Particle-swarm-genetic-algorithm-based selecting method of remanufacturing assembling process

A technology of genetic algorithm and assembly process, which is applied in the matching field of machine tool spindle box remanufacturing assembly process, can solve the problems of short precision life, poor machine tool precision, etc., achieve resource utilization rate improvement, significant technical and economic significance, and improve assembly The effect of accuracy and matching success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

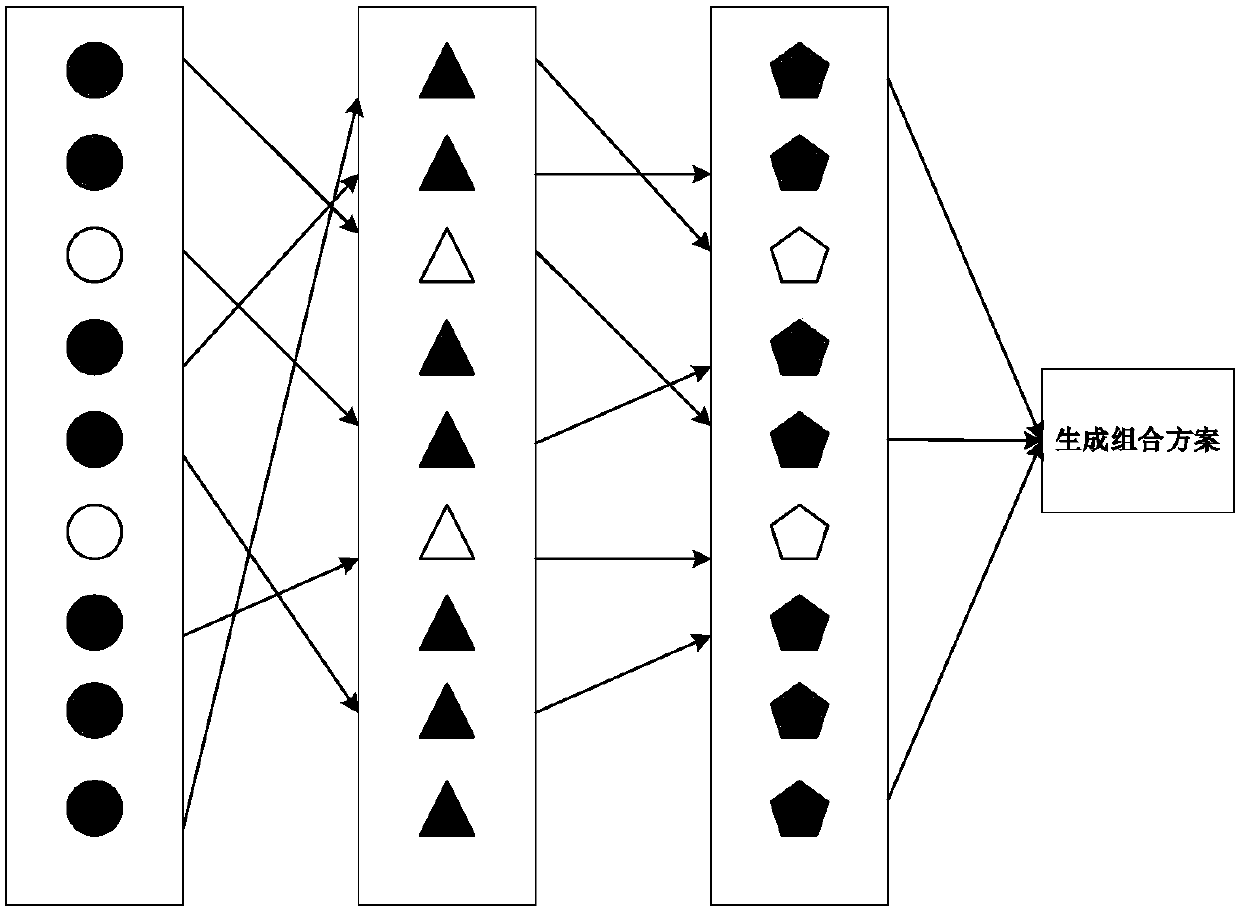

Method used

Image

Examples

Embodiment 1

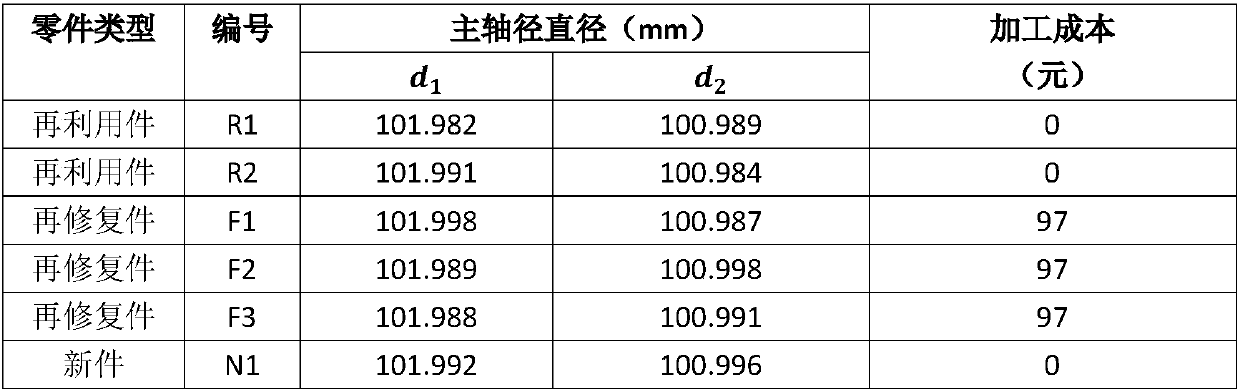

[0022] In order to ensure the assembly accuracy and performance of the remanufactured machine tool, the fit clearance of the main shaft assembly and the size of each component are controlled. The specific requirements for the fit clearance between the main shaft and the gear, and the design dimensions of the main shaft and gear parts are as follows:

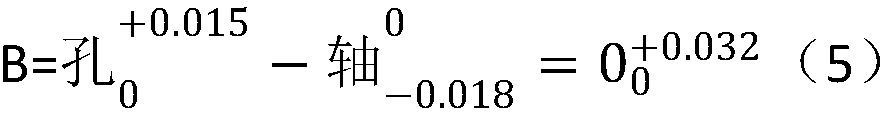

[0023] According to the requirements of remanufacturing assembly, the gap between the main shaft and the gear is required to be 0-0.020mm, and the diameter of the main shaft of the machine tool is D 1 The remanufactured processing size is Spindle diameter Gear 1 Inner Aperture Size Gear 2 Inner Aperture Size

[0024] The remanufacturing assembly of machine tools has higher requirements on the assembly accuracy of the spindle. Due to the limitation of existing technology and cost, the accuracy of the repaired parts is still low. Compared with the new machined parts, the degree of dispersion is slightly larger. If Using the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com