Battery cell quality detection method

A quality inspection method and cell technology, applied in measuring devices, image data processing, instruments, etc., can solve problems such as the unrealistic distance between the tabs of the cell, and achieve the effects of ensuring process quality, reducing costs, and reducing detection deviations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0036] The invention proposes a battery quality detection method, adding a CCD detection system at the unloading place of the lithium battery winding machine to detect the distance between the tabs of the battery core and the distance between the tabs and the edge of the battery core; and analyze the results, the The judgment result is sent to the industrial computer of the lithium battery winding machine, and the industrial computer handles the cells with abnormal detection accordingly, so as to improve the process quality of the lithium battery.

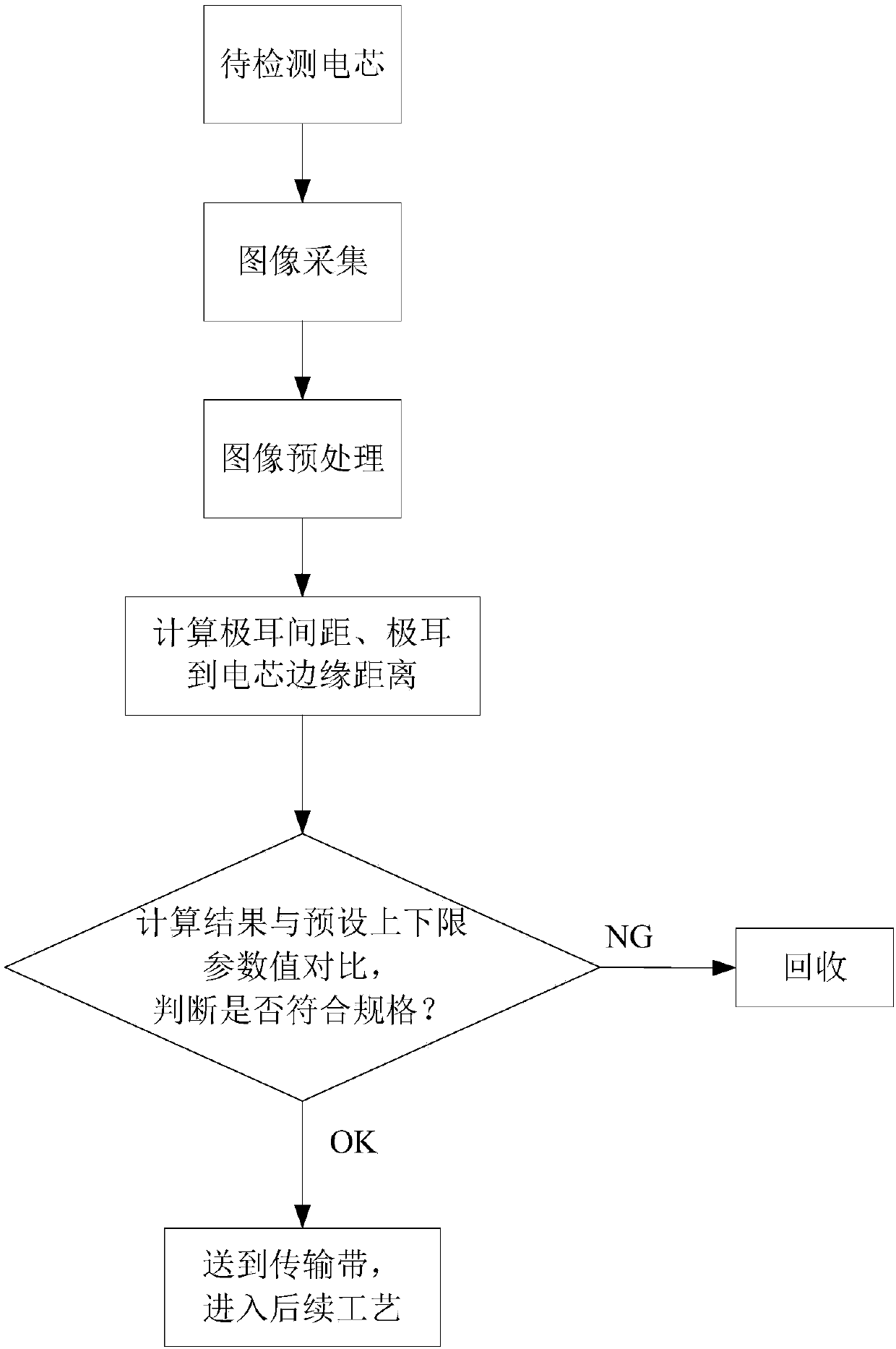

[0037] Such as figure 1 Shown, the present invention is realized through the following specific steps:

