A fabrication method of deep submicron T-gate using conventional photolithography technology

A deep submicron, lithography technology, applied in the field of deep submicron T-type gate preparation, can solve the problems of inability to process deep submicron patterns, low electron beam lithography productivity, and limited production process line width, etc. Taking into account pattern size and production capacity, avoiding low production efficiency, and ensuring the effect of noise performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

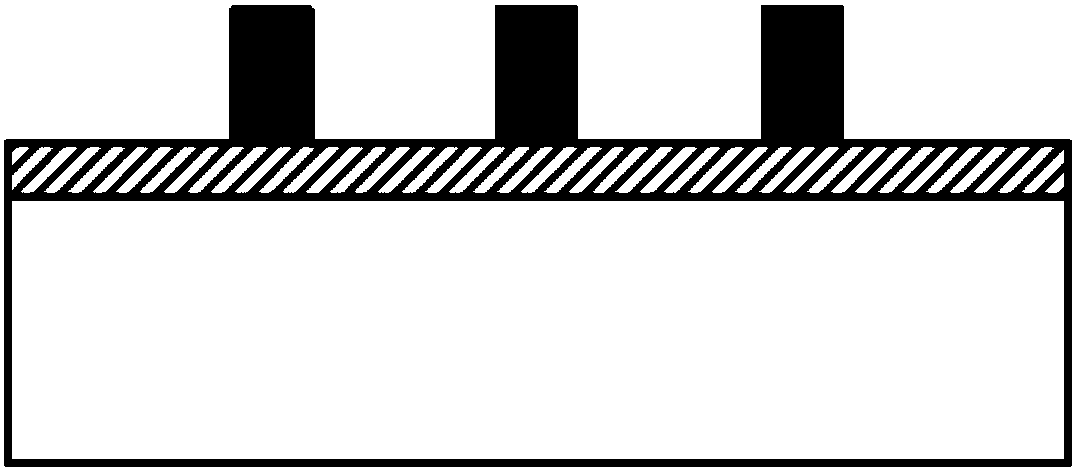

[0030] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

[0031] The preparation method of the deep submicron T-shaped gate using the conventional photolithography technology described in this embodiment mainly uses the traditional stepper photolithography machine, adopts the steps of glue coating, exposure and development to form patterns, and uses PECVD film deposition technology and ICP etching technology transfers deep sub-micron patterns to form gate feet, and then uses traditional photolithography to form gate caps to prepare deep sub-micron T-shaped gates. This method can take into account both gate length and production capacity. It includes the following steps;

[0032] Step 1: Carry out organic cleaning and surface oxide cleaning to increase the adhesion between the gate metal and the substrate surface, including: acetone ultrasonic cleaning for 5-7 minutes; isopropanol ultrasonic cleaning for 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com