Hydraulic oblique push type offshore wind turbine installation system

An offshore wind turbine and installation system technology, which is applied in the assembly of wind turbines, the transportation of wind turbines, the configuration of installation/support of wind turbines, etc. The effect of optimizing installation steps, improving accuracy and improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

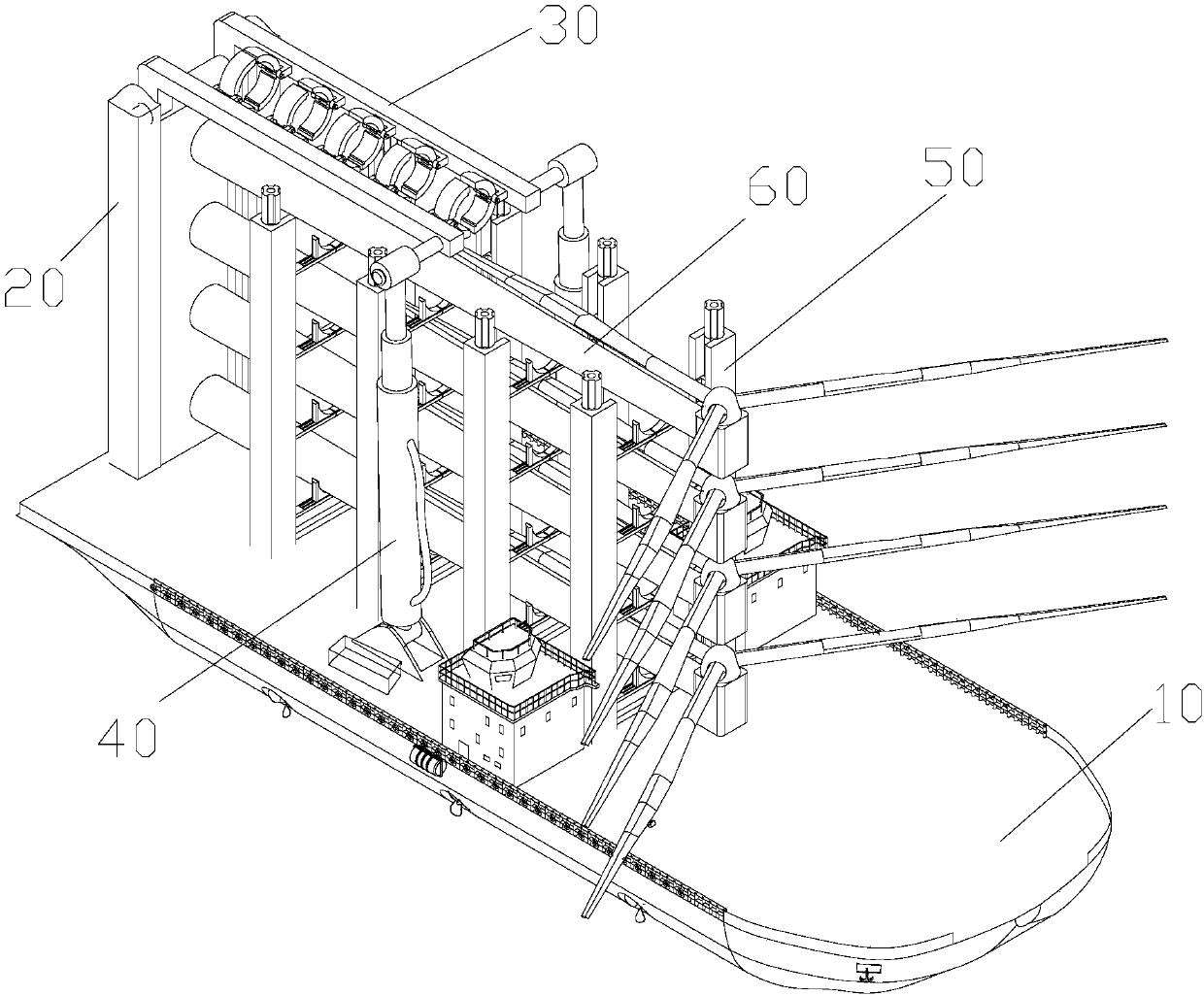

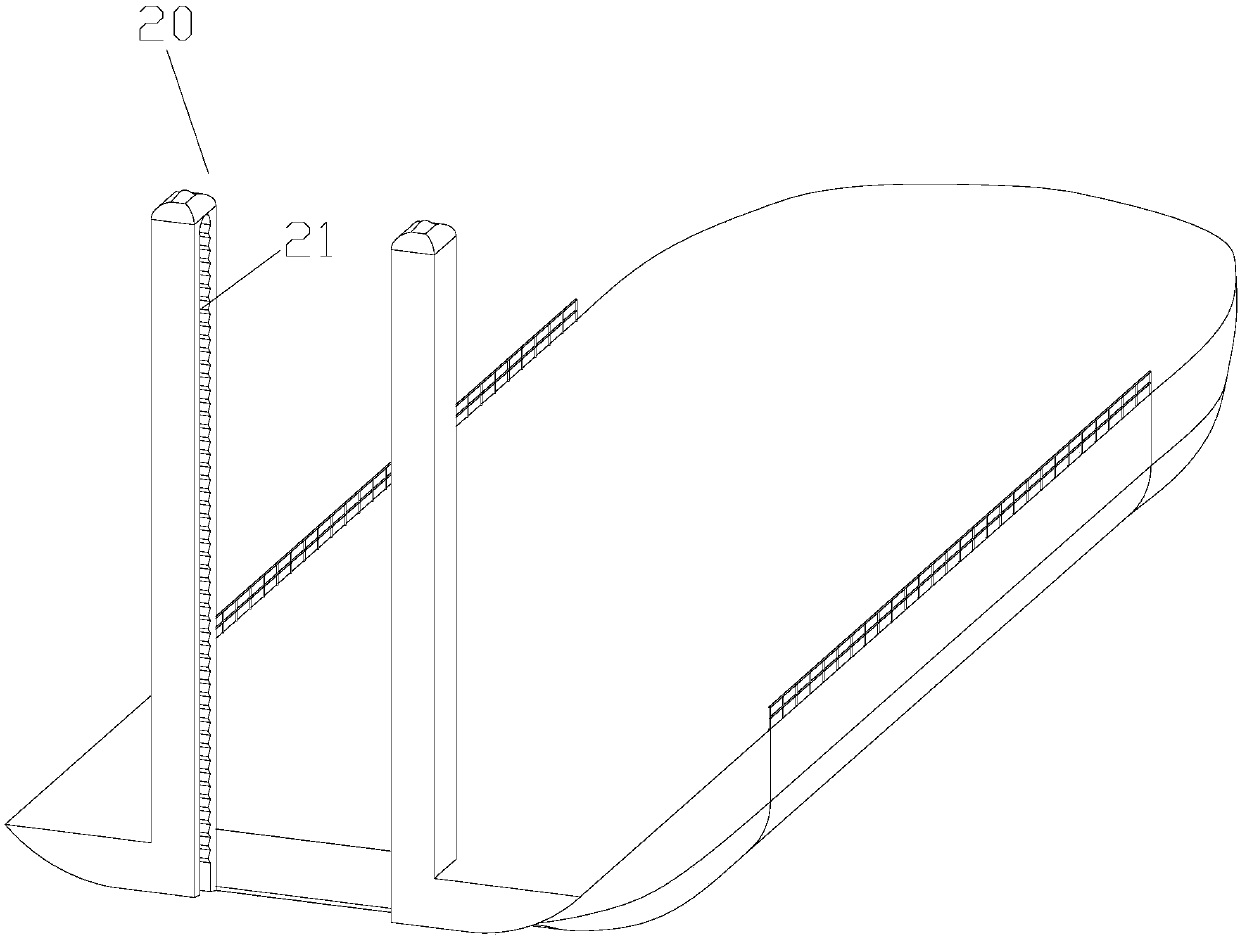

[0043] Such as figure 1As shown, it is a hydraulic inclined-push offshore wind turbine installation system in a preferred embodiment of the present invention, including: a wind turbine installation ship 10, a tail pillar 20 is vertically installed on the tail of the deck tail of the wind turbine installation boat 10, and the tail pillar 20 is arranged in the axial direction tail track 21;

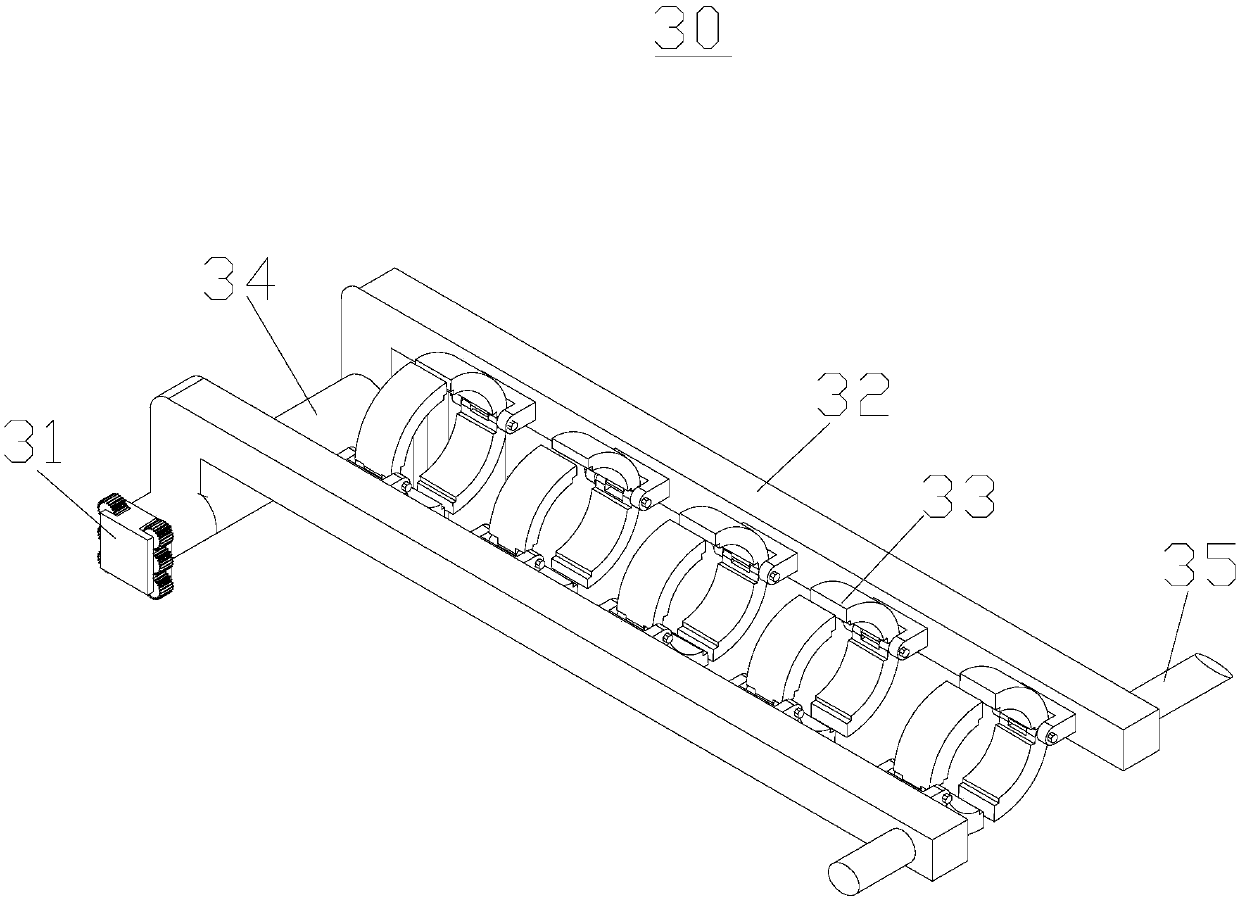

[0044] The rotating device 30 comprises a gear elevating device 31, a rotating arm 32 and a manipulator 33. The gear elevating device 31 can slide up and down along the tail track 21. One end of the rotating arm 32 is hinged with the gear elevating device 31. The manipulator 33 is installed on the rotating arm 32. The rotating arm 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com