Horizontal plugboard type aerospace integrated electronic single machine structure

A comprehensive electronic and plug-in technology, applied in the direction of component plug-in combination, circuit layout on support structure, etc., can solve the problem of reducing the reliability of system electromagnetic compatibility system signal transmission, failing to meet system development requirements, reducing system environmental adaptability, etc. problems, to achieve the effect of improving environmental adaptability, reasonable center of gravity, and reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings, so as to help understand the content of the present invention.

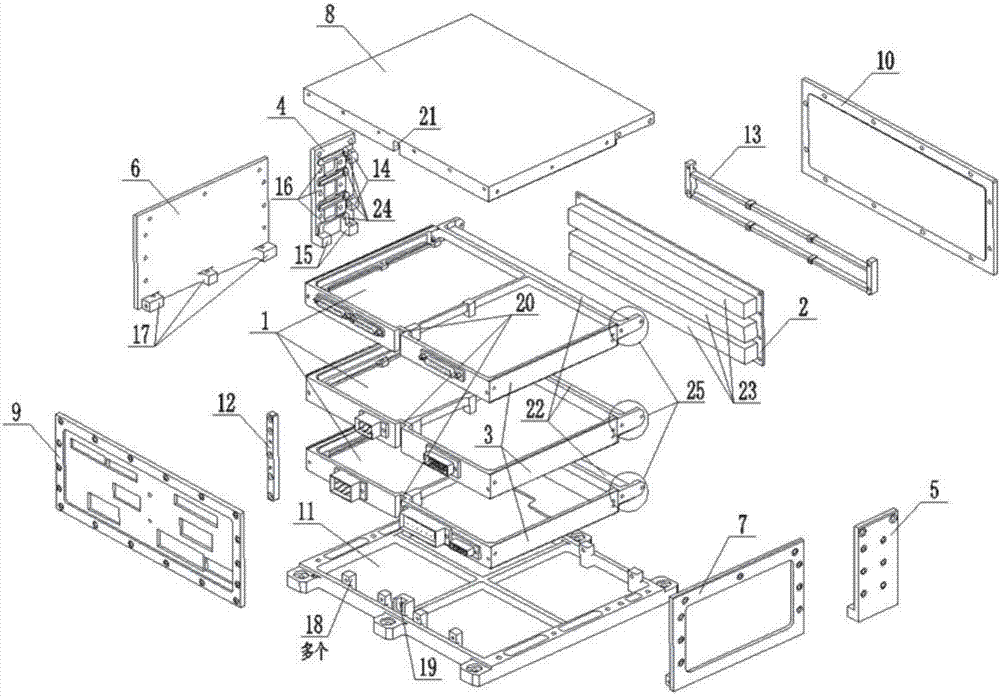

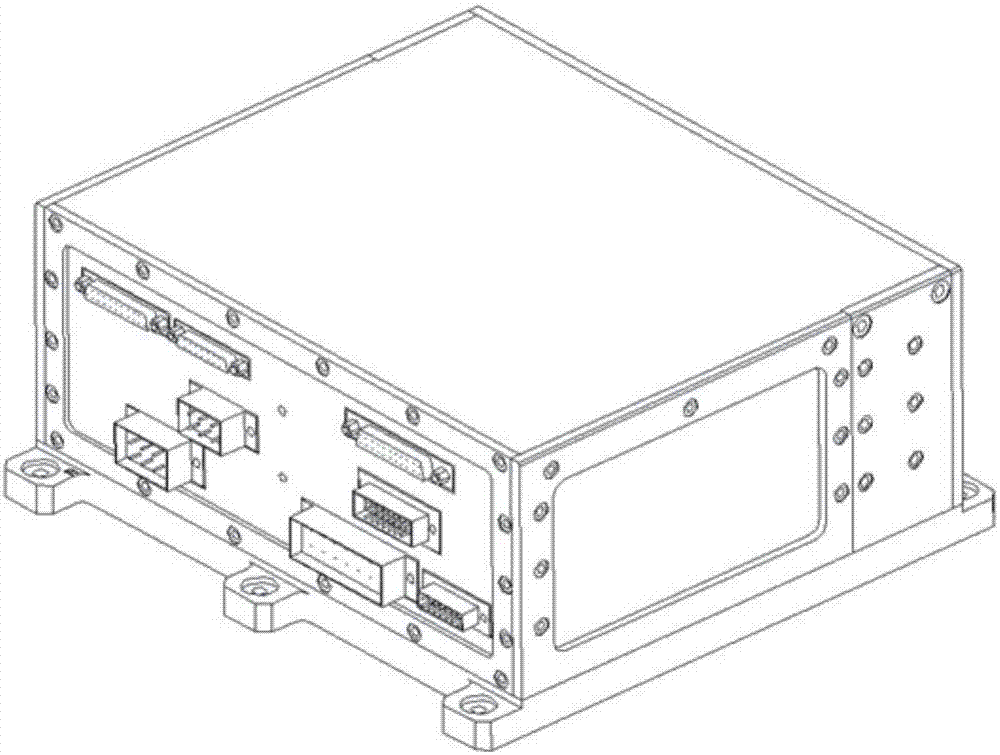

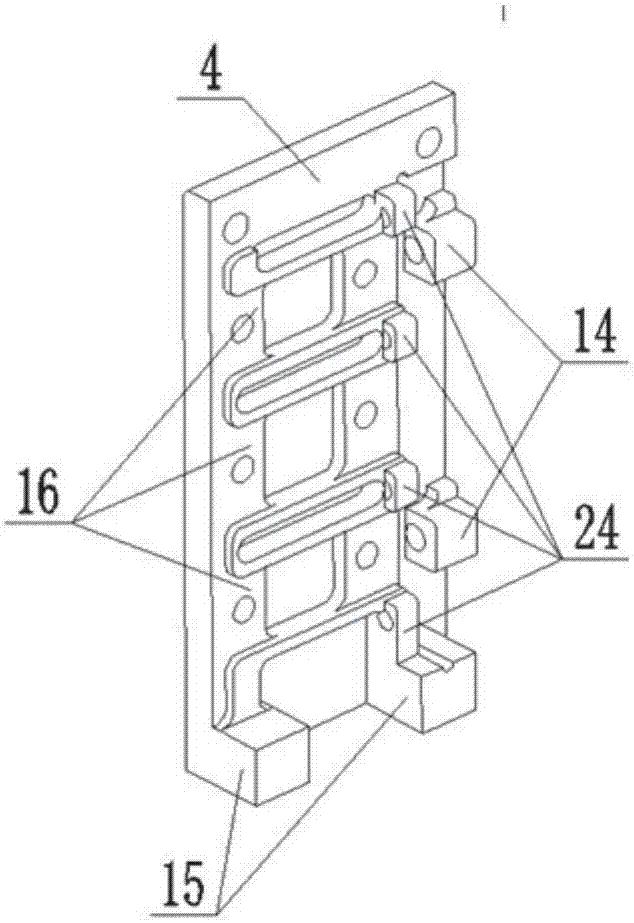

[0026] Such as figure 1 and figure 2 As shown, it is an exploded view and a complete machine view of a horizontal plug-in aerospace integrated electronic stand-alone structure provided by the present invention, respectively. The stand-alone structure is composed of a plurality of functional modules, a motherboard 2, a casing and auxiliary parts. The functional modules and the motherboard 2 are installed inside the casing, the functional modules are installed horizontally, and can be inserted and removed horizontally, and the motherboard 2 is installed vertically, and are in a vertical relationship with the functional modules . By inserting a plurality of functional modules laterally into the casing, the bus plug 22 on the functional printed board 1 of the functional modules is fitte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com