Novel spray nozzle of 3D printer

A 3D printer, a new type of technology, used in 3D object support structures, additive manufacturing, coating devices, etc., can solve the problems of rough surface of the workpiece, uneven wire output, poor quality, etc., to achieve fine and comfortable surface of the workpiece, good heat dissipation , to ensure the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

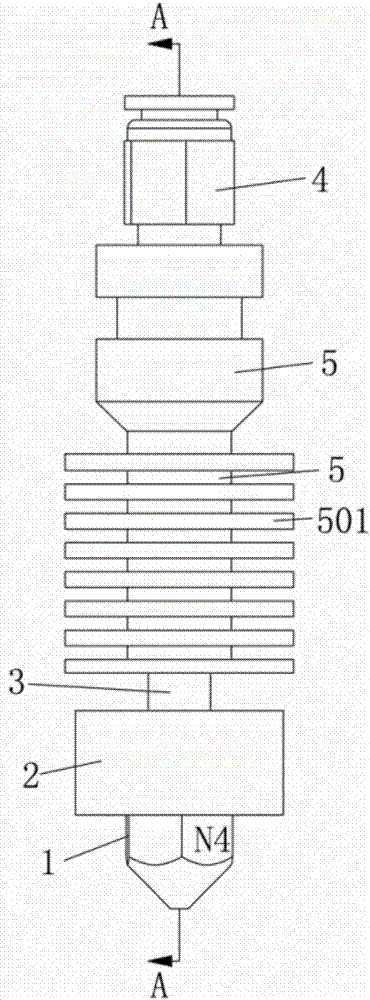

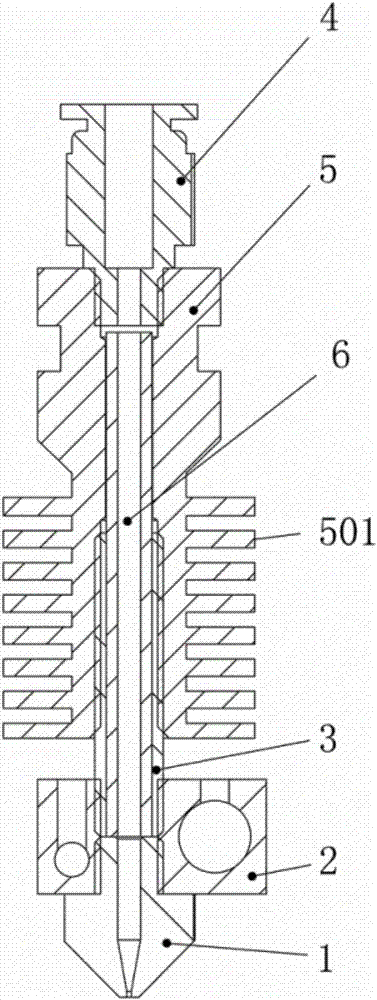

[0009] like figure 1 and figure 2 As shown, the present invention includes a nozzle 1 and a heating device 2 set on the nozzle 1. The upper end of the nozzle 1 is fixed with a stainless steel tube 3 communicating with the spray chamber in the nozzle 1. The upper end of the stainless steel tube 3 is connected with a raw material guide pipe 4. The stainless steel tube 3 is covered with an aluminum alloy cooling head 5, which is characterized in that the outer circumference of the aluminum alloy cooling head 5 is provided with cooling fins 501, the stainless steel tube 3 is penetrated with a polytetrafluoroethylene tube 6, and the upper end of the polytetrafluoroethylene tube 6 is The raw material guide pipe 4 is connected, and the lower end of the polytetrafluoroethylene pipe 6 is placed on the upper end of the spray cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com