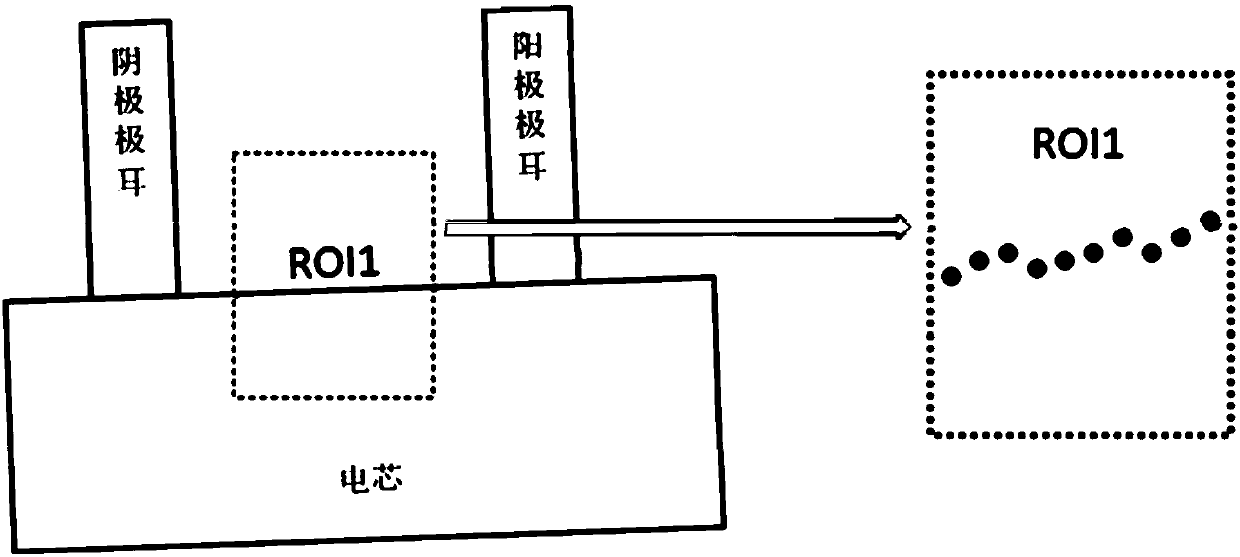

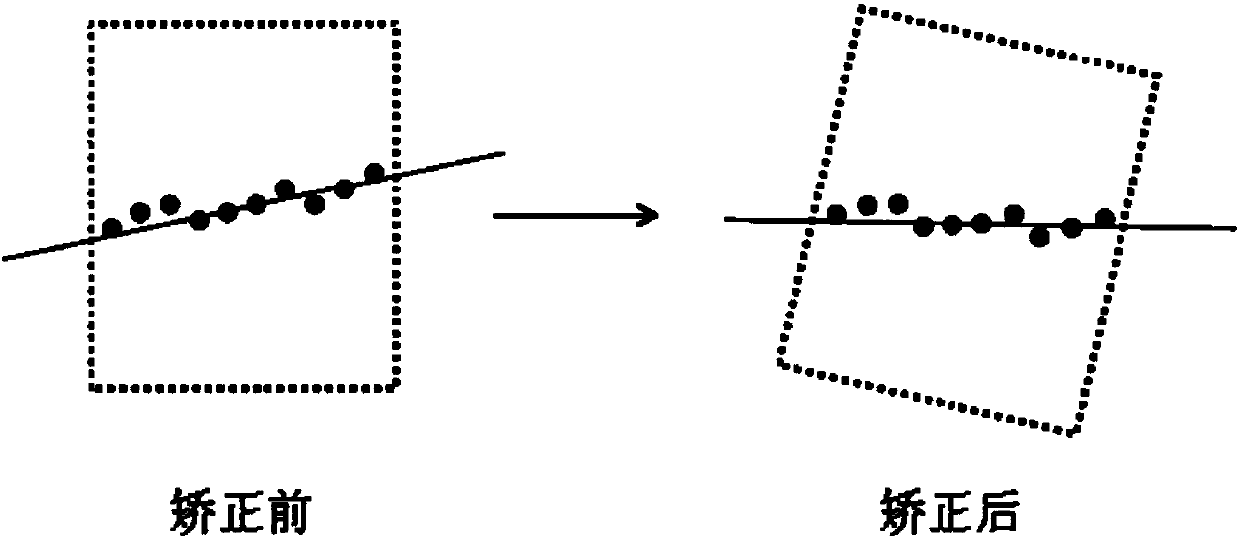

[0038] Step S1, through a set of mechanical operations, transfer the wound cell to the preset area of image acquisition; the cell is placed horizontally in the preset area; the image of the cell is collected b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com