Seven degree-of-freedom cooperative mechanical arm

A robotic arm and degree of freedom technology, applied in the field of robotics, can solve the problems of no redundant degrees of freedom, lack of flexibility, and lack of heat dissipation in the robotic arm, and achieve the effects of improving wiring safety, reasonable space utilization, and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

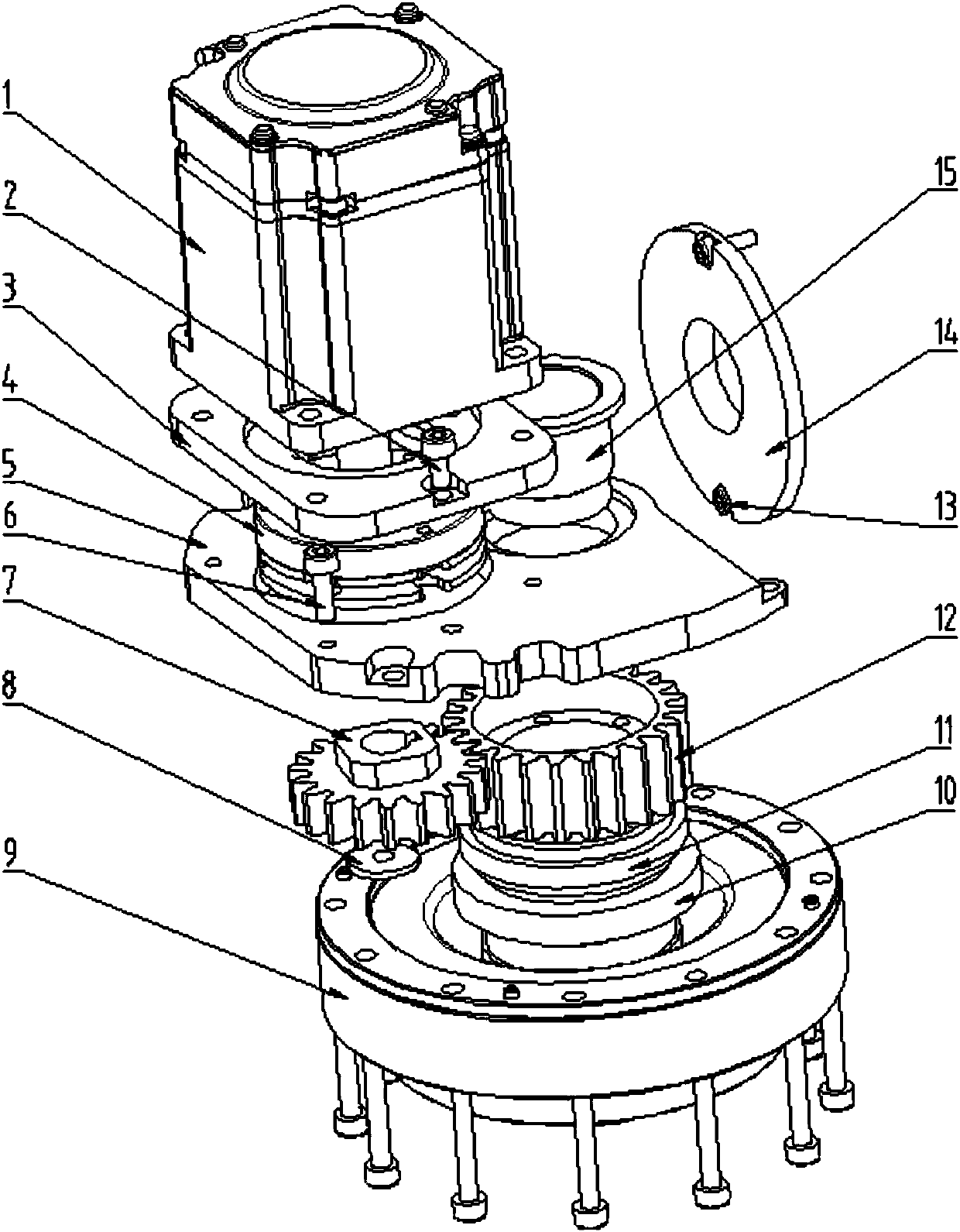

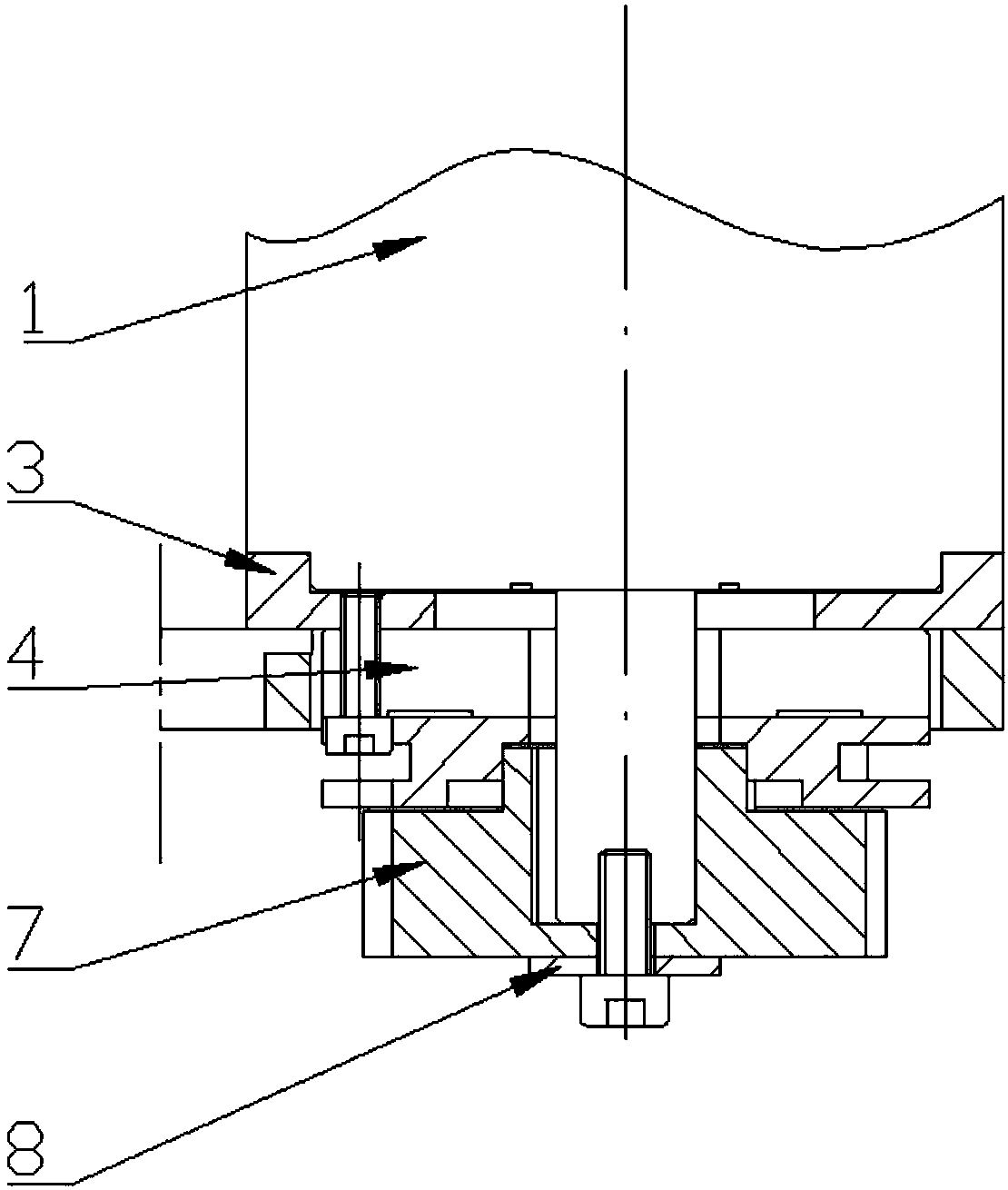

