Roller bearing loading device and loading device

A roller bearing and feeding technology, which is applied in the field of bearing manufacturing, can solve the problems of roller structure wear and roller surface damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

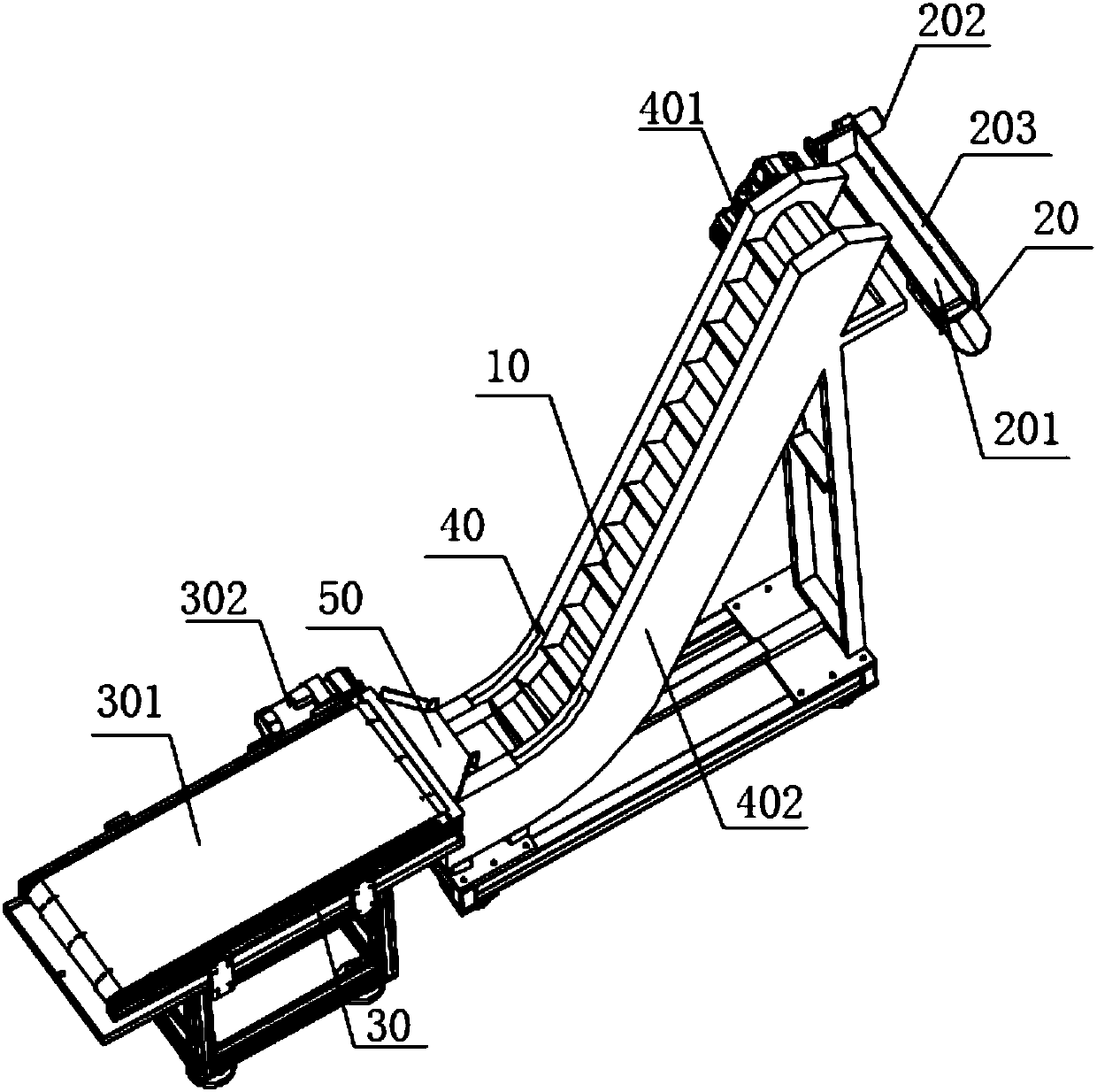

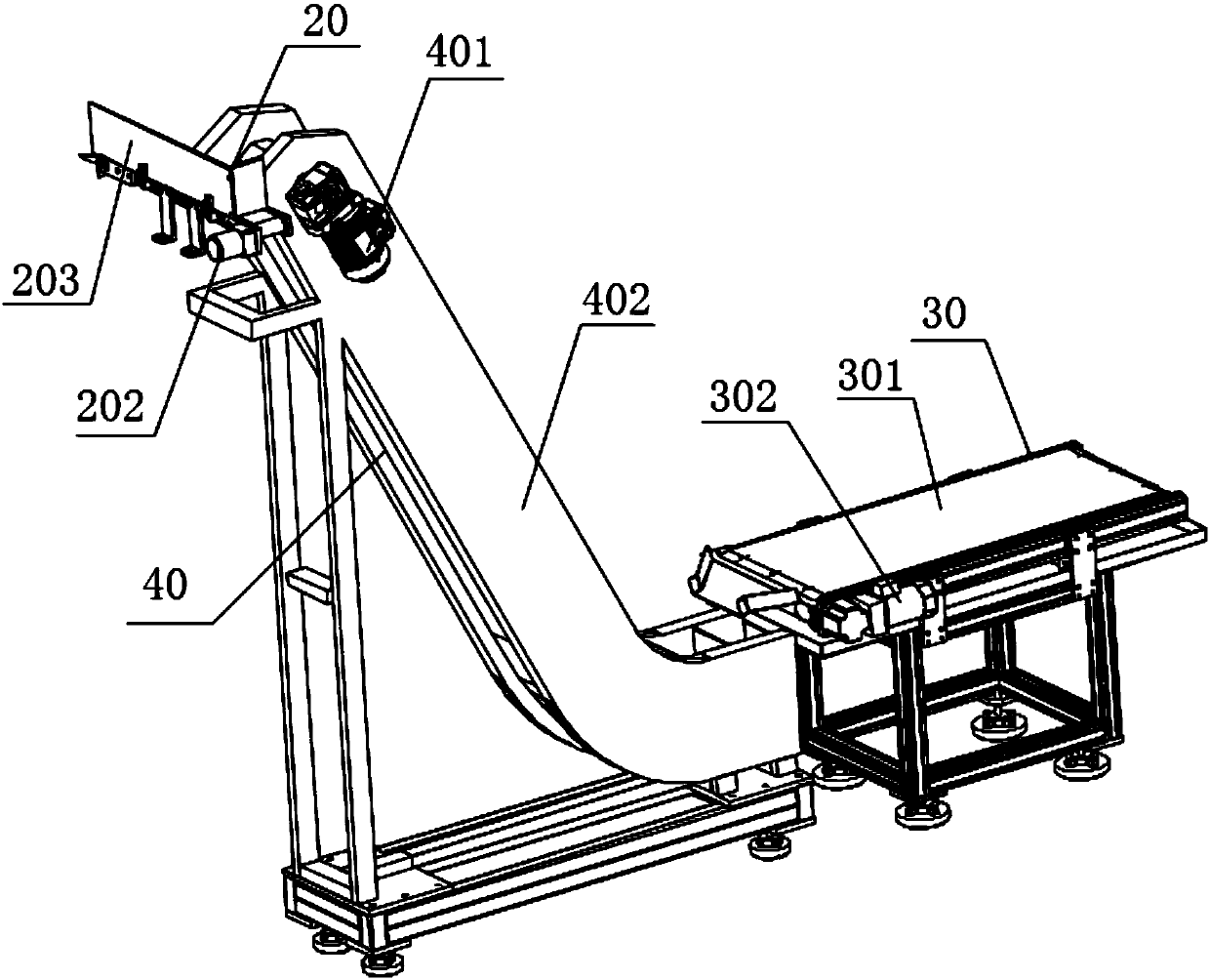

[0042] like Figure 1-3 As shown, the roller bearing feeding device provided in this embodiment includes a conveying module and a material handling module 20; The module 20 is used to arrange the roller bearings; the conveying module is provided with a partition, and one end of the partition is connected to the material handling module 20; the partition includes a plurality of lattice structures 10, and the plurality of lattice structures 10 are sequentially arranged along the length direction of the partition , The lattice structure 10 is used to place the roller bearing.

[0043] Specifically, the roller bearing feeding device includes a conveying module and a material handling module 20, the conveying module is the part that conveys the roller bearing, the material handling module 20 is connected to the conveying end of the conveying module, and the roller bearing is conveyed through the conveying module To the sorting module 20, through the sorting module 20, the roller b...

Embodiment 2

[0082] This embodiment also provides a feeding device, including the above-mentioned roller bearing feeding device.

