Replacing equipment for bogie of subway train

A technology for replacing equipment and bogies, which is applied in the field of bogies, can solve the problems that affect the normal operation of the replacement, high investment costs, and large floor space, and achieve the effects of small floor space, low investment costs, and less equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

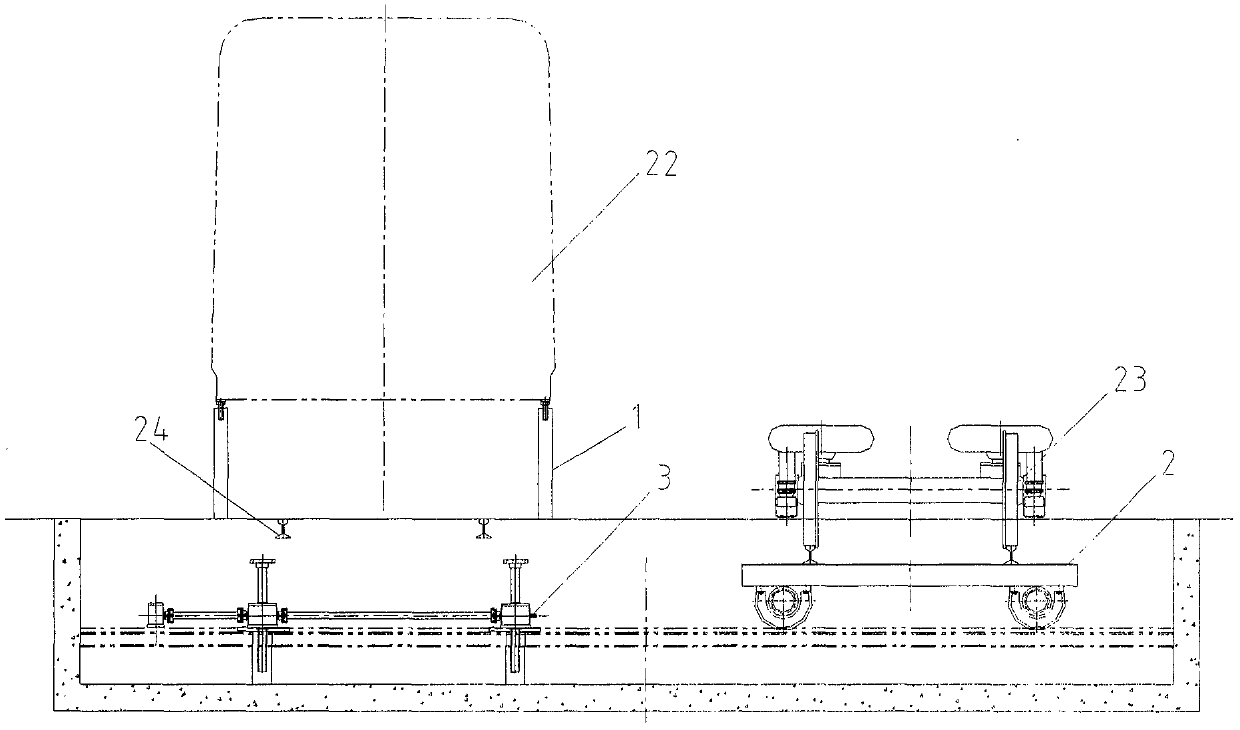

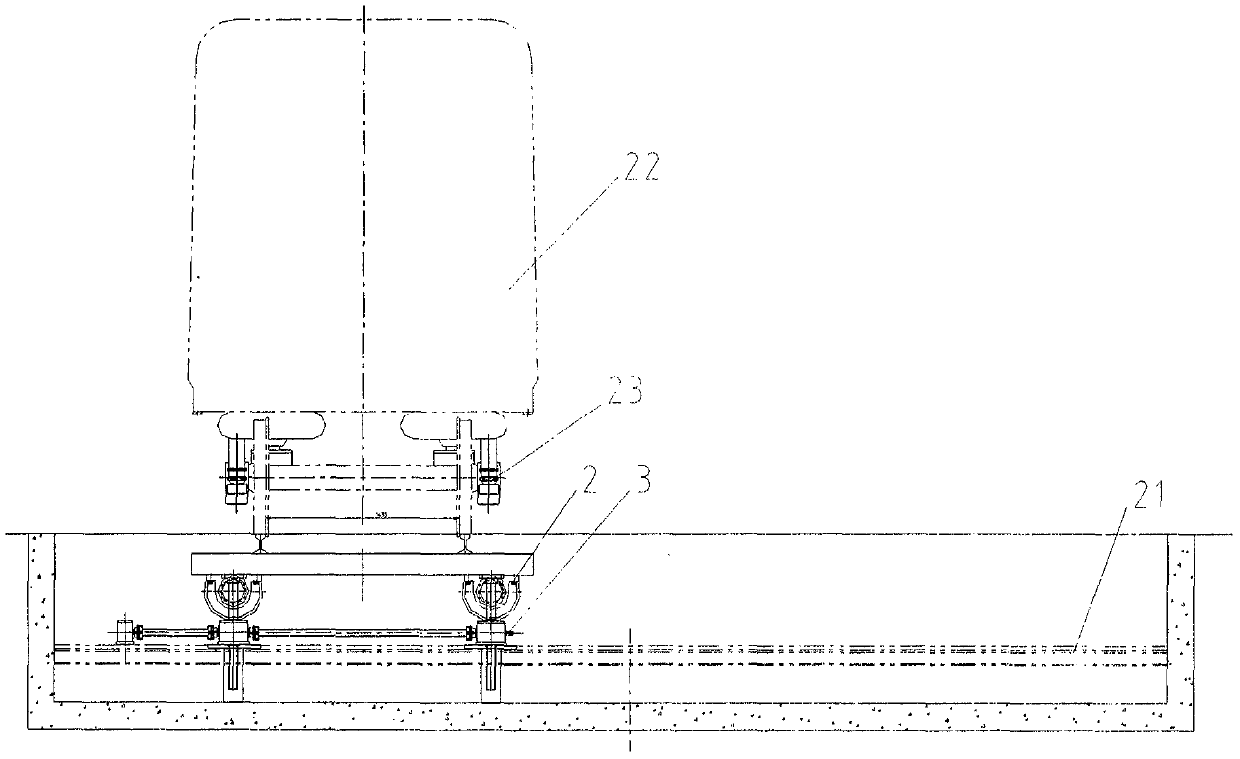

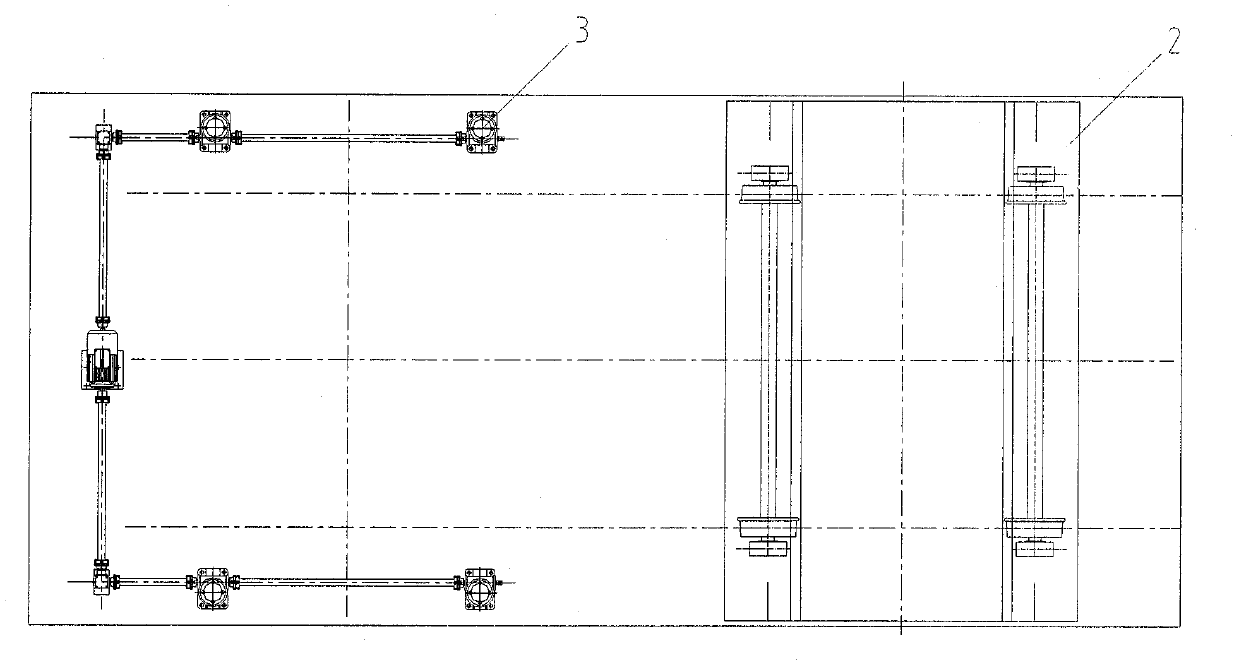

[0022] Attached below figure 1 , figure 2 , attached image 3 , attached Figure 4 , attached Figure 5 , attached Figure 6 , attached Figure 7 , attached Figure 8 , attached Figure 9 Embodiments will be described.

[0023] The subway train bogie replacement equipment consists of a support device 1, an electric flat car 2, a screw lift assembly 3, and a running track 21. The supporting device 1 is installed on the ground foundation at the same height as the ground track 24 of the subway train, under the both sides of the subway car body 22, the electric flat car 2 is arranged in the pit, and the electric flat car 2 is provided with a steel rail 13, as a subway A part of the ground track 24 of the train, a screw lift assembly 3 is set under the electric flat car 2, and the electric flat car 2 can be raised or lowered as required. When the electric flat car 2 is in a raised state, it can be used as a track for a subway train , when the electric flat car 2 is in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com