Diversion structure, mixed flow fan and range hood

A mixed-flow fan and range hood technology, which is applied in the direction of removing oil fume, machines/engines, and mechanical equipment, etc., can solve the problems of reducing the exhaust air volume of the range hood, high power consumption of the centrifugal fan, and low air pressure, and achieve the effect of exhausting oil fume. The effect of a good, good cooking environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

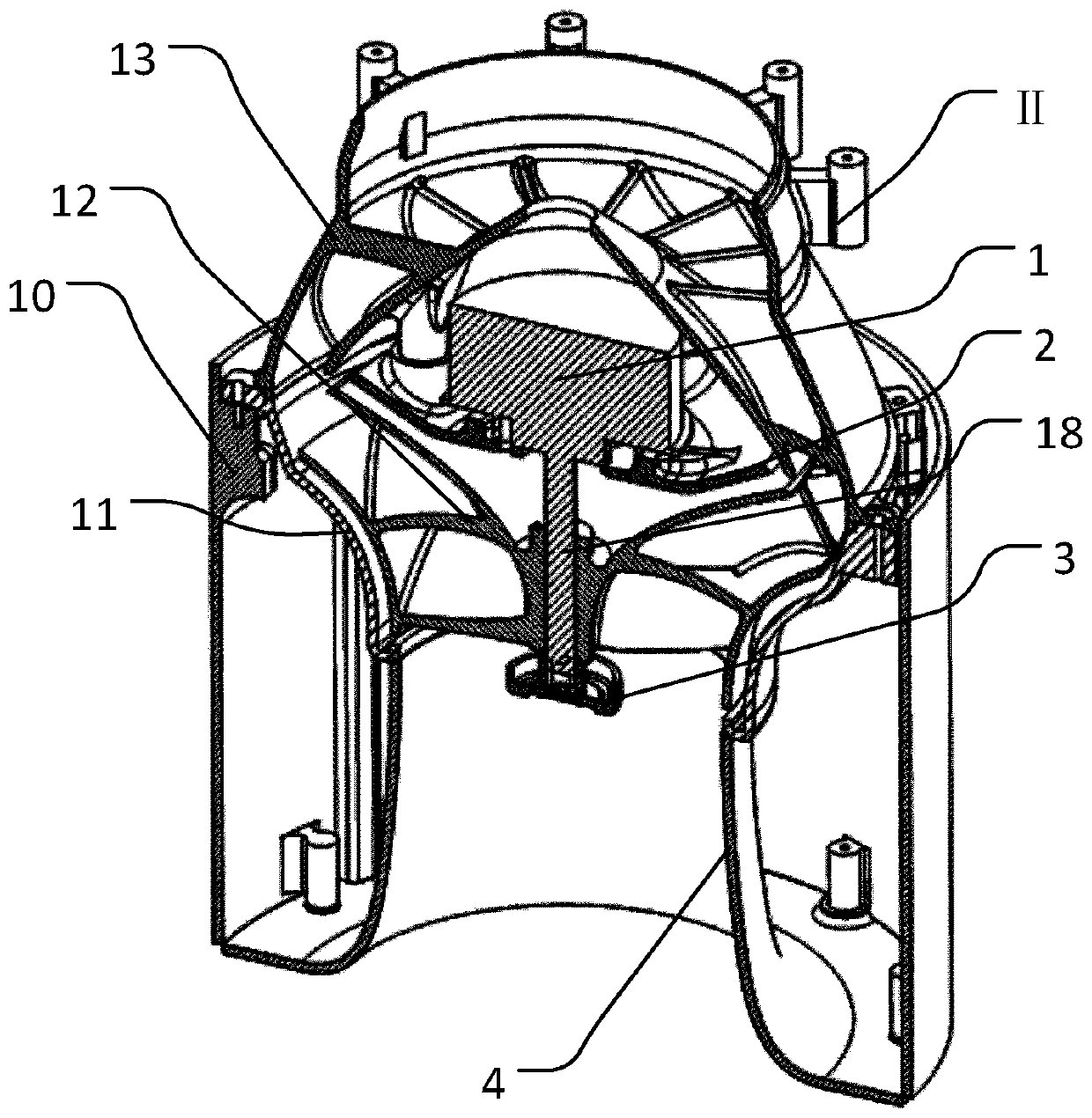

[0028] The present invention is described below based on the embodiments, and those skilled in the art should understand that the drawings provided here are for the purpose of illustration, and the drawings are not necessarily drawn to scale.

[0029] Unless the context clearly requires, throughout the specification and claims, "comprises", "comprises" and similar words should be interpreted in an inclusive sense rather than an exclusive or exhaustive meaning; that is, "including but not limited to" meaning.

