Gear shaping clamp for flange of transmission

A transmission and fixture technology, applied in the field of clamping devices for workpieces, can solve problems such as poor clamping effect, inconvenient installation and disassembly, and difficulty in providing clamping force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

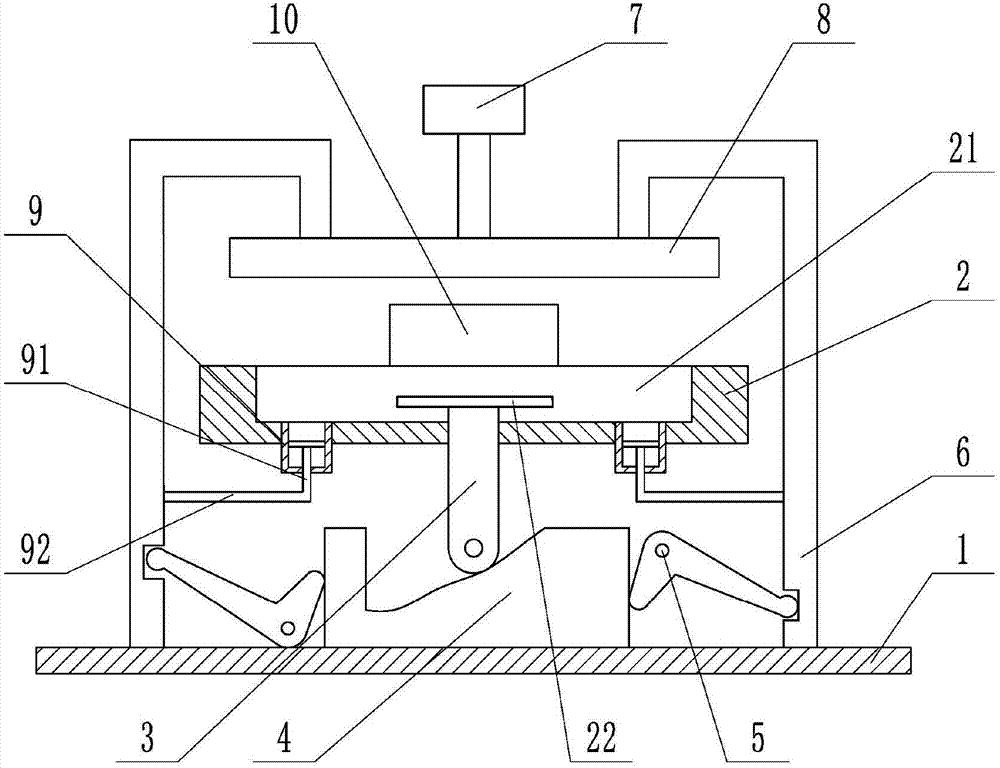

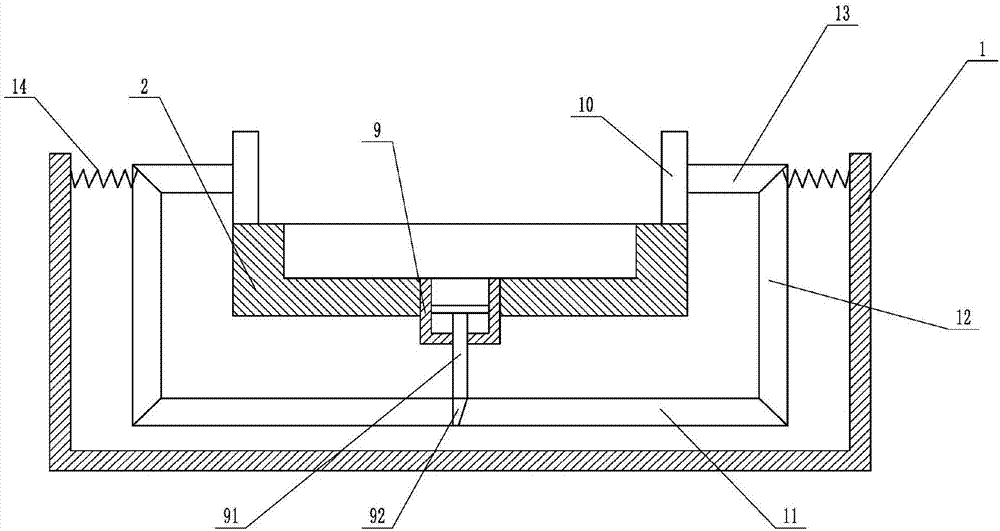

[0021] The reference signs in the drawings of the description include: frame 1, positioning plate 2, positioning notch 21, circular bottom plate 22, support rod 3, cross bar 4, "V"-shaped driving rod 5, push rod 6, cylinder 7 , Annular platen 8, piston cylinder 9, piston rod 91, horizontal rod 92, clamping block 10, first wedge bar 11, second wedge bar 12, third wedge bar 13, spring 14.

[0022] Such as figure 1 As shown, the gear shaper fixture for the transmission flange includes a frame 1, a linkage device and two clamping devices. A positioning disc 2 is welded on the frame 1, and a positioning notch 21 for placing the flange is opened on the positioning disc 2. , the positioning notch 21 is also slidingly connected with a circular bottom plate 22, the center of the circular bottom plate 22 coincides with the center of the positioning notch 21, and the diameter of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com