Wiring sheet and coil framework provided with wiring sheet

A technology of coil bobbins and lugs, which is applied in the direction of coils, electrical components, circuits, etc., can solve the problems of suction noise movement stagnation, coil burnout, contact burnout, etc., to improve torque bearing capacity and lower bending process requirements , the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

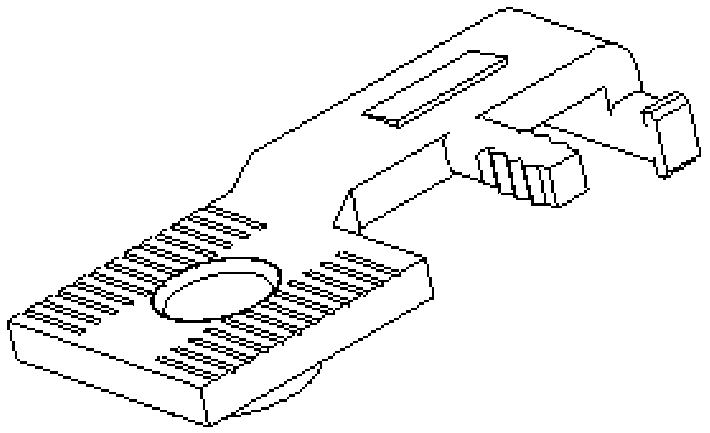

[0032] Such as Figure 4 As shown, a lug includes a positioning part 11 and a fastening part 12, the positioning part 11 is used to connect with the bobbin, the fastening part 12 is provided with a threaded through hole 121, and the threaded through hole 121 is used to connect the locking mechanism For example, screws, anti-slip lines 122 are provided on both sides of the threaded through hole 121; one side of the positioning part 11 has a bend 111, and the bend is used for sliding connection with the chute on the coil frame. Barbs 112 are provided on the contact surface between the bend 111 and the bobbin.

