Buffer layer of functional shoe sole

A buffer layer and functional technology, applied in the field of shoe parts, can solve the problems of poor anti-skid shock absorption effect and large weight, and achieve the effect of simple overall shape, improved shock absorption, and satisfaction of public needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

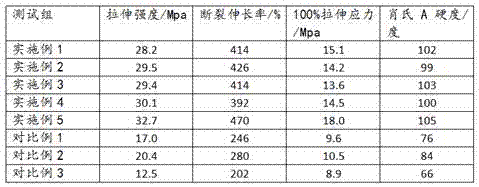

Examples

Embodiment 1

[0016] A buffer layer for functional shoe soles, characterized in that it comprises the following components in parts by weight: polyisoprene 85, cyclohexylthiomaleimide 9, tetraalkylthiuram disulfide 6, 1,4-diaminobutane 8, polyacrylamide 16, polystyrene nanospheres 23, polylactic acid fiber 31, ethyl silicate 8, kaolin 11.

Embodiment 2

[0018] A buffer layer for functional shoe soles, characterized in that it comprises the following components in parts by weight: polyisoprene 105, cyclohexylthiomaleimide 15, tetraalkylthiuram disulfide 11, 1,4-diaminobutane 17, polyacrylamide 25, polystyrene nanospheres 29, polylactic acid fiber 45, ethyl silicate 15, kaolin 23.

Embodiment 3

[0020] A buffer layer for functional shoe soles, comprising the following components in parts by weight: polyisoprene 100, cyclohexylthiomaleimide 14, tetraalkylthiuram disulfide 10, 1,4- Diaminobutane 15, polyacrylamide 22, polystyrene nanospheres 28, polylactic acid fiber 43, ethyl silicate 13, kaolin 20.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile stress | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com