Concrete bridge crack reinforcement device

A reinforcement device and concrete technology, which is applied in the direction of bridge reinforcement, bridge, bridge maintenance, etc., can solve the problems of low tensile strength, formwork, support is not fixed firmly, and water evaporates too fast, so as to achieve good reinforcement performance and increase the scope of use , the effect of its own firm structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

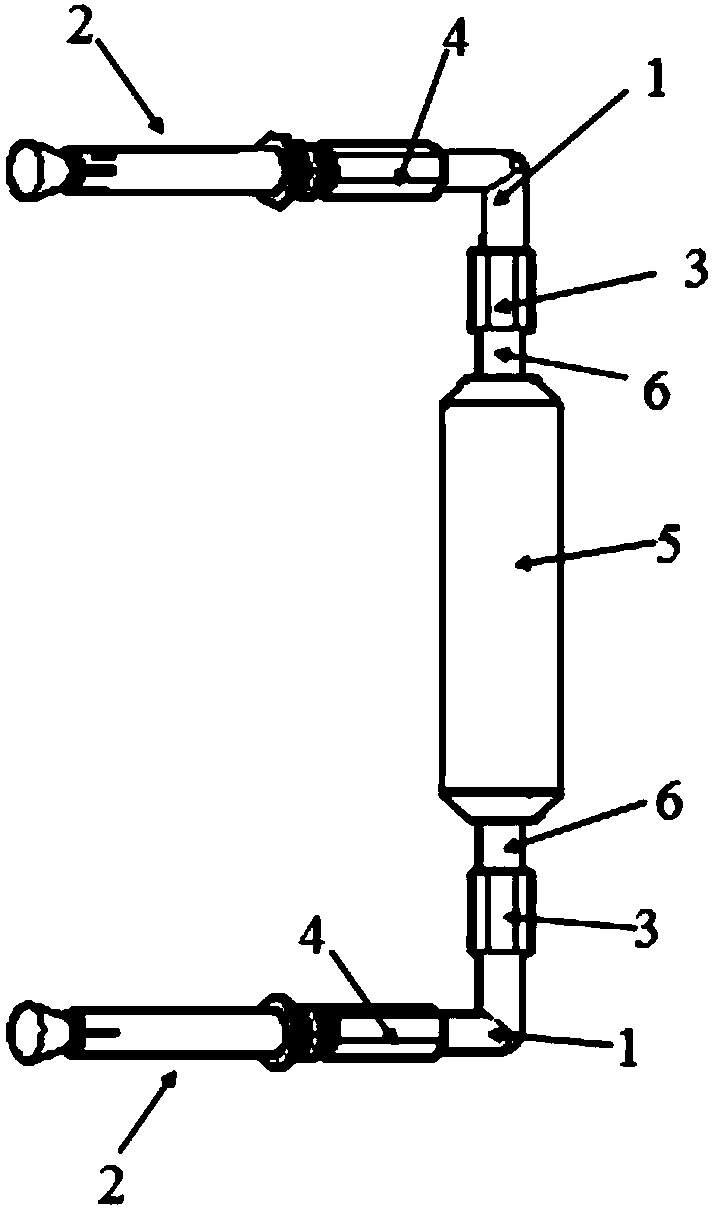

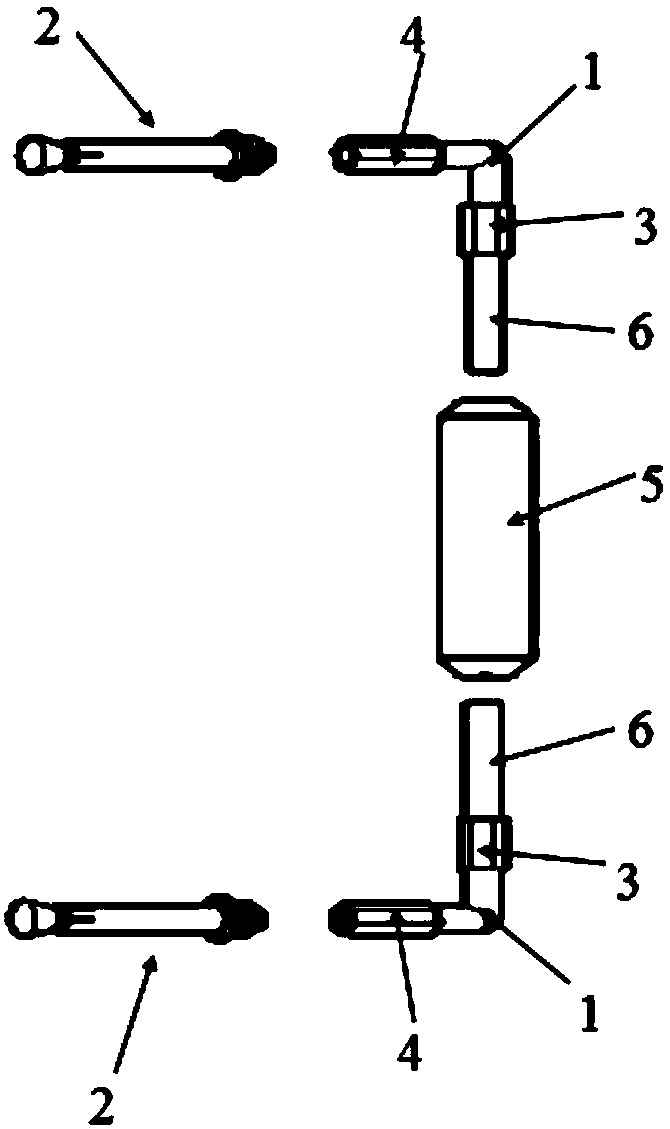

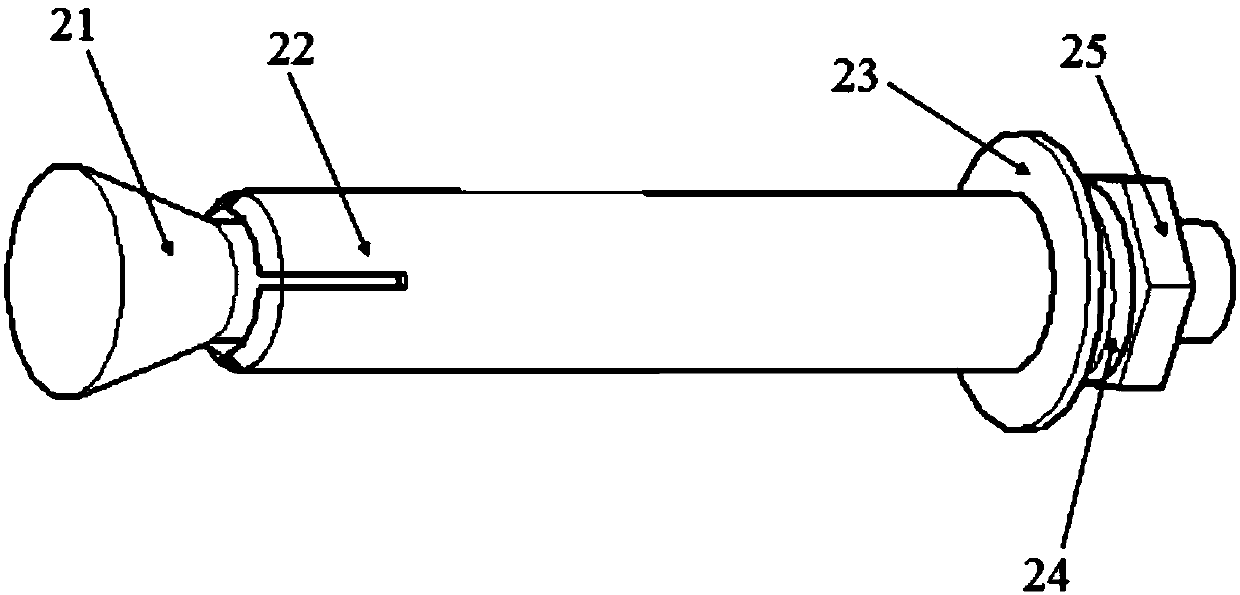

[0025] Embodiment 1: as figure 1 and figure 2 It shows that a reinforcement device for concrete bridge cracks according to the present invention includes a fixed body, a curved rod 1 and a mounting piece, the curved rod 1 is arranged at both ends of the fixed body, and the fixed body is respectively connected to one end of the curved rod 1 through the first nut 3 , the other end of the bent rod 1 is connected with the mounting part 2 through the second nut 4 . Such as image 3 As shown, the bending rod is bent at 90°. Such as Figure 4 As shown, the two ends of the bent rod contain key grooves, which allow positioning and rotation of the first nut 3 and the second nut 4, and the key grooves are used to limit the axial displacement of the nuts. The mounting part is composed of a bolt 21, an expansion tube 22, a hex nut 23, a spring washer 24 and a flat washer 25 connected in sequence, and forms a detachable connection with the second nut 4. In this embodiment, the mounting...

Embodiment 2

[0027] Embodiment 2: as Figure 8 As shown, when the crack of the bridge is large, the fixing device fixes the anchor rod 8 in the middle of the cylindrical casing 5; the anchor rod and the cylindrical casing are connected by detachable threads, and the other end of the anchor rod extends to the bottom of the crack. The anchor rod can play a better role in supporting the crack.

Embodiment 3

[0028] Embodiment 3: as Figure 8 The shown anchor rod is provided with reinforcing ribs 9, and the reinforcing ribs 9 are welded on the anchor rod 8. The reinforcing ribs are divided into transverse ribs and longitudinal ribs. The anchor rods are parallel, and the longitudinal ribs are arranged equidistantly. When the cracks are large, the device of the present invention adds anchor rods and reinforcing ribs, and pours concrete into the cracks, so that the cracks can be further repaired and the service life of the bridge can be increased.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap