A hollow guide rail foam strip stuffing device with double foam cans and its working method

A technology of hollow guide rails and foam strips, which is applied in the direction of transportation and packaging, elevators, conveyor objects, etc., can solve the problems of chamfering of foam strips, easy falling off, and low production efficiency, so as to achieve low labor intensity and ensure reliability , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with drawings and embodiments.

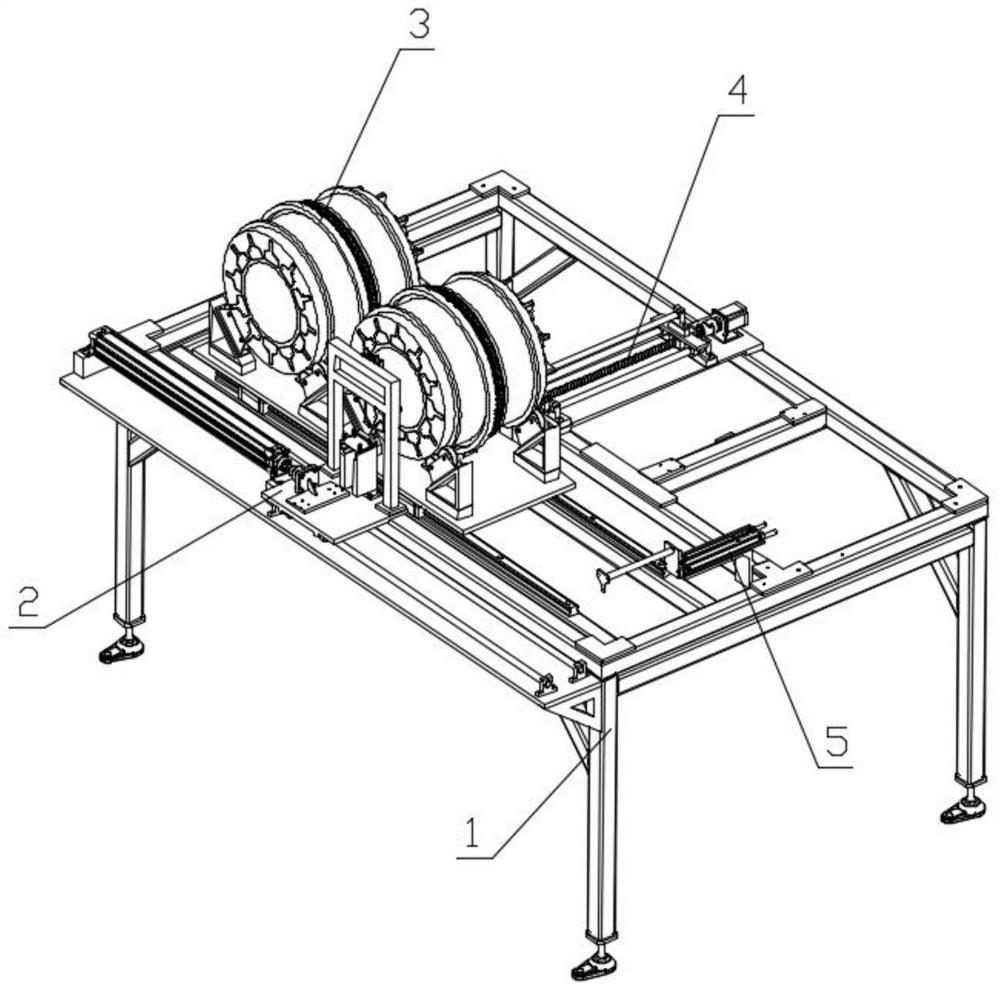

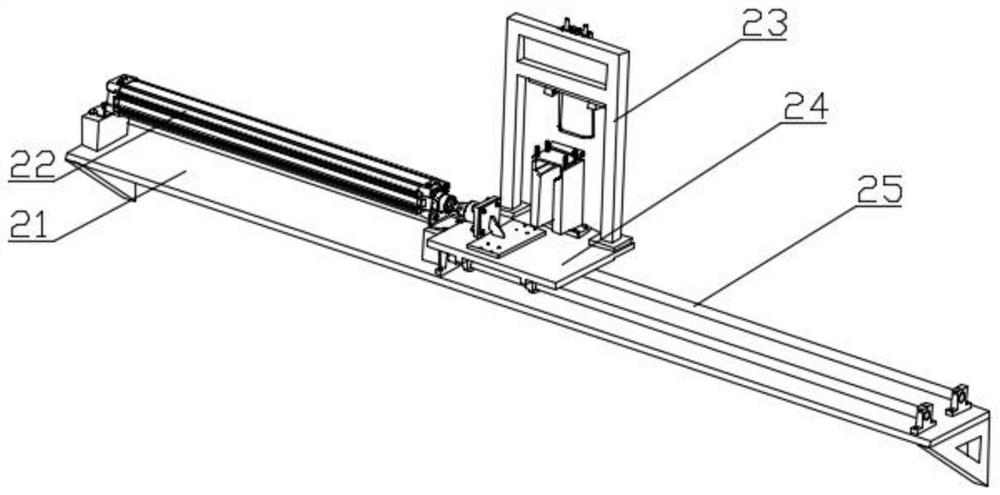

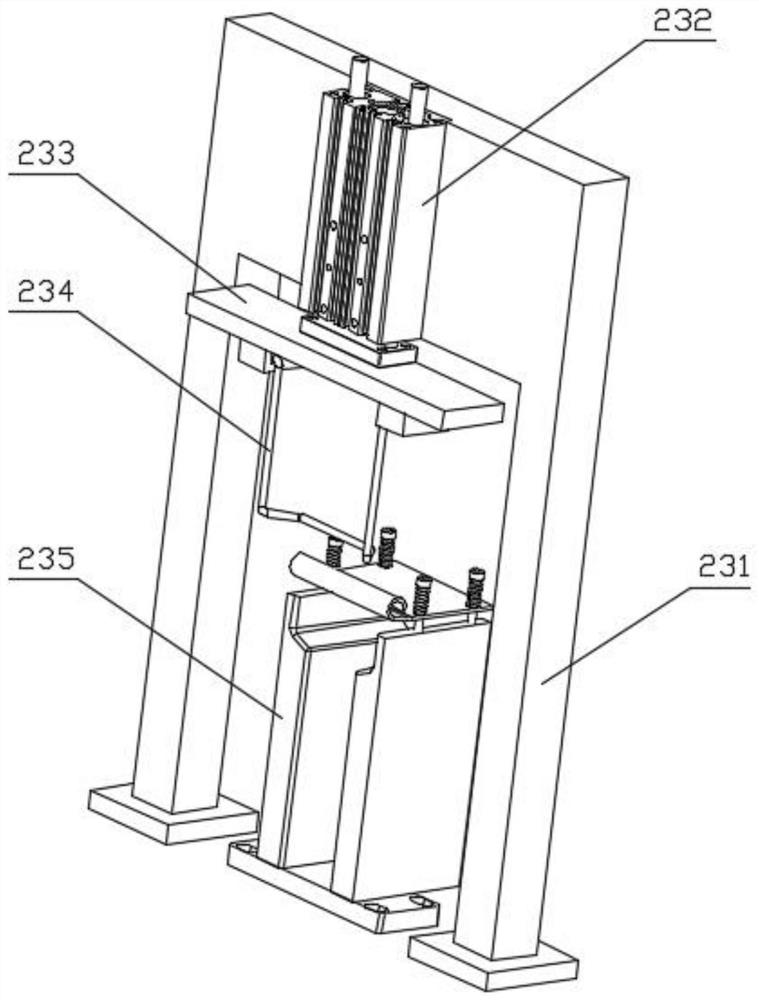

[0039] Such as figure 1 The foam strip stuffing device for the hollow elevator guide rail with double foam strips includes a bracket 1, a foam strip cutting and displacement part 2, a foam strip replenishing part 3, a foam strip stepping pushing part 4, and a foam strip pushing part 5. The mounting frame of the support 1 is welded by section bar, and its bottom plate is provided with adjustable height feet. The cutting and shifting part 2 is installed on the front side of the bracket 1, the foam bar replenishment part 3 is installed in the bracket 1 and is located at the rear side of the cutting and shifting part 2, and the step pushing part 4 is installed in the bracket 1 and Located on the rear side of the foam strip replenishing part 3 , the foam strip pushing part 5 is located on the side where the bracket 1 is installed, and is perpendicular to the foam strip cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com