Pipe blind hole cleaning device

A technology for cleaning devices and blind holes, applied in heating devices, cleaning hollow objects, cleaning methods and utensils, etc., can solve the problems of accelerated impurity adsorption speed, incompleteness, and short cleaning effect, and achieves thorough cleaning and long use time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

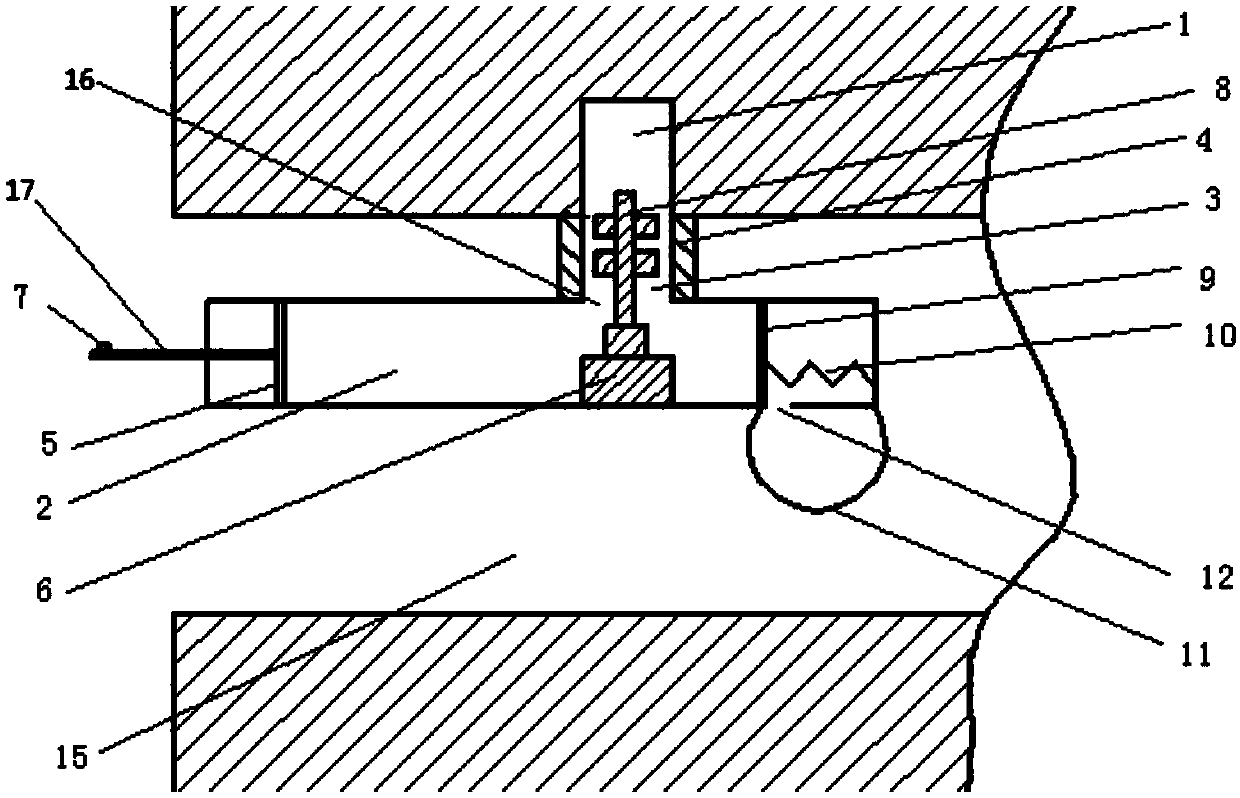

[0020] like figure 1 As stated, the blind hole cleaning device includes a housing 2, a cylinder body 3, a heating wire 4, a first piston 5, an automatic reciprocating cylinder 6, an automatic reciprocating cylinder switch device 7, a cleaning brush 8, a second piston 9, a spring 10 and Pocket 11. The casing 2 is cylindrical, and the casing 2 is provided with a first opening 16 and a second opening 12 . The barrel 3 is welded to communicate with the casing 2 at the first opening 16 . The heating wire 4 is detachably connected to the outer wall of the cylinder 3 by screws. The first piston 5 is slidingly fitted in the housing 2 , and the first piston 5 is coaxially welded with a handle 17 protruding from the housing 2 . The automatic reciprocating cylinder 6 is welded in the housing 2, and its output shaft is opposite to the opening of the cylinder body 3. Described cleaning brush 8 is connected on the output shaft of automatic reciprocating air cylinder 6 by screw thread. ...

