Three-dimensional calibration sliding base

A sliding base, three-dimensional calibration technology, applied in the direction of mobile frame, engine frame, supporting machine, etc., can solve the problems of complex mechanical equipment, high production cost, difficult operation, etc., to achieve convenient later maintenance, low production cost, The effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

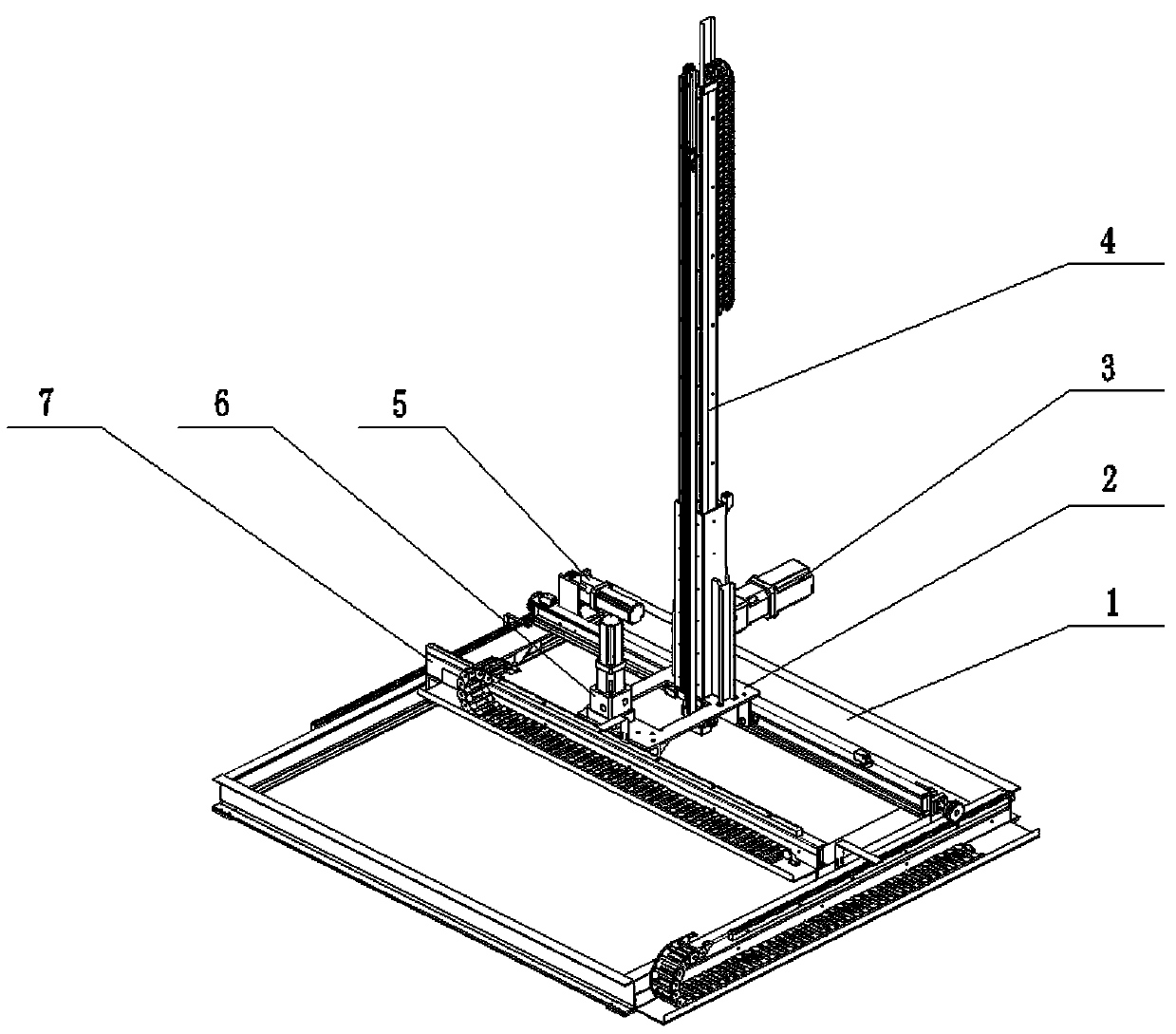

[0016] A three-dimensional calibration sliding base, including a base, a driving device, characterized in that: the base includes an X-axis base 1, a Y-axis base 7, and a Z-axis base 2; the X-axis base 1, Y-axis base 7, Z The axis bases 2 are all rectangular bases; the top surface of the X-axis base 1 is connected to the Y-axis base 7, and the top surface of the Y-axis base 7 is connected to the Z-axis base 2; the top surface of the X-axis base 1 is provided with a moving track, The top surface of the Y-axis is provided with a moving track; the bottom surface of the Y-axis base 7 is provided with a drive device corresponding to the moving track on the top surface of the X-axis base 1, and the bottom surface of the Z-axis base 2 is provided with a drive device corresponding to the Y-axis base 2. The drive device corresponding to the moving track on the top surface of the base 7; the Z-axis mechanical arm 4 is arranged on the top surface of the Z-axis base 2, and the Z-axis mecha...

Embodiment 2

[0020] The working principle of the present invention: the present invention can stably carry out three-axis coordinate positioning and movement, can be equipped with mechanical equipment such as mechanical arms or manipulators to work, and can well carry, pick up, and install parts of models such as ship models, and is easy to use and easy to operate. Simple; the invention controls the X-axis, Y-axis, and Z-axis through motors in different positions, which increases the flexibility of the equipment and facilitates the later maintenance of the equipment.

Embodiment 3

[0022] In the present invention, a mechanical device such as a mechanical arm can be installed on the Z axis, and a camera recognition device can also be installed for detailed observation. Through the observation and manipulation between two devices, it is convenient for the device to perform fine operations and increase the installation or disassembly of the device. the accuracy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com