Asymmetry sliding groove lever type mechanical arm

A lever-type, asymmetric technology, applied in the field of automation, can solve the problems affecting the centering and clamping accuracy of the workpiece, workpiece collision, large swing range, etc., and achieve the effect of precise rotation accuracy, controllable speed and reasonable price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

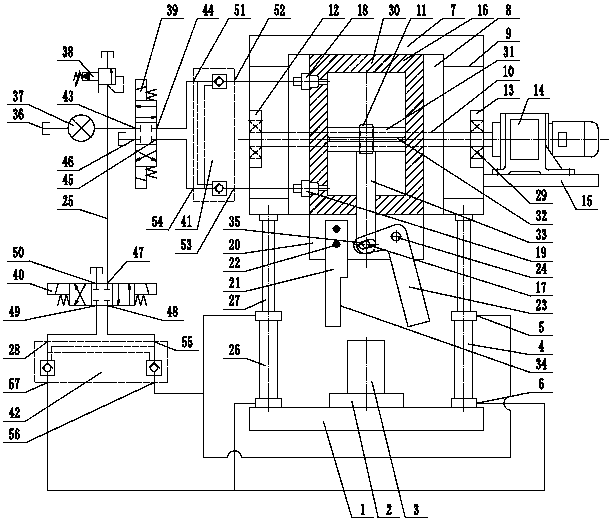

[0014] Such as figure 1As shown, an asymmetric chute lever type manipulator includes a frame 1, a workpiece support seat 2, a workpiece 3, a lifting cylinder 4, a first valve port 5, a second valve port 6, a lifting support 7, a horizontal sliding Seat 8, sliding guide rail 9, translation screw 10, screw nut 11, left screw support 12, right screw support 13, screw motor 14, motor support 15, support cylinder 16, latch 17, upper valve port 18 , lower valve port 19, finger support seat 20, fixed finger 21, fastening screw 22, inverted L-shaped movable finger 23, finger pin shaft 24, hydraulic drive system 25, the workpiece support seat 2 is fixed on the frame 1, The workpiece 3 is installed on the workpiece support s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com