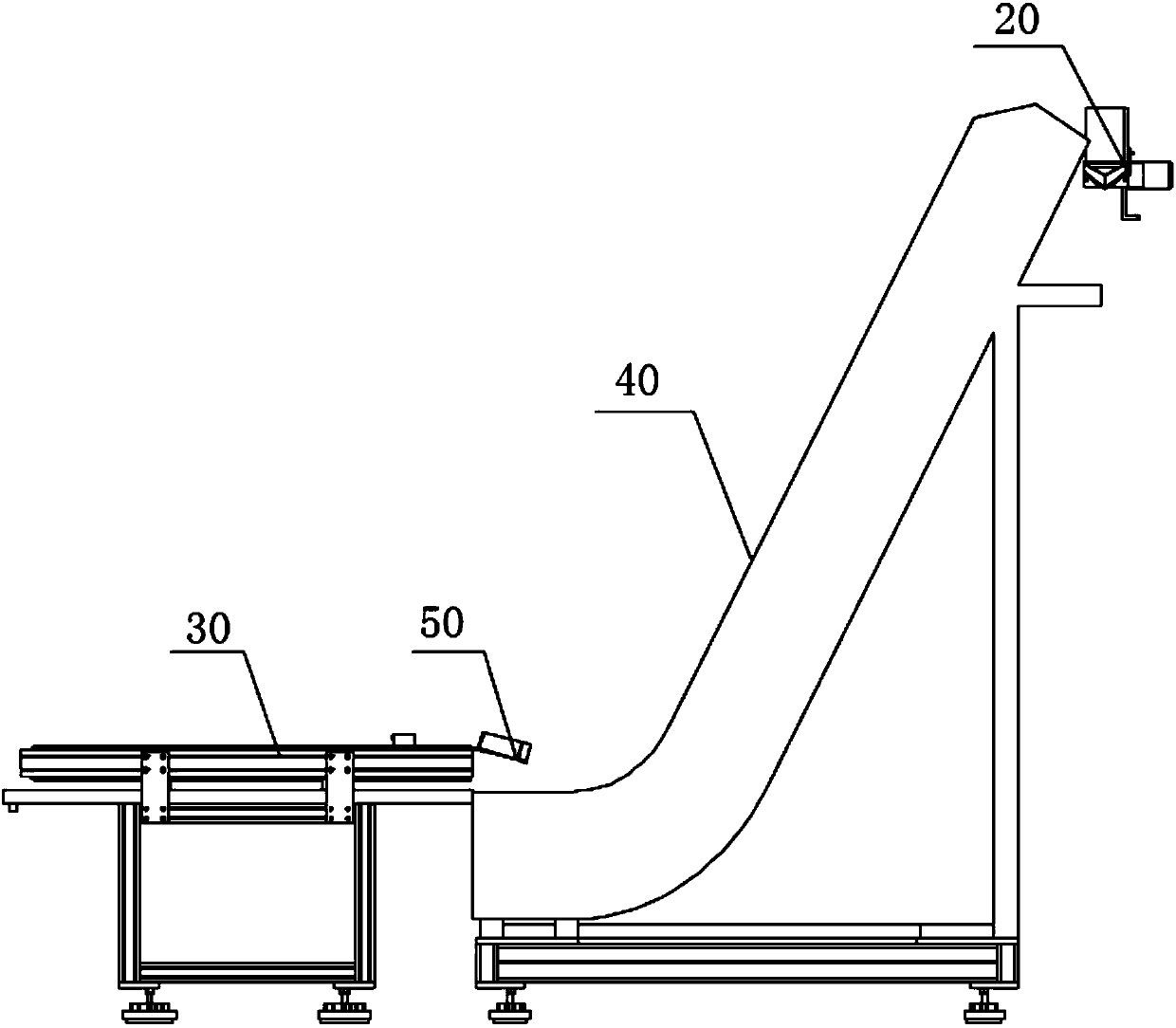

[0083] Specifically, the horizontal transfer of the rollers is realized by the first delivery module 30 arranged in the horizontal direction, and the transfer of the rollers in the height direction is realized by the second delivery module 40 arranged in the height direction; when transferring in the height direction, A plurality of lattice structures 10 are also arranged on the second conveying part, so as to separate the plurality of roller bearings as much as possible, reducing the probability of the roller bearings being damaged during the transmission process; at the same time, forming a The support function improves the problem that the rollers are easy to fall when they are transmitted along the height; in addition, the setting of the lattice structure 10 reduces the abrasion of the roller bearings, realizes the non-destructive transmission of the rollers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com