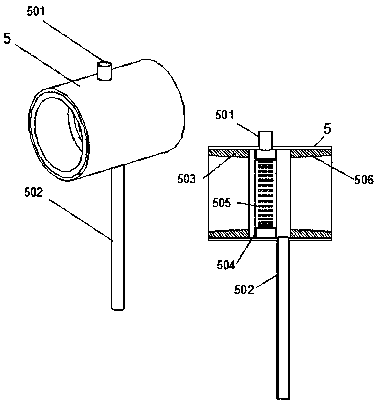

[0020] Such as Figures 1 to 4 As shown, a sugarcane strip roasting and pressing machine includes a frame 1, a feed plate 2, a motor 3, a heating cylinder 4, a cleaning cylinder 5, a juice receiving box 6, a B motor 7, a pressing wheel 8, and a slag receiving Bucket 9, feeding wheel 10 and PLC11.

[0021] Such as Figure 1-4 As shown, the setting frame 1 is provided with a mounting plate 101 and 4 feet 102, 101 of the mounting plate. The feeding wheel 10 is set to be divided into upper and lower wheels and installed on the left end of the rack mounting plate 101. The A motor 3 drives the lower wheel to rotate, and the upper wheel is driven by the gear 1001. Screws 1102 are arranged on both sides of the center of the upper wheel, and a spring 1103 is set inside the screw 1102. , the feed plate 2 is installed on its left side, and the heating cylinder 4 is installed in the center of the rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com