Embodiment 2

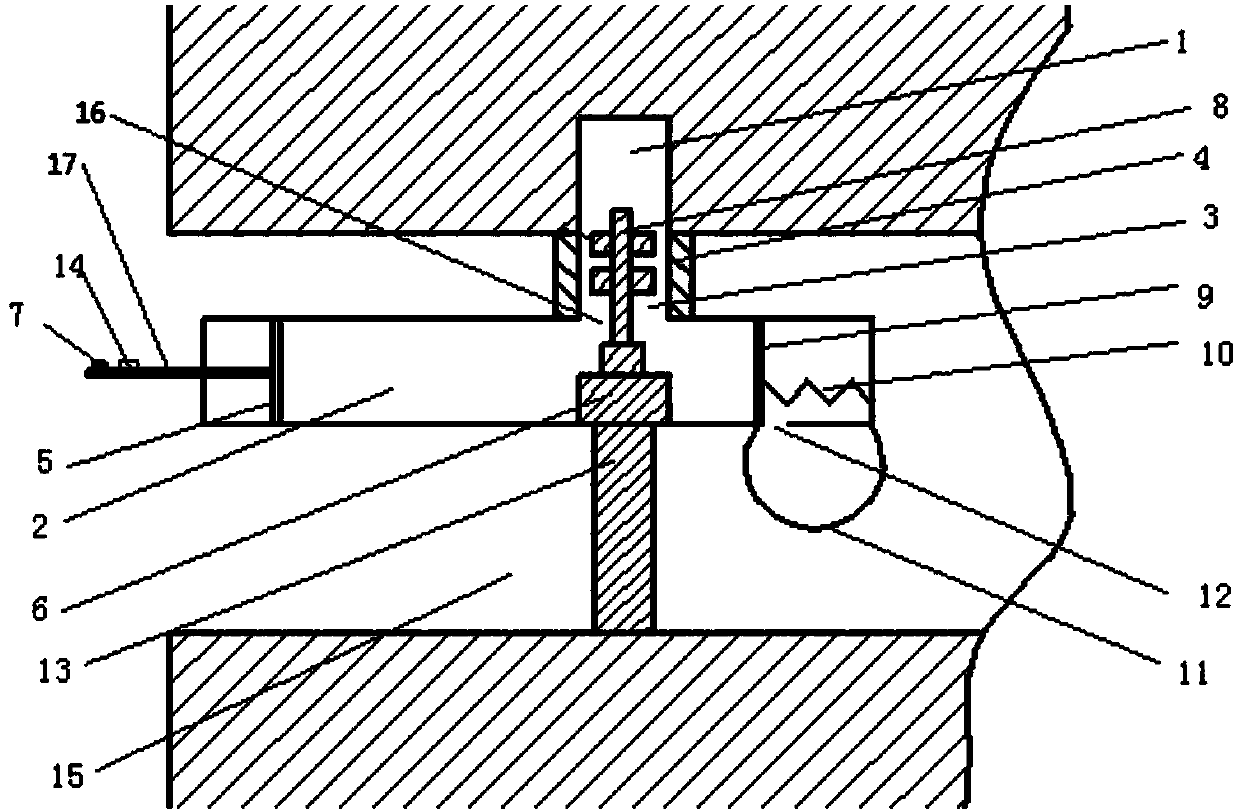

[0023] like figure 2 The structure schematic diagram of Embodiment 2 of the blind hole cleaning device, the difference between the blind hole cleaning device and the specific embodiment 1 is that this embodiment includes a support part 13 and a heating wire switch 14 . The support part 13 is installed on the outer wall of the shell 2 of the blind hole cleaning device, so that the blind hole cleaning device and the pipeline 15 are offset. The role of the support part 13 makes the cylinder body 3 and the wall of the blind hole 1 resist. When the first piston 5 is pushed, the pressure in the housing 2 increases. Since there is no gap between the cylinder body 3 and the blind hole 1, the solution No spillage for better cleaning environment. The heating wire switch 14 is installed on the handle 17, and is electrically connected with the heating wire 4. After the solution is drained, the heating wire switch 14 is pressed to make the heating wire 4 work, so that the heating wire 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com