Motor leading cable

A motor lead and cable technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems of easy tearing of silicone rubber, no sheath protection of product structure, etc., to achieve good water and moisture resistance, chemical resistance. Good sex, low water absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

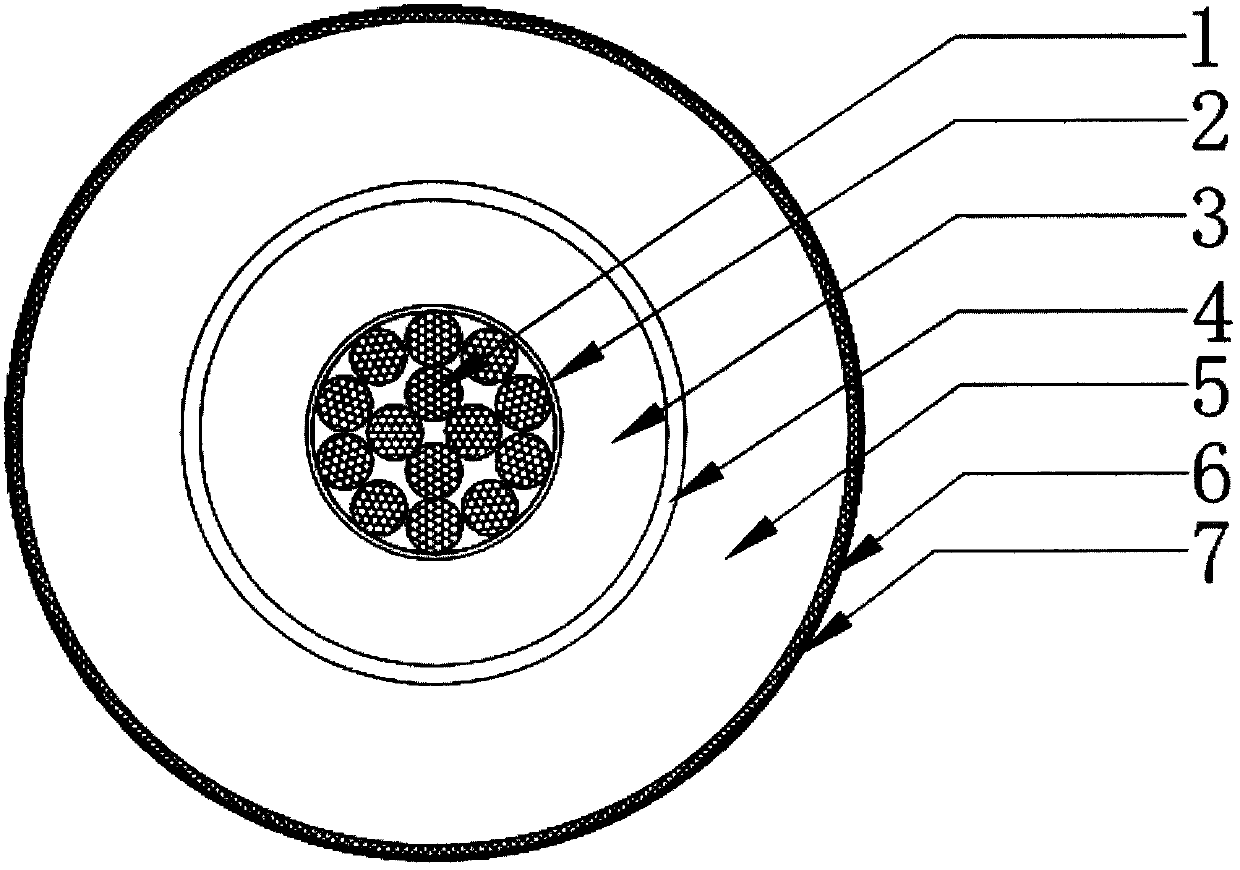

[0013] see figure 1 , a motor lead cable, a number of tinned annealed copper wires are twisted into strands at a certain pitch, several strands are re-twisted into a soft conductor 1 according to a certain pitch, and a number of soft conductors 1 are wrapped according to a certain overlapping rate One layer of ultra-thin isolation tape 2, ultra-thin isolation tape 2 outer extruded silicone rubber insulation 3, silicone rubber insulation 3 outer braided tinned annealed copper wire shielding layer 4, tinned annealed copper wire shielding layer 4 outer extruded wrapping 1 Flame retardant silicone rubber sheath protective layer 5, flame retardant silicone rubber sheath protective layer 5 braided outer high temperature resistant glass fiber reinforced layer 6, high temperature resistant glass fiber reinforced layer 6 coated with low smoke halogen free flame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com