Skin rolling-up and sticking method for fireworks

A firecracker and shroud technology, which can be used in fireworks, offensive equipment, weapon types, etc., can solve problems such as low work efficiency, poor product consistency, and unguaranteed yield rates, and achieve high production efficiency, compact structure, and improved efficiency. and safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

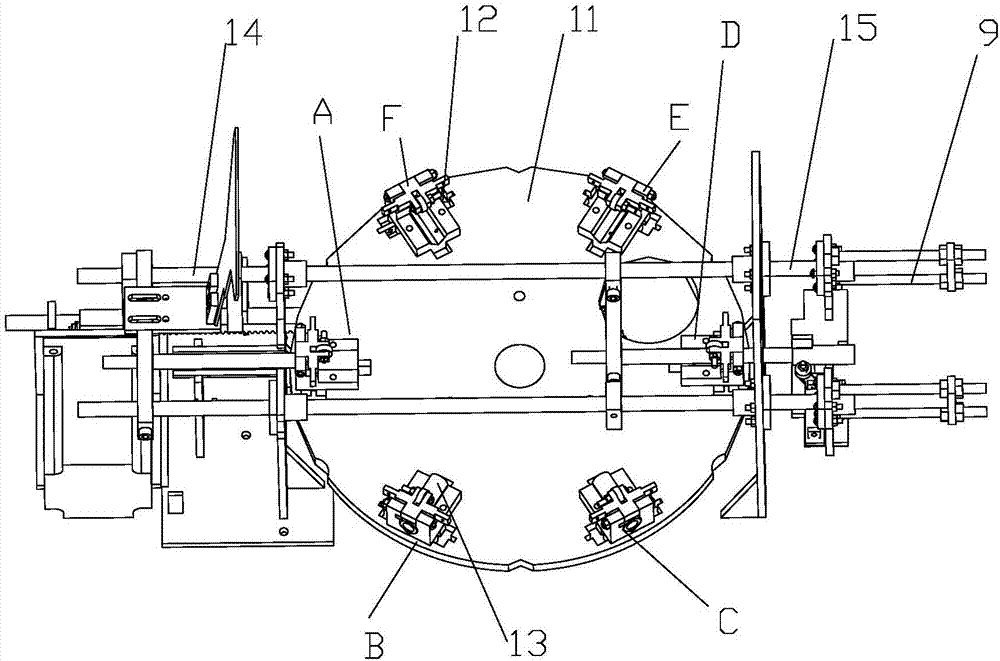

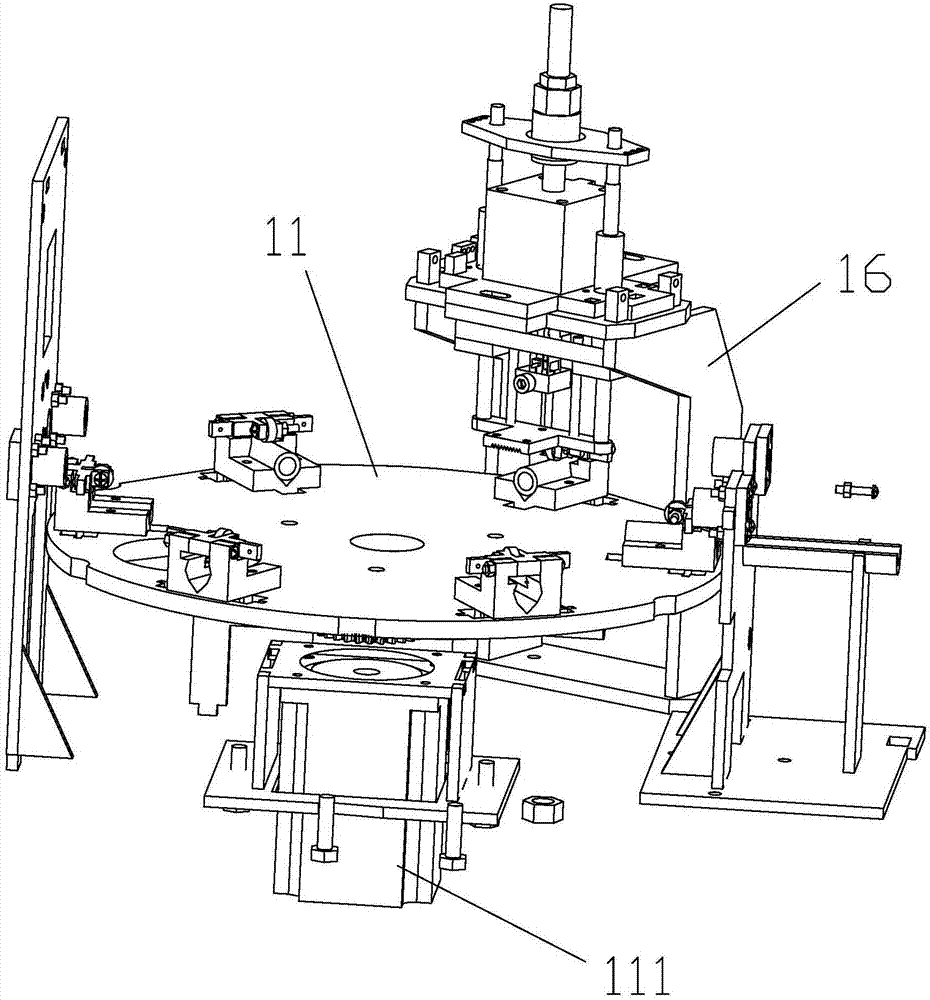

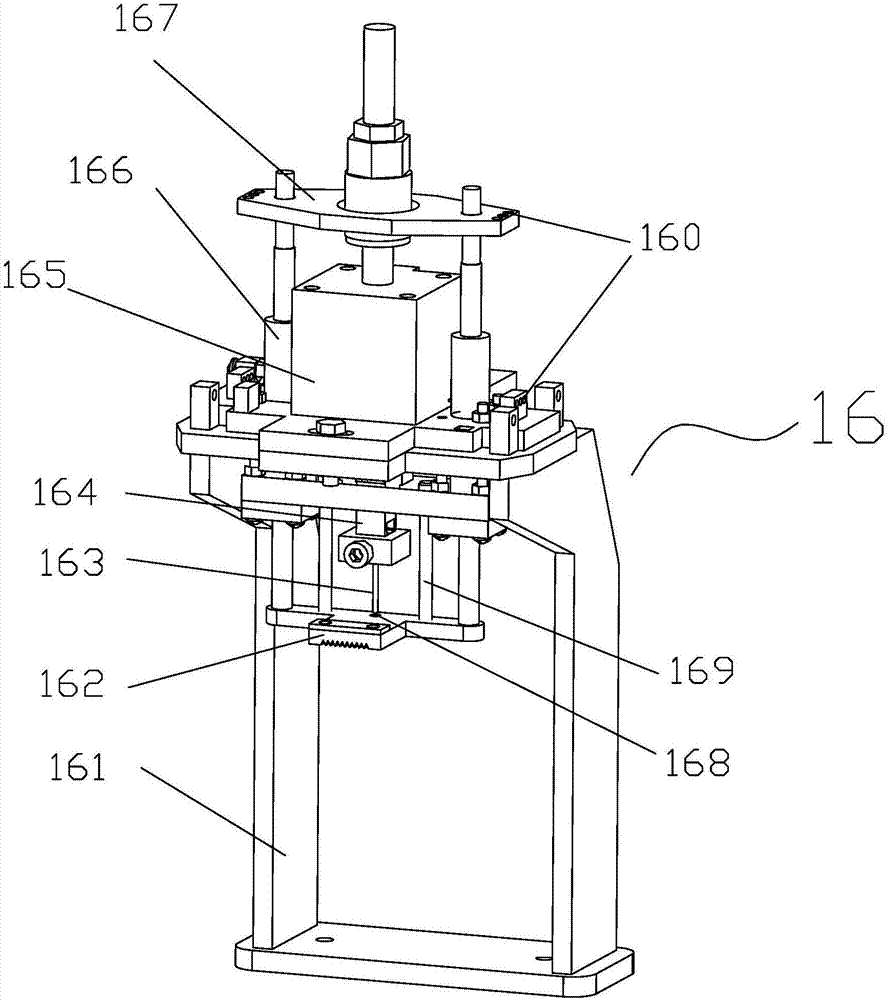

[0064] A firecracker manufacturing system, including a feeding device, a planting device and a peeling device;

[0065] The feeding device is used to send fireworks into the planting device;

[0066] The planting device is used to drill a hole in the shell of the firecracker, and insert a lead wire in the hole; the planting device is the planting device described in claim 4;

[0067] The peeling device is used to roll the skin on the firecracker after the lead wire has been planted.

[0068] Such as Figure 15 , the blanking mechanism includes a hopper 81, a blanking bracket 84, a blanking roller 82, an arc-shaped blanking auxiliary part 85 and a blanking channel 83;

[0069] The hopper is fixed above the feeding bracket; the width of the upper end of the hopper is greater than the width of the lower end;

[0070] The blanking roller, the arc-shaped blanking auxiliary part and the blanking channel are all installed on the blanking bracket; the blanking roller and the arc-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com