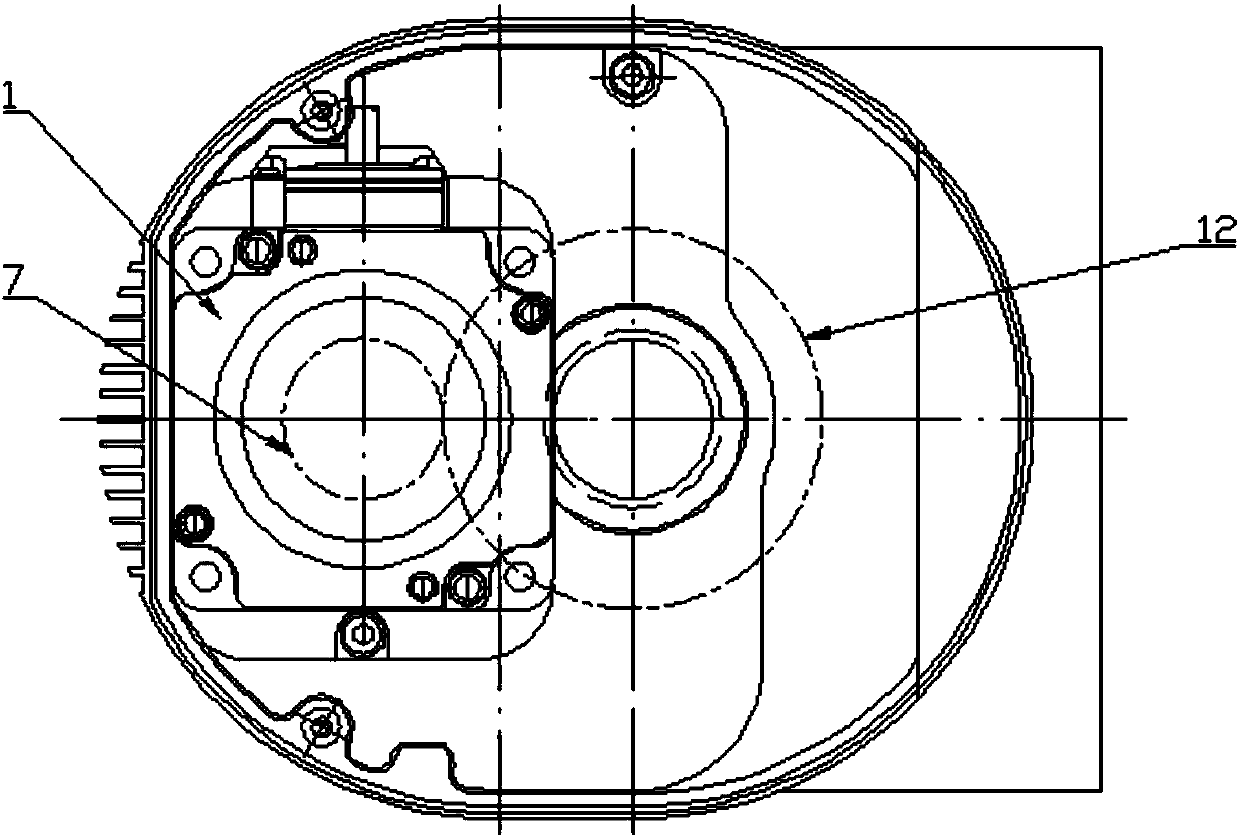

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific installation and working methods.

[0022] As shown in the accompanying drawings, a seven-degree-of-freedom cooperative robot arm of the present invention includes seven modular joints with the same structure, and the seven modular joints are respectively the first modular joint 19, the second modular joint 20, the second modular joint Three modular joints 22, the fourth modular joint 23, the fifth modular joint 25, the sixth modular joint 26 and the seventh modular joint 27, each modular joint all includes a housing 17, in the housing 17 An end cover 16 is installed on the top, and a sealing ring is preferably installed between the shell 17 and the end cover 16 .

[0023] A metal bracket 5 is fixed on the inner upper part of the housing, preferably on the metal bracket, there are a plurality of screw holes connecting the metal bracket and the housing in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com