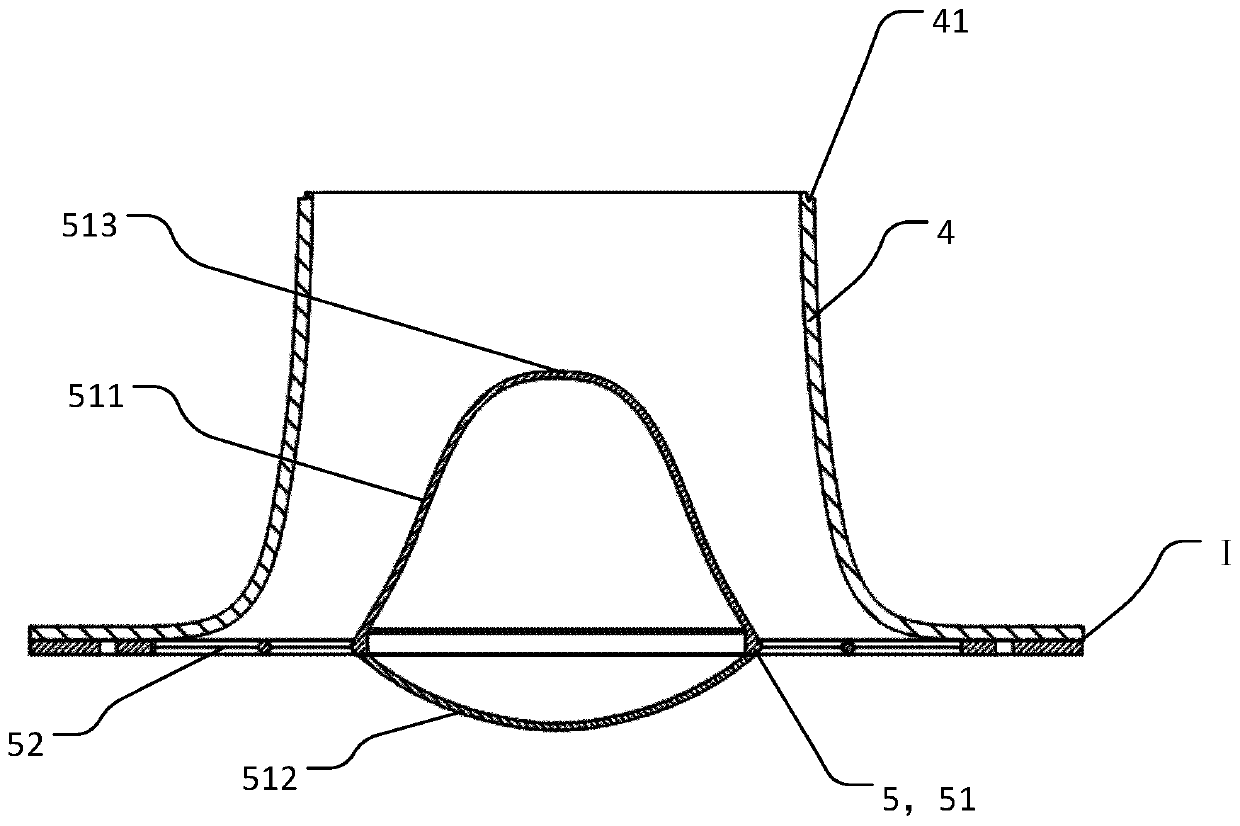

[0030] The above and below described in this application specification Figure 5 The orientation shown in the Figure 5 The up and down directions shown in are respectively the up and down directions in this application, and the cross section in this application refers to the Figure 5 The vertical section in the vertical direction.

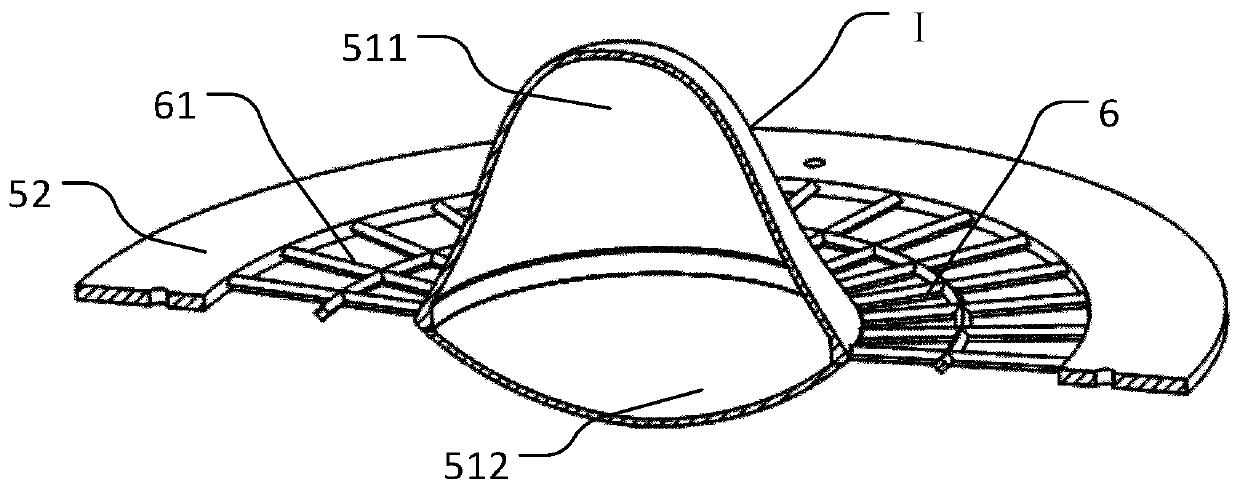

[0031] Such as figure 1 , figure 2 , Figure 5 As shown, the flow guide structure I provided by the present application includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com