Embodiment 2

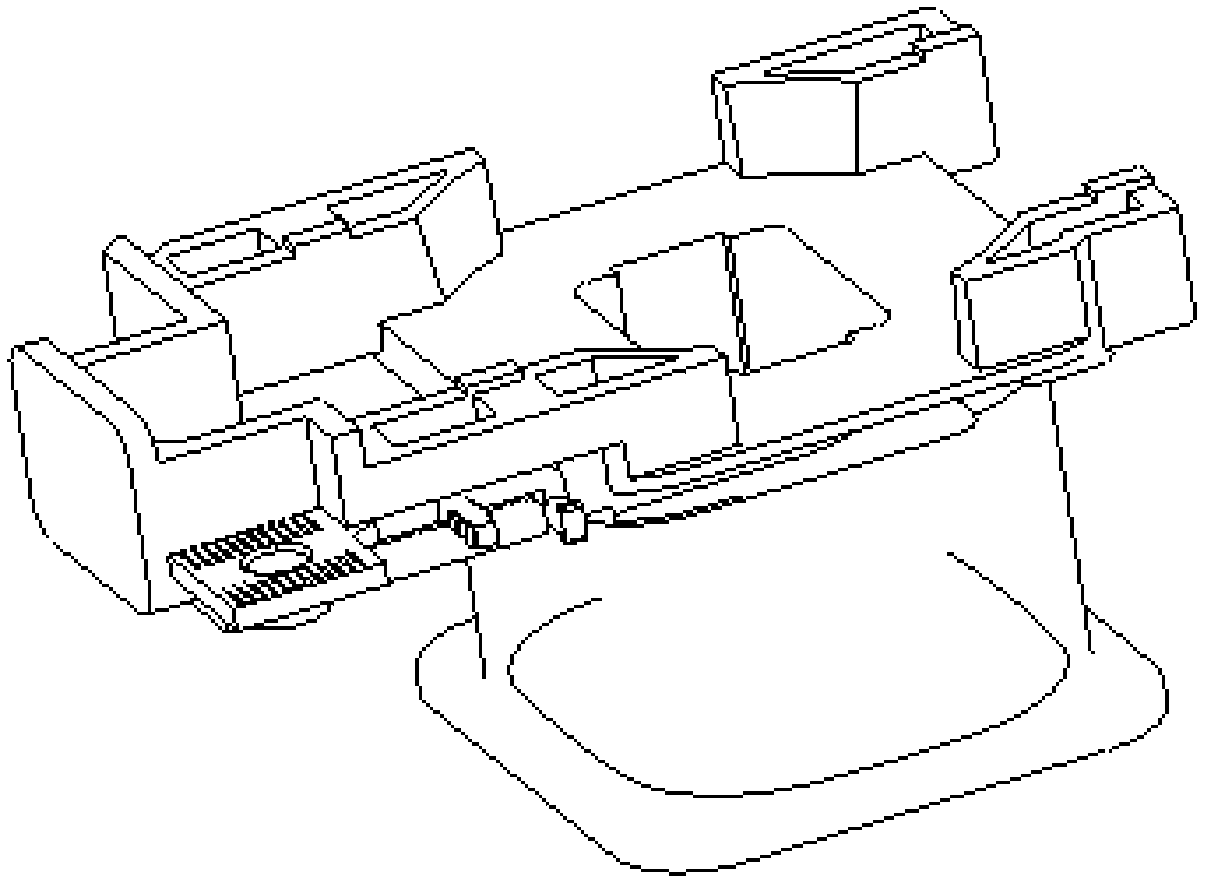

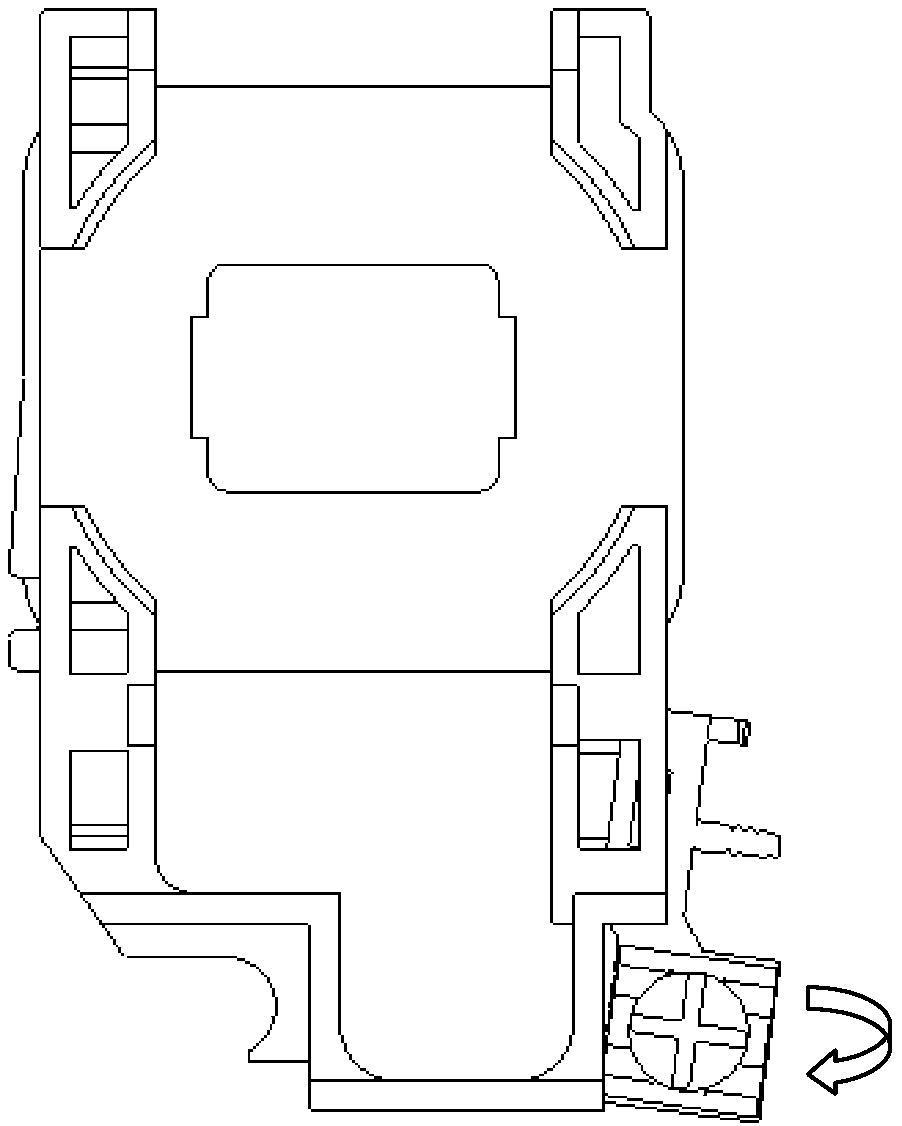

[0034] Such as Figure 5 As shown, a coil bobbin of a lug includes a support frame 21 and a winding reel 22, the support frame 21 has a square chute 211, and the contact surface between the bend 111 of the lug and the coil bobbin has a barb 112, The barb 112 is in interference fit with the chute 211 , and when the lug slides toward the support frame 21 , the interference value between the barb 112 and the chute 211 increases gradually, preventing the lug from loosening after assembly and the winding coming out.

[0035] In this embodiment, the lug and the coil frame do not need to be limited by bosses. A bending surface is added to the side of the lug, and a deep groove is added in the coil bobbin. Through the large-area limit, the screwdriver can withstand the force of the lug in the direction of tightening the screw. Torque, the plastic block does not fall off during the assembly process, thus avoiding the noise of the iron core caused by the plastic block falling to the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com