Oil way arranging structure of engine piston cooling nozzle

A piston cooling nozzle and layout structure technology, which is applied to the cooling of the engine, engine components, machines/engines, etc., can solve the problems of complex cylinder structure, difficult production and processing, etc., to simplify the cylinder structure, simplify casting, and ensure production Effects on Efficiency and Yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

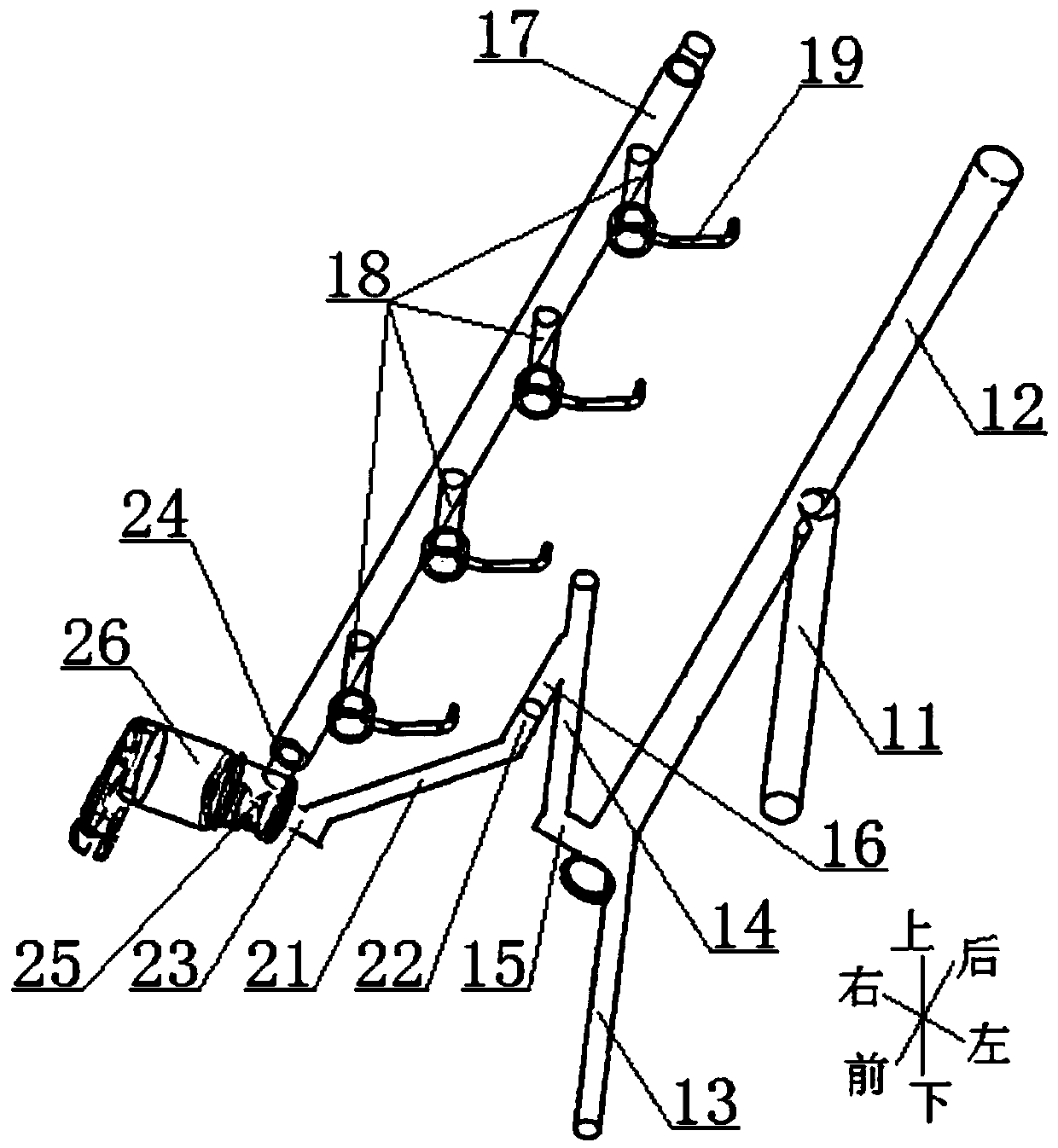

