A method for improving the quality of tobacco stems

A technology of tobacco stems and nicotine, which is applied in the fields of tobacco, tobacco processing, application, etc., can solve the problems of unclear and lacking storage and alcoholization purposes, time, etc., and achieve the effects of improving sensory quality, alleviating constraints, and improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

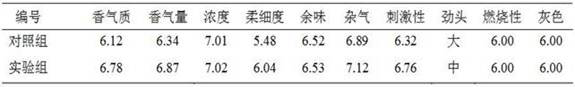

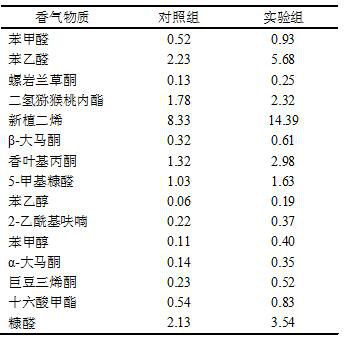

Examples

Embodiment 1

[0027] A method for improving the quality of tobacco stems, comprising the steps of:

[0028] 1) Screen the tobacco stems, and remove the broken tobacco stems with a length of less than 10mm and a diameter of less than 1.5mm, and wash the selected tobacco stems in a stem washing machine. The parameters for washing stems are as follows: Tobacco stems The falling water speed is 5m / s, the water temperature is controlled at 35°C, the water speed is 2m / s, the number of filter screens is 25.416 mesh (25.4mm), the screen angle is 30°, the water filtration time is 7s, and the circulating water is replaced every 3 hours. Ozone is passed into the water tank of the stem washing machine to carry out ozone treatment on the tobacco stems after washing for 30 minutes. The ozone is produced by an ozone generator, and the ozone concentration is 350 mg / L. Dry;

[0029] 2) Turn on the far-infrared radiation source, and perform far-infrared radiation treatment on the dried tobacco stems in step ...

Embodiment 2

[0046] The difference between the method of this example and Example 1 is that the parameters for washing the stems in step 1) are: the water temperature of the tobacco stems falls into the water at a speed of 4.6m / s, and the water temperature is controlled at 33°C, and the water speed is 1.5m / s. mm) Filter screen angle 28° Filtration time 7s Replace circulating water every 2h Ozone treatment time is 20min, ozone concentration is 300 mg / L; The intensity of irradiation was 100W, and each irradiation was 10s; the tobacco stems treated with enzymes in step 3) were stored for 2 hours.

Embodiment 3

[0048] The difference between the method of this example and Example 1 is that the parameters for washing the stems in step 1) are: the falling speed of tobacco stems is 4.8m / s, the water temperature is 34°C, the water speed is 2.5m / s, and the water filtration time is 8s; step 2) COSCO The intensity of infrared radiation is 300W, and the tobacco stems are irradiated 4 times, each irradiation is 15s, and the interval of each irradiation is 7.5min; the enzyme solution with a biological enzyme concentration of 0.4mg / mL in step 3), each biological enzyme The dosage is 90U / g, and the detection is carried out after storage. The enzyme-treated tobacco stems are stored for 4 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com