Method for controlling cascaded multi-cell high-power high-frequency ice melting power supply

A technology of power control and high power, which is applied to the installation of output power conversion devices, electrical components, and cables, etc. It can solve the problem of large harmonics in the input power supply for ice-melting excitation, reduced safety of ice-melting power supply, and low quality of input current, etc. problem, to achieve the effect of improving safety, solving large harmonics, and suppressing input side harmonics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The invention provides a control method to realize parallel connection of power units to output high-frequency and large current, and provides a new ice-melting method for ice-covered lines of power grids in winter.

[0032] The rectification and inversion of the high-frequency ice-melting power supply of the present invention adopt full-control devices, and the control of the power unit includes two parts: the rectification bridge and the inverter H-bridge control.

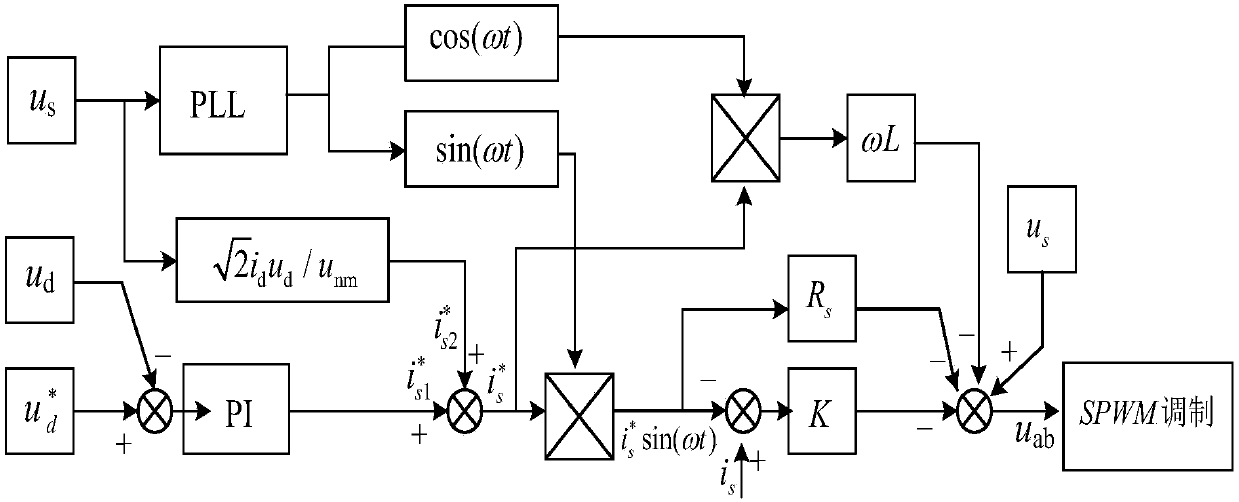

[0033] (1) Instantaneous direct current control is used on the input side to realize unit power factor rectification on the input side. The direct current control is composed of a double closed-loop control of the current inner loop and the voltage outer loop, which can effectively suppress the input side harmonics and improve the ice-melting excitation. The quality of the source input current;

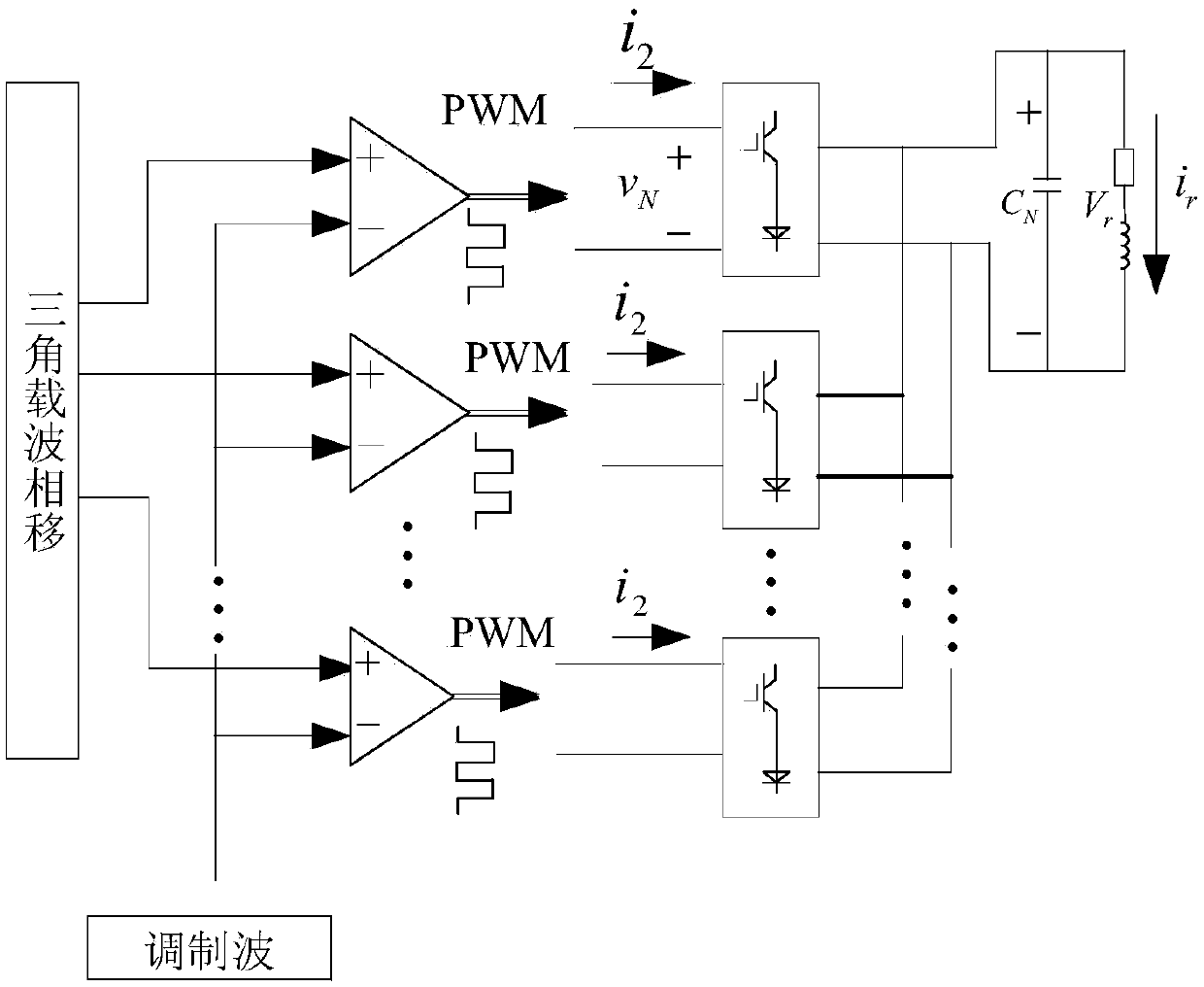

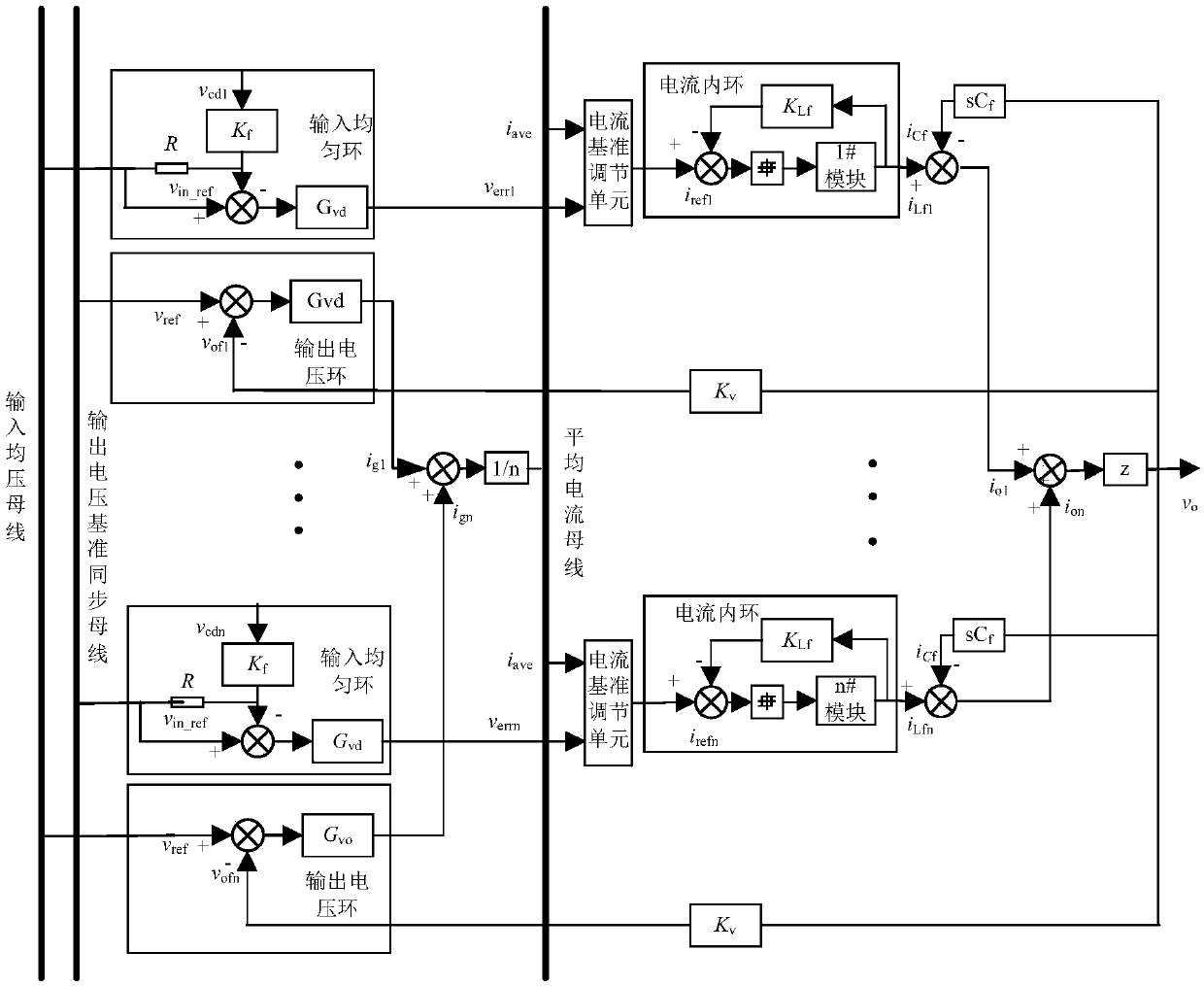

[0034] (2) The inverter unit adopts SPWM multiplexing, input voltage equalization, and output current equalizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com