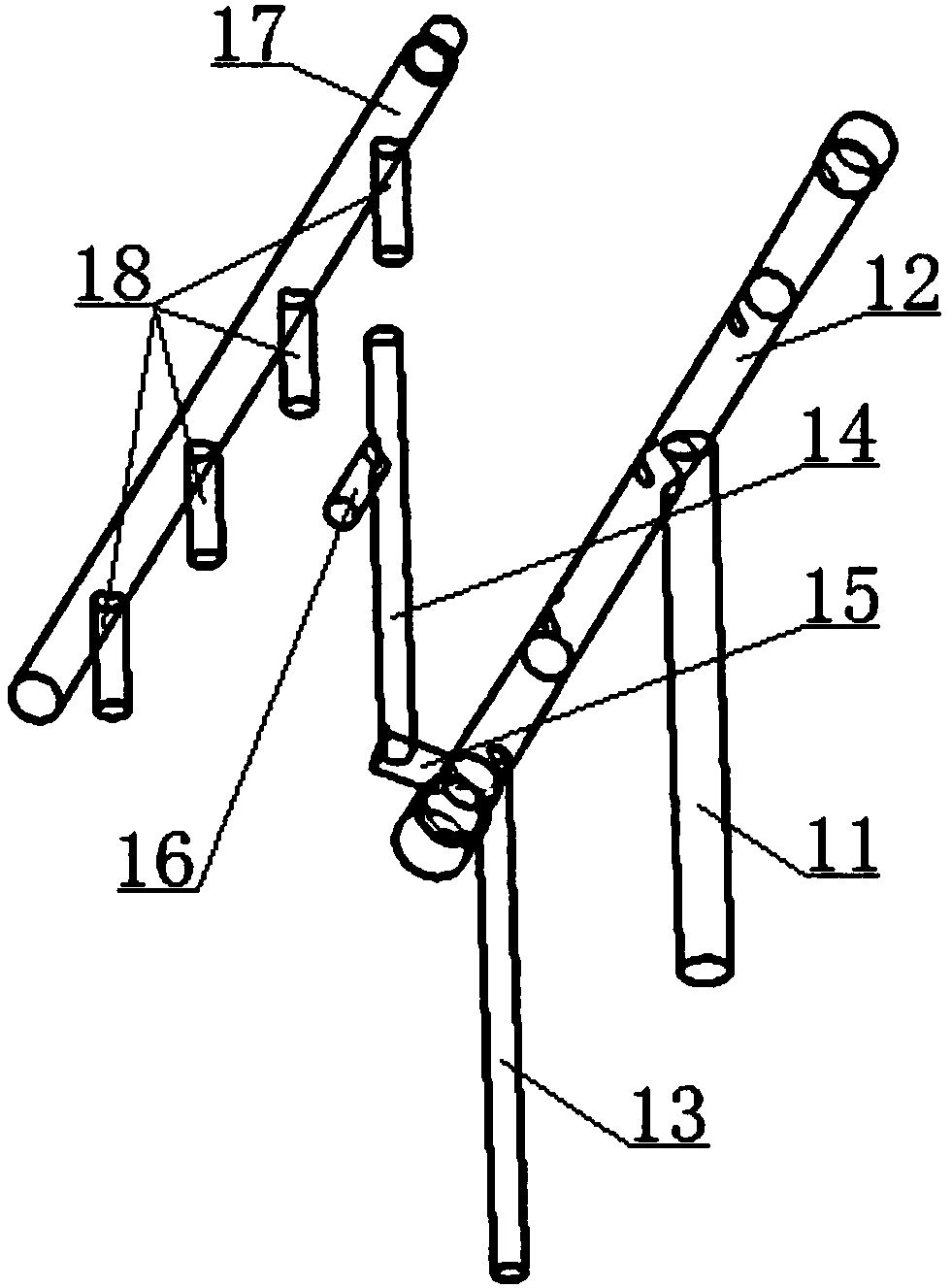

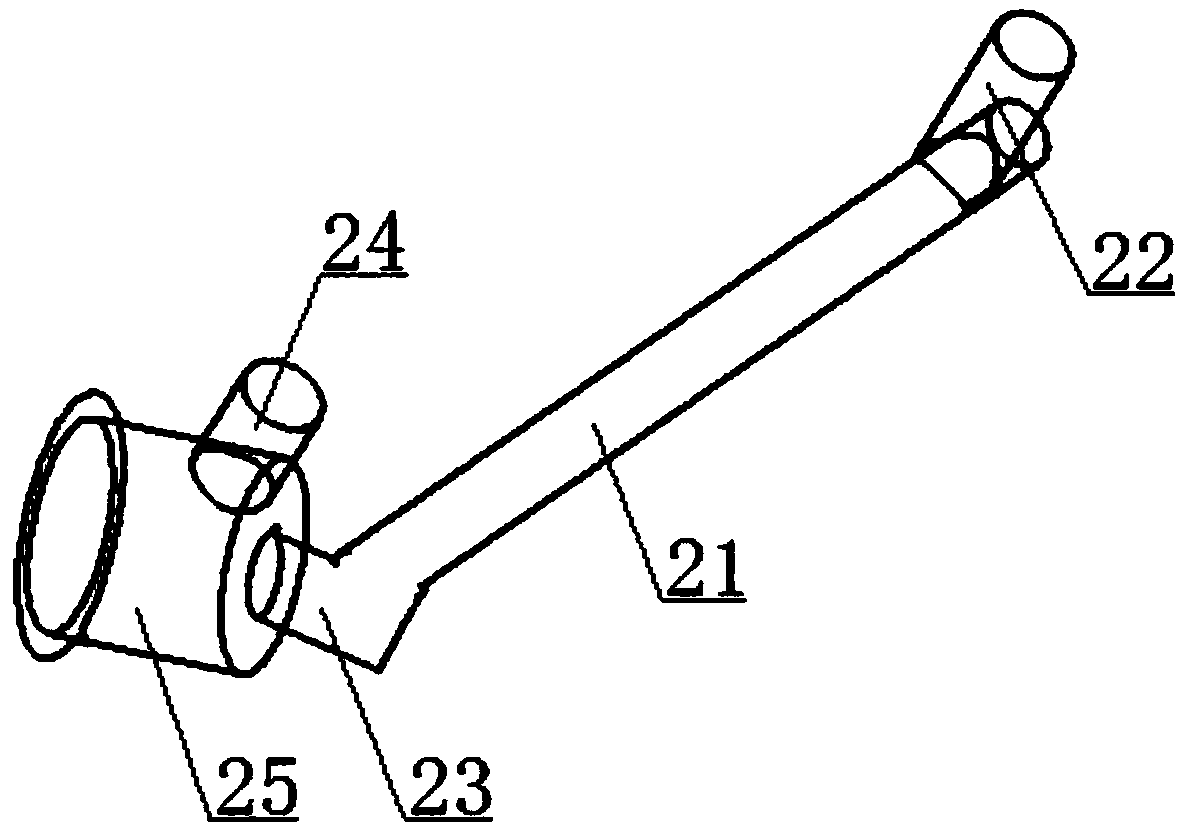

[0021] see Figure 1 to Figure 3 The shown oil circuit layout structure of an engine piston cooling nozzle includes cylinder block oil inlet passage 11 arranged in the cylinder body, intake side transverse main oil passage 12, cylinder head oil inlet passage 14, exhaust side transverse main oil passage The oil passage 17 is characterized in that: it also includes a front end oil passage arranged in the front cover and a solenoid valve mounting hole 25 arranged on the front end oil passage; the oil inlet passage 11 of the cylinder block and the oil inlet passage 14 of the cylinder head are all vertical Arranged directly on the air intake side of the cylinder body, the upper end of the oil inlet passage 11 of the cylinder body is connected with the transverse main oil passage 12 of the intake side, and the lower end of the oil inlet passage 14 of the cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com