A micro-expansion grouting material for tunnel lining vault with mold grouting

A technology of micro-expansion and grouting material, which is applied in the field of concrete materials, can solve the problems of insufficient compatibility and combination, hollowing out of tunnel vaults, easy shrinkage and deformation, etc., achieve good fluidity and pumpability, and improve The overall bearing capacity and the effect of improving the humidity field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to enable those of ordinary skill in the art to fully understand the technical solutions and beneficial effects of the present invention, further descriptions are given below in conjunction with specific embodiments.

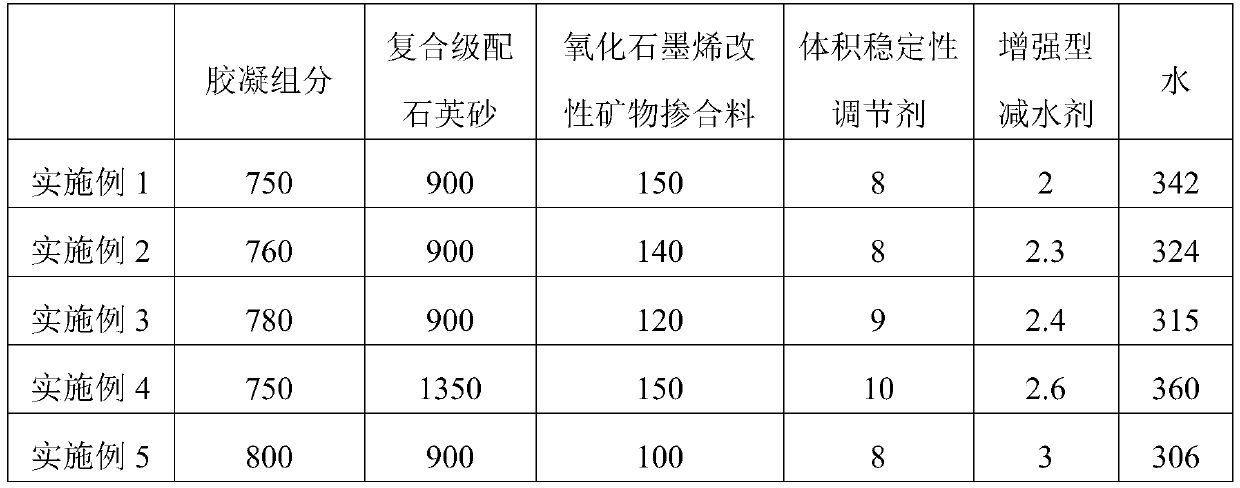

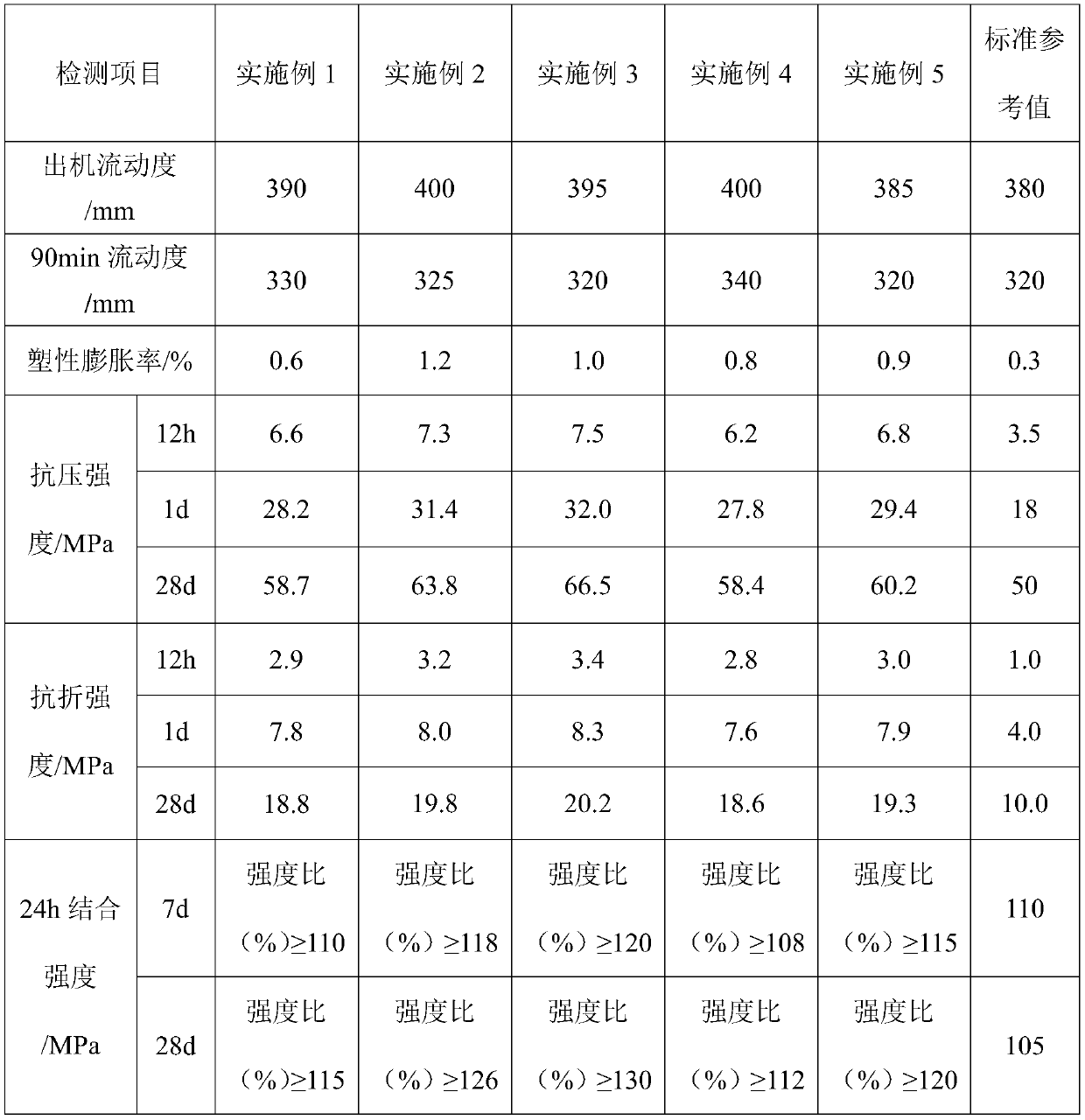

[0015] A micro-expansion grouting material for grouting with a mold on the vault of tunnel lining. It is made by mixing the following raw materials in parts by weight: 750-800 parts of gelling component, 900-1350 parts of composite grade quartz sand , Graphene oxide modified mineral admixture 100 to 150 parts, volume stability regulator 8 to 10 parts, enhanced water reducing agent 2 to 3 parts, water to material ratio 0.16 to 0.19. The cementitious component is mixed with 42.5 grade ordinary Portland cement and 42.5 grade sulphoaluminate cement at a mass ratio of 19:1, mixed with triethanolamine equivalent to 0.05% of the total mass of the two cements, and ground to a ratio The surface area is 400~500m 2 / kg. The composite graded quartz sand used i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com