Ground rail tram control system

A technology of control system and ground rail car, which is applied to the traction of motor vehicles, railway vehicles, and AC induction motors, etc. It can solve problems such as step-down transformer short-circuit current burnout, affecting normal production, and increasing equipment maintenance costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

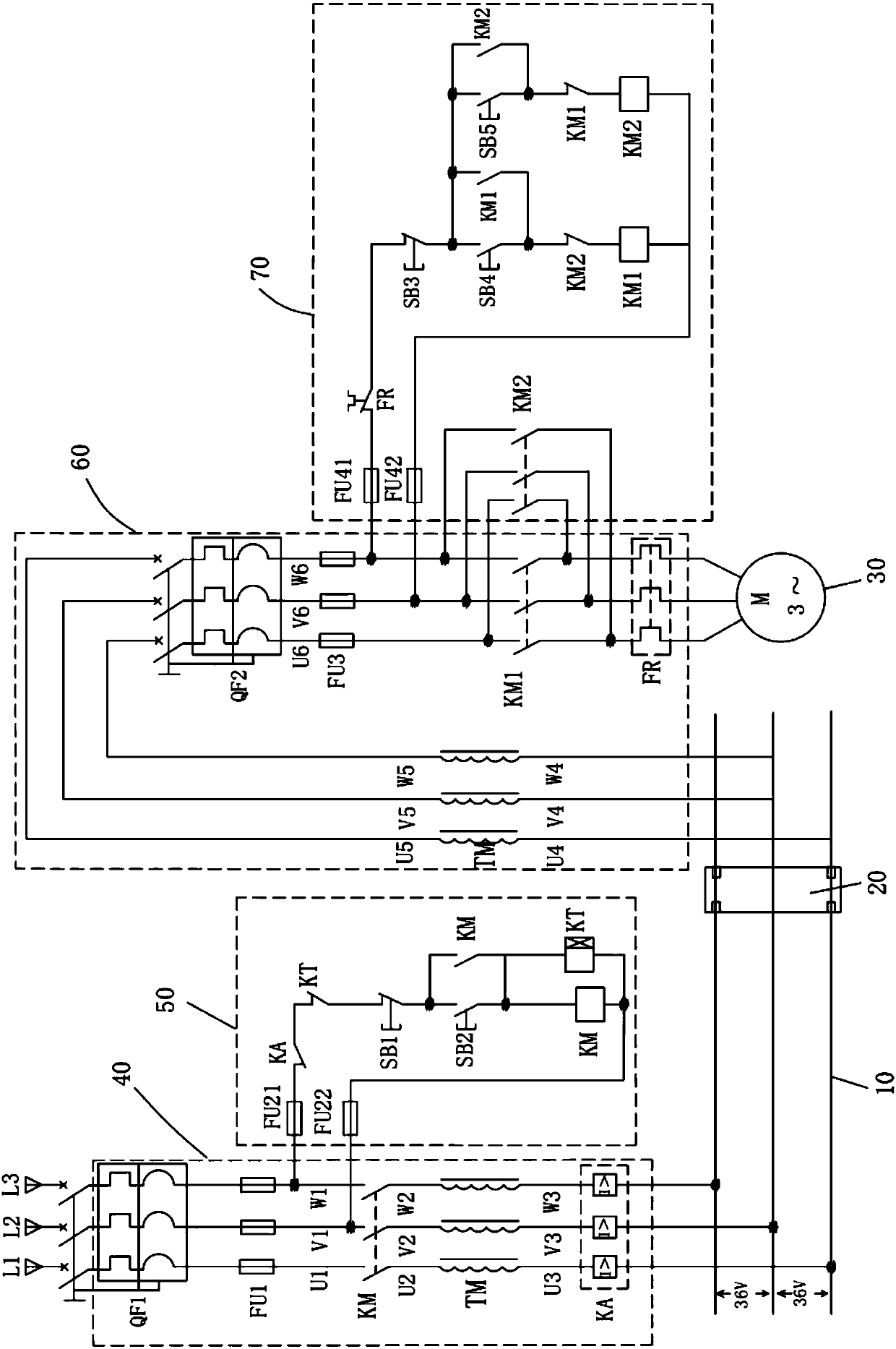

[0010] In order to more clearly describe the technical solutions of the embodiments of the present invention, the following will briefly introduce the drawings needed in the embodiments. Obviously, the drawings in the following description are some embodiments of the present invention. Ordinary technicians can obtain other drawings based on these drawings without creative work.

[0011] See figure 1 The embodiment of the present invention provides a ground rail tram control system, including ground rail 10, tram 20, drive motor 30, power supply circuit 40, power control circuit 50, flat car power supply circuit 60, flat car control circuit 70, ground The rail 10 is flat on the ground, the tram 20 moves on the ground rail, and the ground rail 10 is electrically connected to the tram 20. The driving motor 30 is installed on the tram 20 to drive the tram 20 to move. The power supply circuit 40 is connected to Between the industrial electricity and the ground rail 10, a step-down tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com