Dust cleaning device for automatic welding platform

A fume purification and automatic welding technology, applied in the direction of dust removal, auxiliary equipment, welding equipment, etc., can solve problems affecting the operating environment and health, blurred vision, and toxic gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

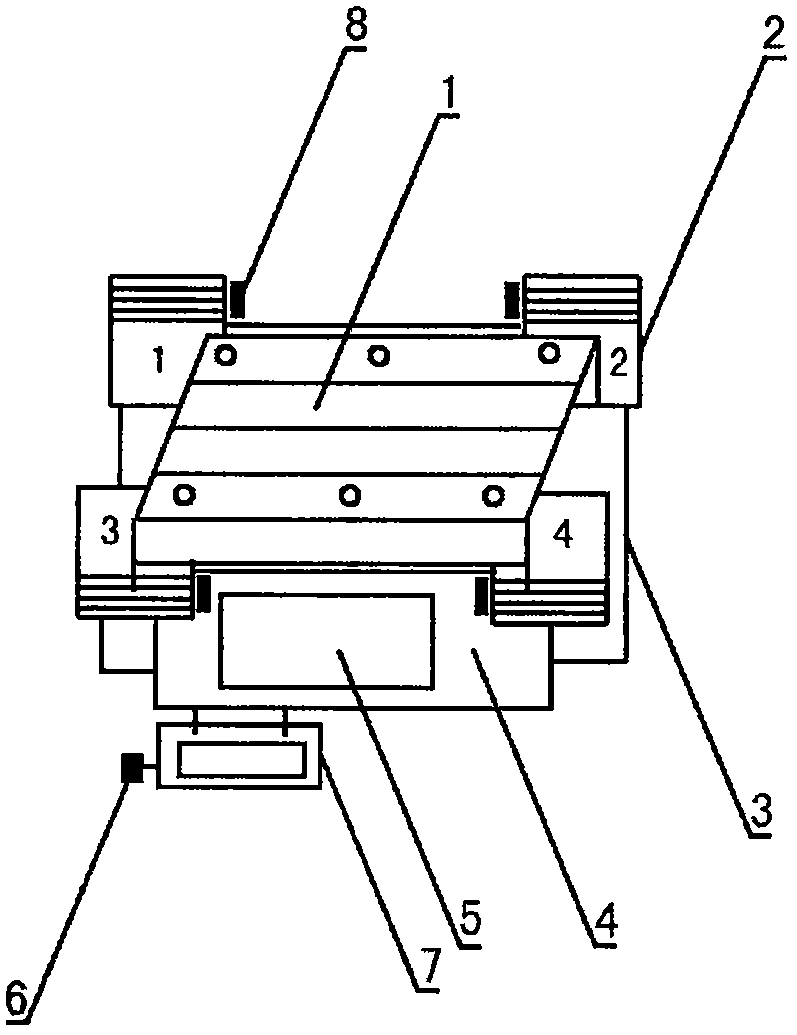

[0012] Embodiment: as shown in the accompanying drawing. A smoke and dust purification device for an automatic welding platform, comprising a welding platform (1), and a suction-type protective cover device (2) with a structure such as that arranged at the four corners of the platform (1) is in the form of a diagonal, and the upper end surface can adjust its coverage area, The bottom surface of the platform (1) is equipped with a hollow pipe device (3), a purification processor (4), and a display device (5). When in use, it is connected to an external power supply, and the smoke and dust generated during the welding process are collected and transported to the purification processor (3). Classify the internal consumption, and at the same time clearly display the dynamic data of the operation.

[0013] A smoke and dust purifying device for an automatic welding platform is provided with a warning device (6), and the information prompting mode is sound or LED light display.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com