Film coating machine with dust removal device

The technology of a dust removal device and a film coating machine is applied in the directions of devices, coatings, cleaning methods and utensils for coating liquid on the surface, which can solve the problems of inability to clean the dust thoroughly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following is further described in detail through specific implementation methods:

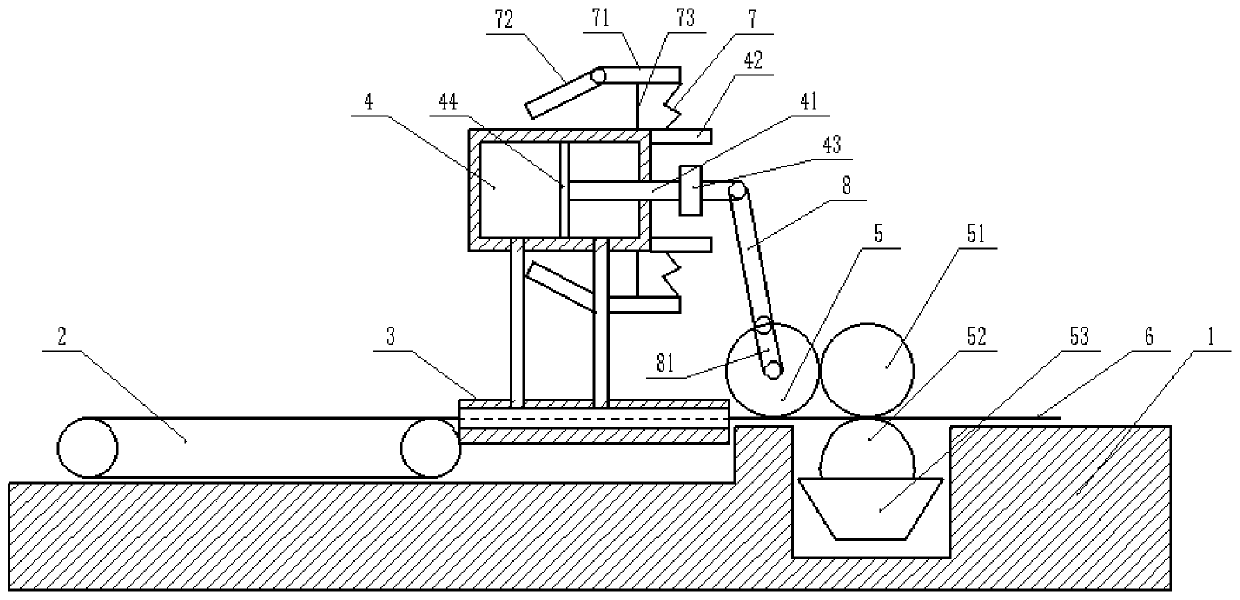

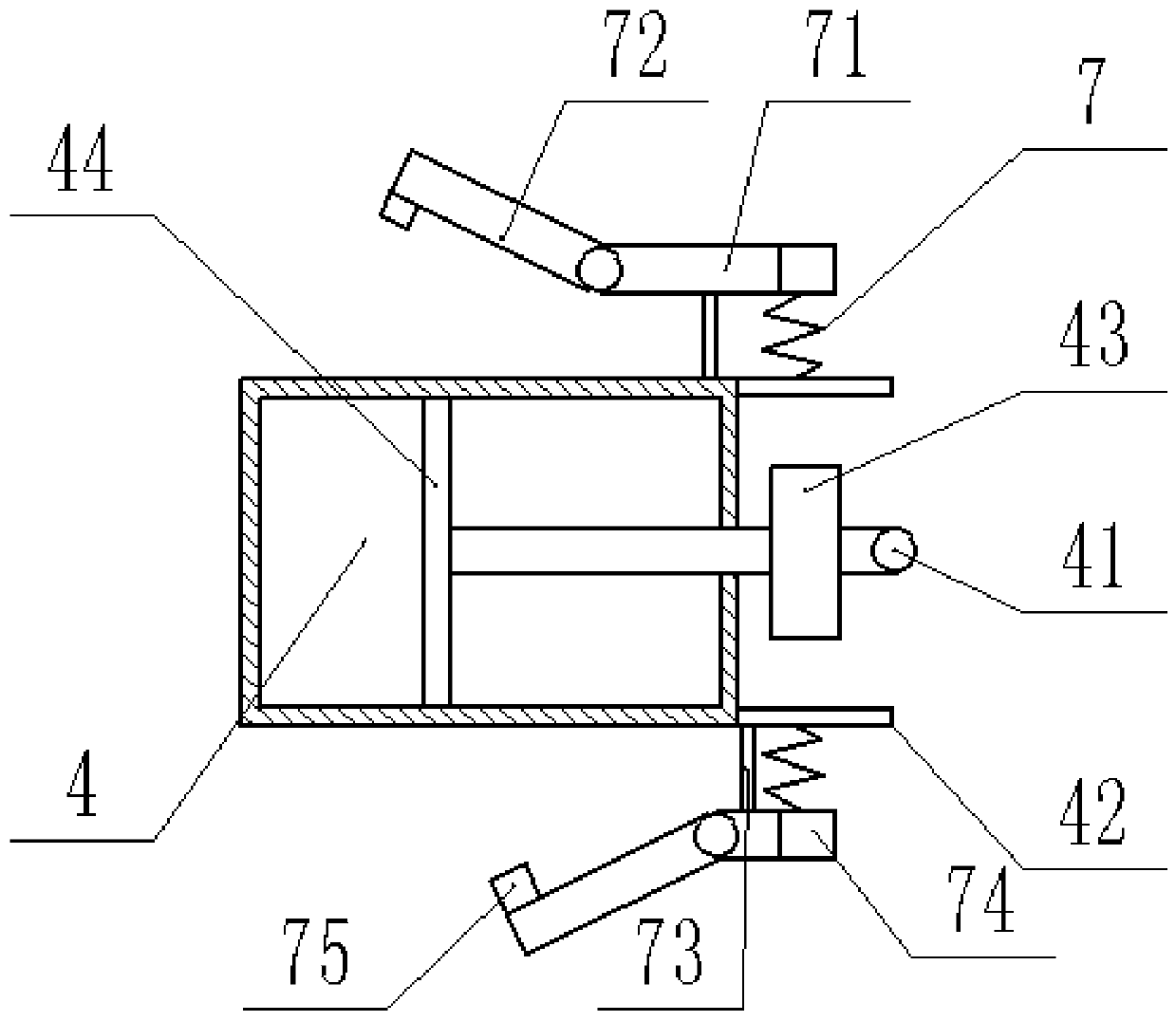

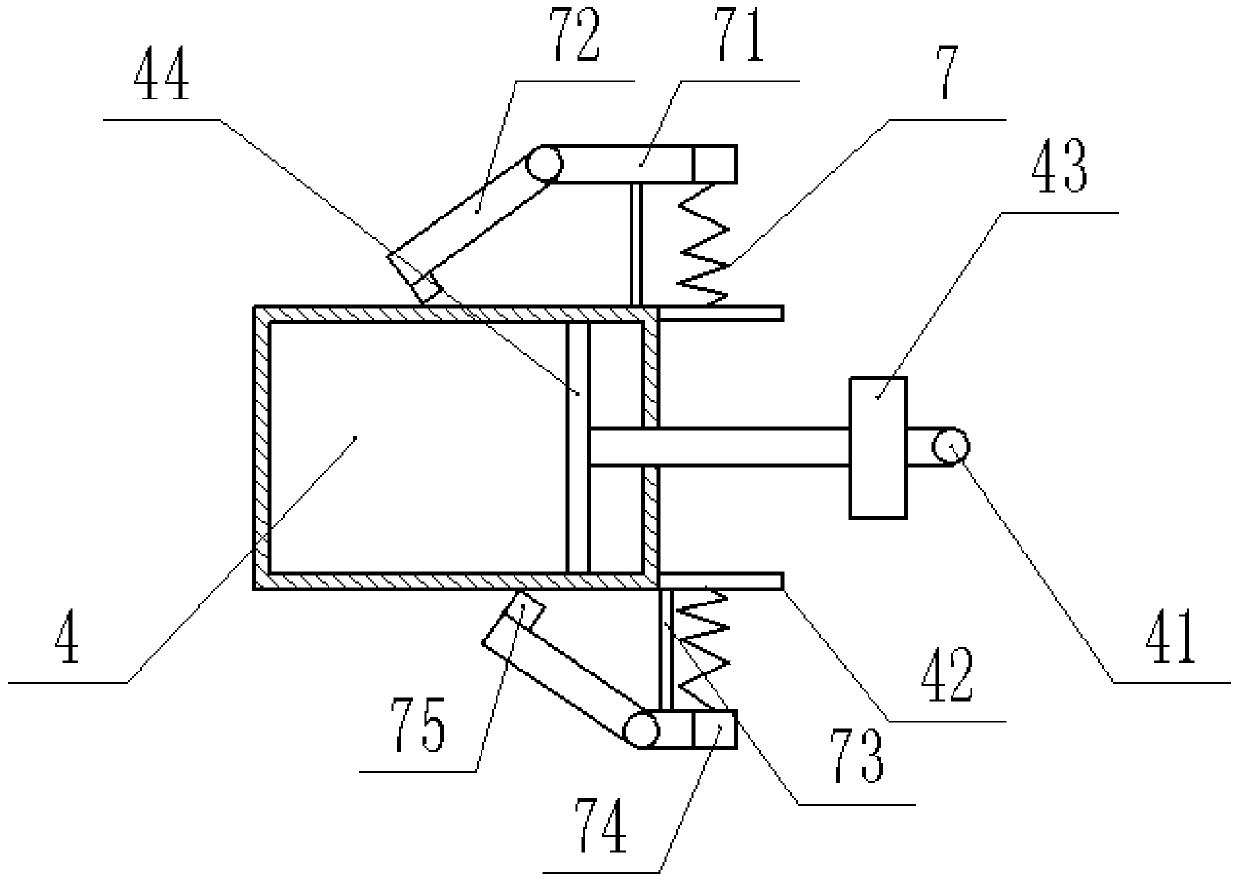

[0022] The reference signs in the drawings of the description include: frame 1, conveyor belt 2, dust removal chamber 3, piston barrel 4, piston rod 41, connecting plate 42, first magnet 43, piston 44, driving roller 5, first driven roller 51. The second driven roller 52, the coating material tank 53, the woven bag 6, the spring 7, the first pole 71, the second pole 72, the positioning pole 73, the second magnet 74, the bump 75, the first connecting rod Rod 8, second connecting rod 81.

[0023] Such as figure 1 As shown, a film coating machine with a dust removal device includes a frame 1, on which a conveyor belt 2, a dust removal chamber 3 and a rotating roller group are sequentially arranged from left to right, and the side wall of the dust removal chamber 3 is a double wall with a cavity. The layered structure includes an inner wall and an outer wall, the inner wall is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com