Silicon chip underwater automatic taking and inserting machine

A chip insertion machine and silicon chip technology, which is applied in the manufacture of conveyor objects, electrical components, semiconductor/solid-state devices, etc., can solve problems such as unfavorable installation, high manufacturing cost, and complicated device structure, so as to improve work efficiency and reduce manufacturing costs. Low, to avoid the effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

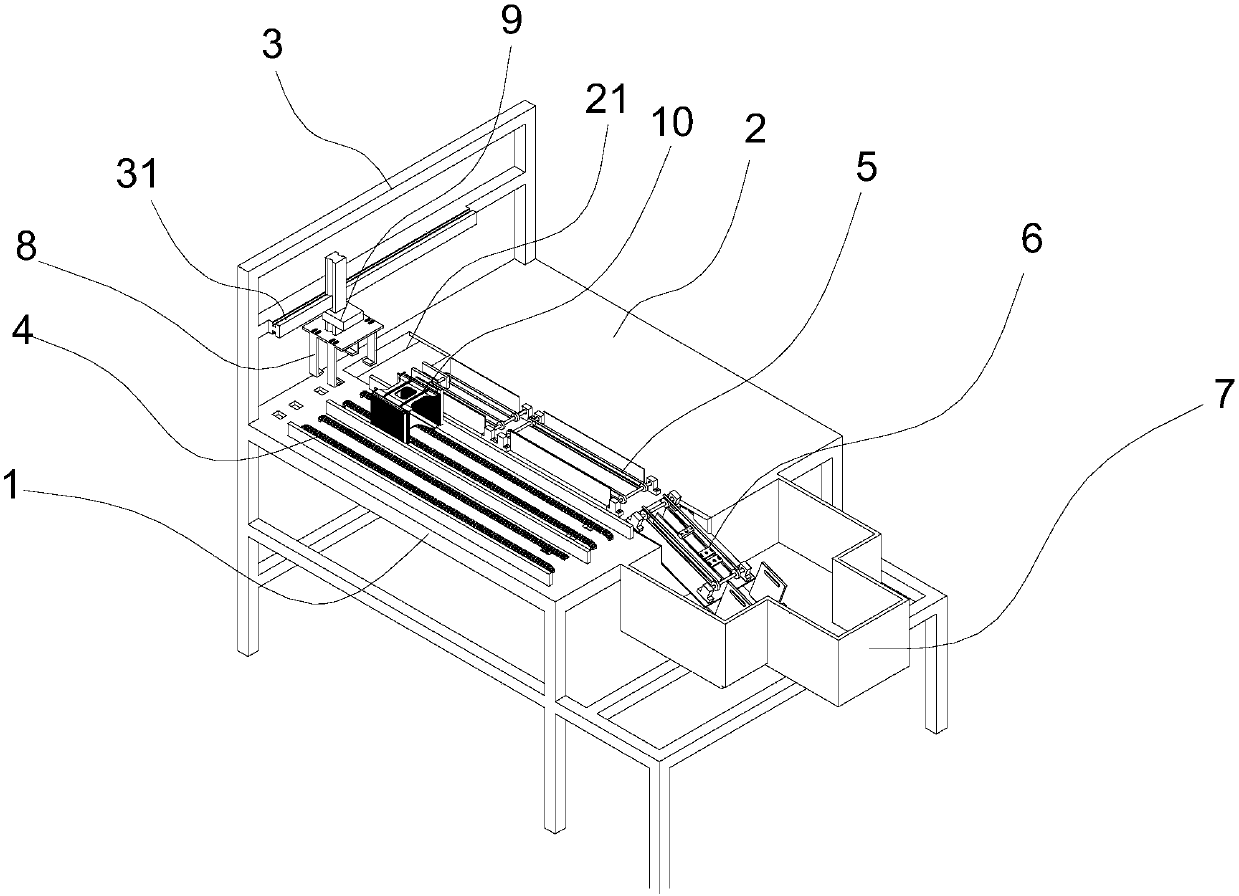

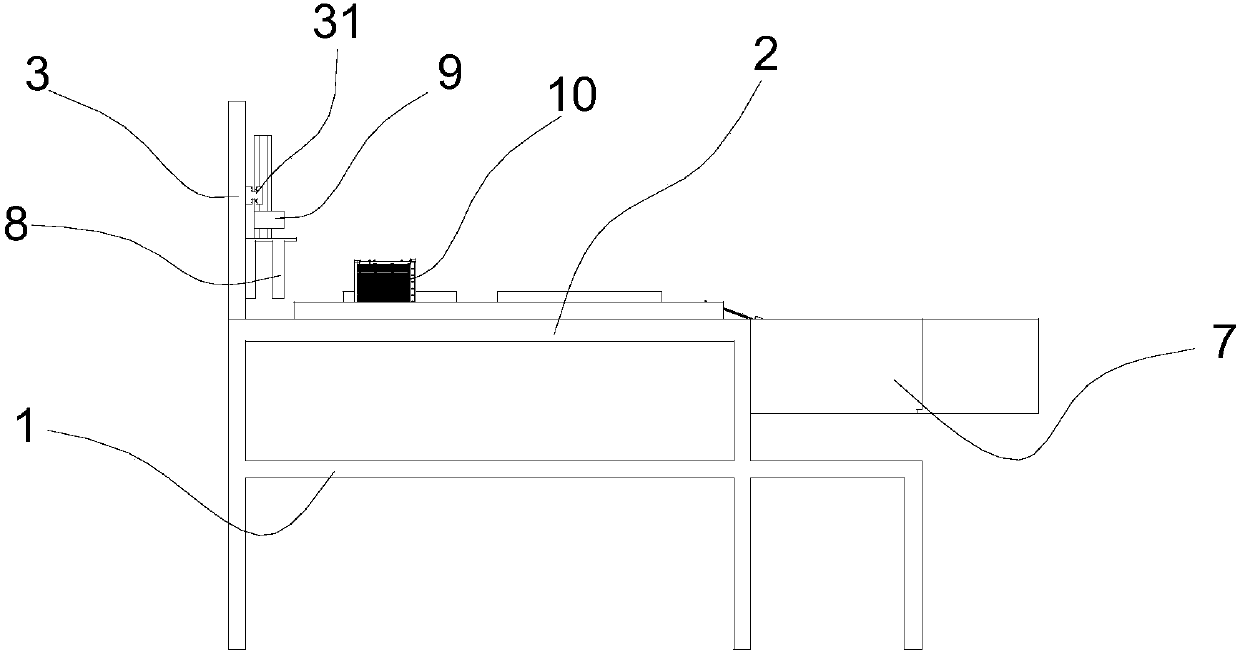

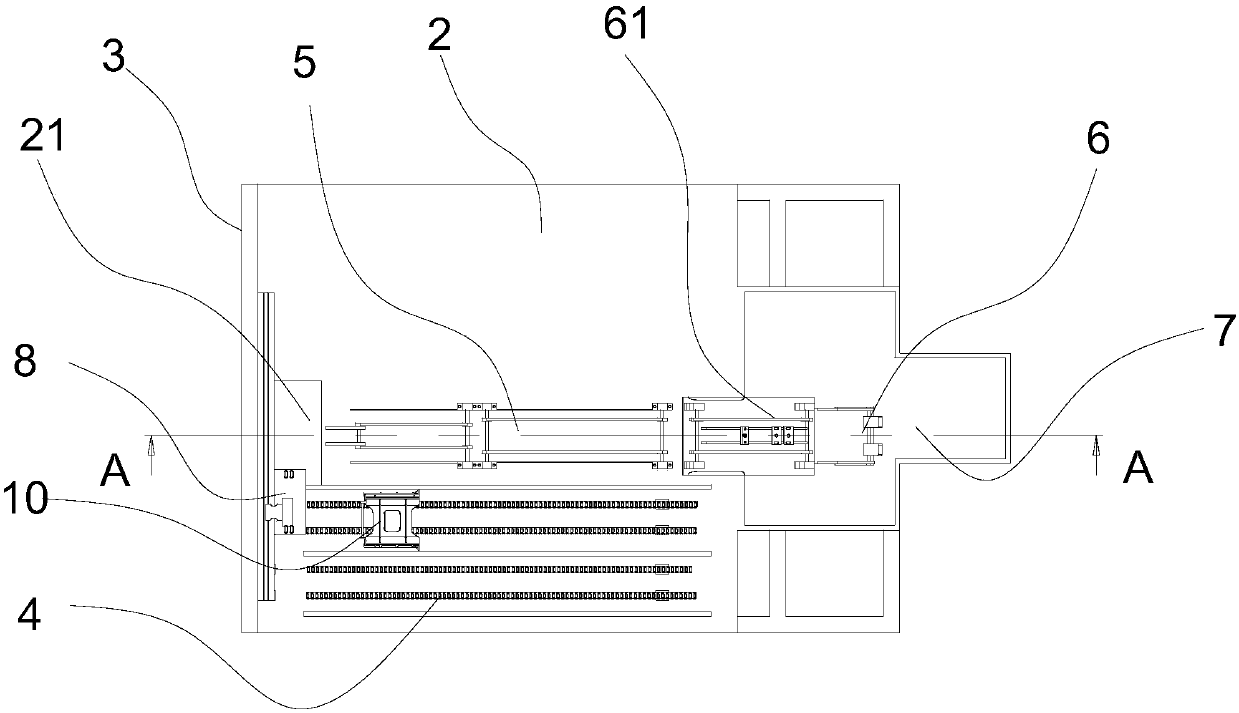

[0029] Such as Figure 1 to Figure 7 As shown, the silicon wafer underwater automatic chip taking and inserting machine according to the present invention includes a frame 1, and the frame 1 is provided with an installation platform 2, and the installation platform 2 is provided with flower basket conveyor belts 4 parallel to each other. and a silicon wafer conveyor belt 5; one end of the frame 1 is provided with a cleaning box 7, and the other end is provided with a vertical mounting bracket 3; Material device 6;

[0030] The vertical mounting bracket 3 is provided with a horizontal sliding device 31, and the horizontal sliding device 31 is connected with a vertical flower basket jaw 8, and the flower basket jaw 8 is connected with the horizontal sliding device 31 through a lifting device 9;

[0031] The installation platform 2 is located at one end ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap