Uniform heating plate cooling device with support post structure and fabrication method of cooling device

A technology of heat dissipation device and vapor chamber, which is applied to structural parts of electrical equipment, modification by conduction heat transfer, cooling/ventilation/heating transformation, etc. Increase in size, capillary limit, low condensation limit, etc., to achieve the effect of improving capillary limit and thermal conductivity, improving heat dissipation performance, and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

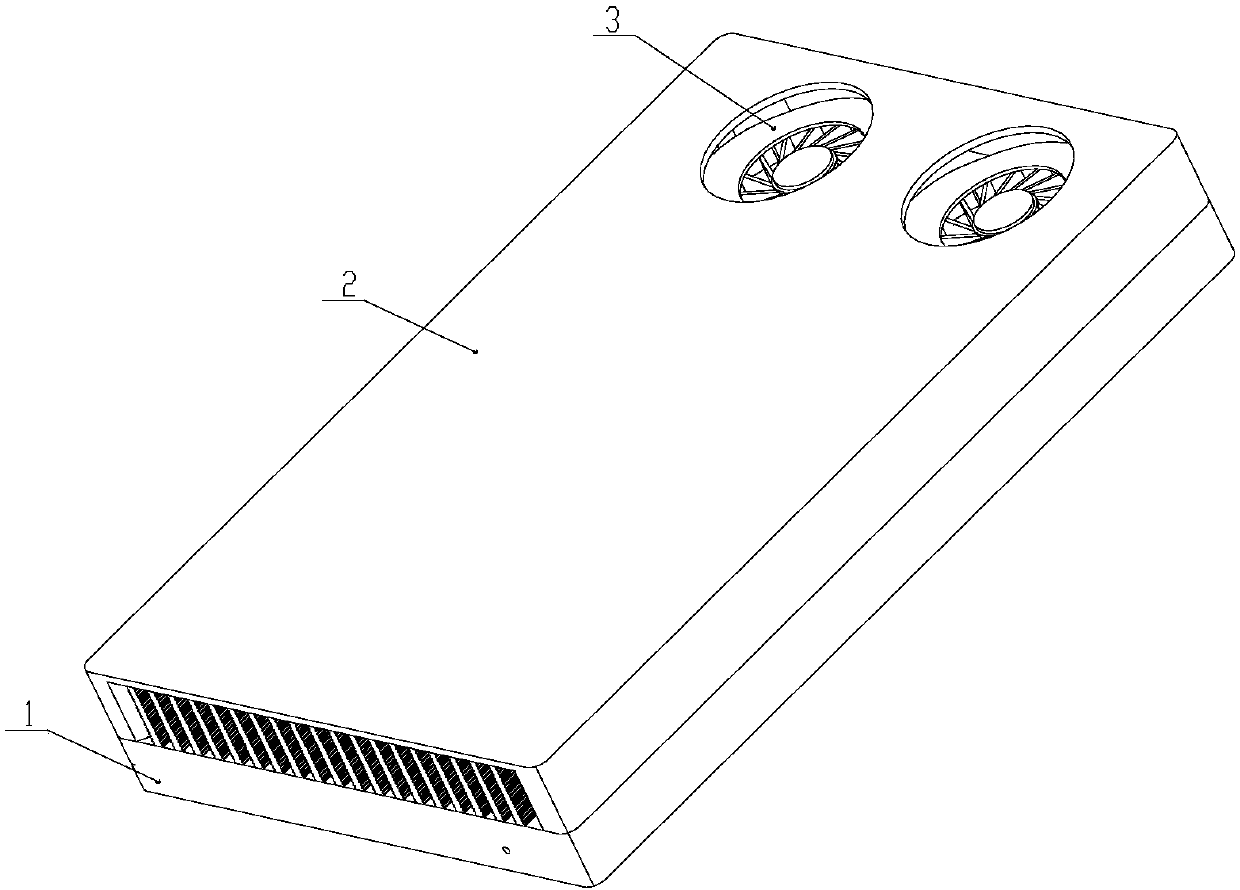

[0065] A vapor chamber cooling device with a support column structure, comprising a vapor chamber radiator 1 with a support column structure, a windshield 2 and a vortex fan 3, such as figure 1 shown;

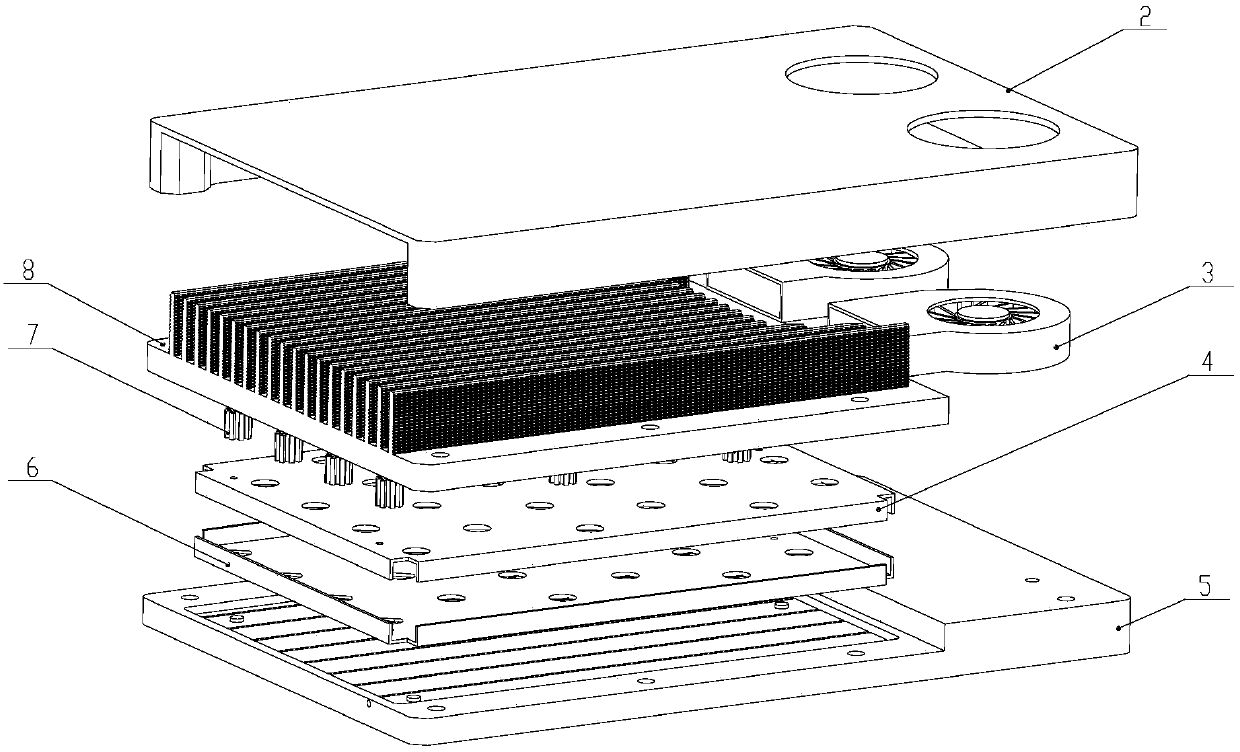

[0066] Such as figure 2 As shown, the vapor chamber radiator 1 is composed of an upper cover plate 8, a lower cover plate 5, a composite reflow structure, a support column 7 and a nano-liquid working medium, and the upper cover plate 8 and the lower cover plate 5 are welded to form a vapor chamber working chamber , the support column 7 is welded to the inner surface of the chamber of the vapor chamber to enhance the strength of the vapor chamber shell and eliminate the influence of the steam pressure of the internal working medium on the shell; the composite reflow structure consists of the upper cover groove 9, the second The wire mesh capillary liquid-absorbing core 4, the lower cover plate groove 12, the second wire mesh capillary liquid-absorbing core 6 and the support co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com