Method for preparing low-purine soybean protein food and prepared soybean protein food thereof

A soy protein, low purine technology, applied in the direction of bacteria, dairy products, milk replacers, etc. used in food preparation, can solve problems such as adverse reactions, poor stability, excessive protein denaturation, etc. Influence, the effect of reducing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

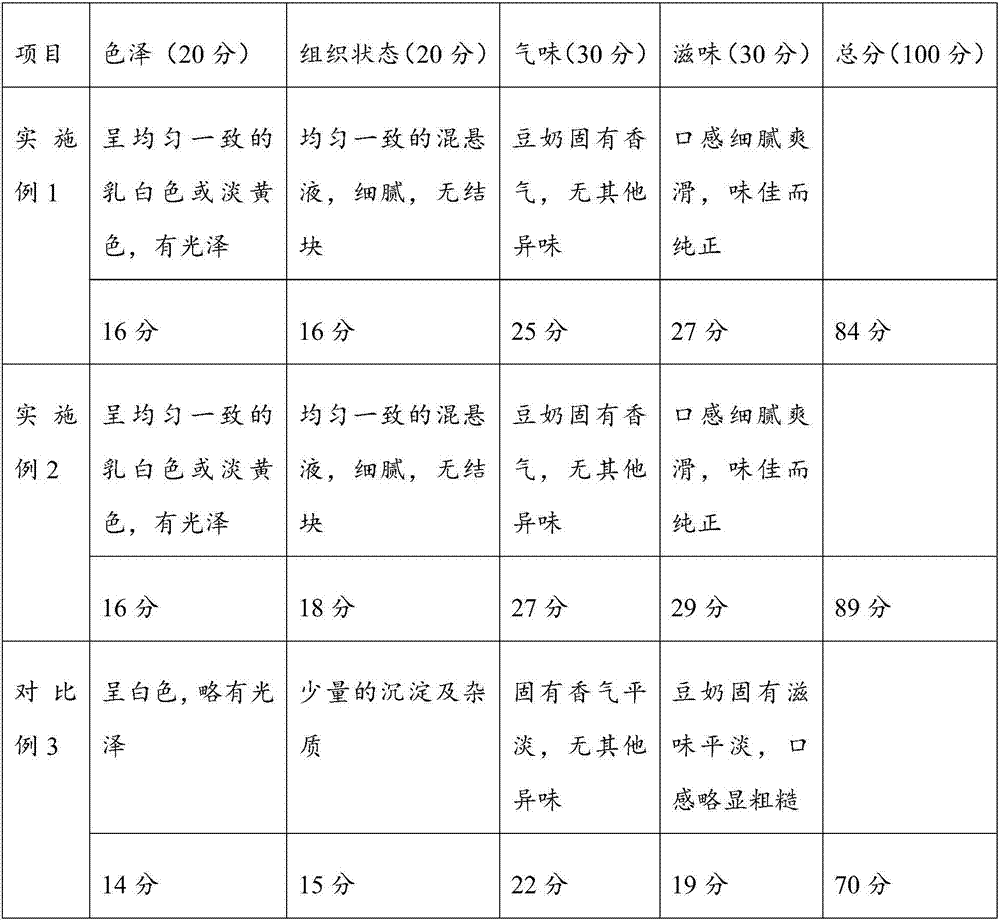

Embodiment 1

[0041] A method of using soybean meal to prepare soybean milk with low purine content, good protein stability, easy absorption and good taste, said method comprising the following steps:

[0042] (1) Put the solvent n-pentane and soybean embryo flakes into the leaching container at a ratio of 1:1.5 to the material and liquid, and degrease through simple tank group leaching, leaching times 3 times, leaching time 20min, leaching temperature 27°C, after leaching , release the mixed oil, and drain the soybean meal; the soybean meal enters the steamer for low-temperature vacuum precipitation, the precipitation time is 0.5h, the precipitation temperature is 40°C, and the vacuum degree is 75KPa, so as to obtain soybean meal with complete shape, white color and no peculiar smell.

[0043] (2) The soybean meal is subjected to instantaneous high-temperature sterilization. After the high-temperature sterilization treatment, the soybean meal is soaked in sterile water at 25°C, and the temper...

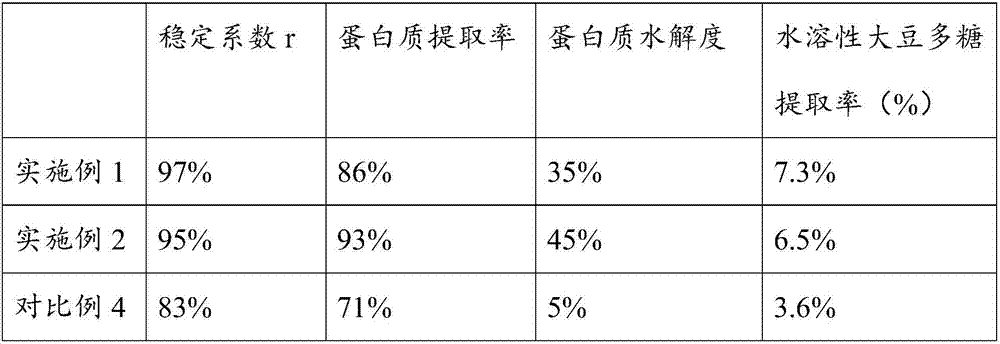

Embodiment 2

[0046] Refer to the method described in Example 1 to prepare soybean milk with low purine content, good protein stability, easy absorption and good taste. The only difference is:

[0047] After the hydrolysis reaction, the hydrolyzate and soybean meal are roughly separated, the separated soybean meal is refined, and then filtered to obtain soybean dregs and soybean milk; soybean peptide hydrolase, neutral protease and cellulase are added to the soybean milk for the second Secondary hydrolysis reaction, wherein, the dosage of soybean peptide hydrolase, neutral protease and cellulase is 4000U / g soybean meal, 2000U / g soybean meal and 200U / g soybean meal; the hydrolysis time is 1.5h; Heat at 80°C for 5 minutes to passivate the above-mentioned proteases; after hydrolysis, mix the first and second hydrolyzates, add only graphene oxide-modified zeolite to the mixture, adsorb for 2 hours, and then centrifuge to remove all The zeolite is prepared, and then processed and pasteurized to ...

Embodiment 3

[0049] Refer to the method described in Example 2 to prepare soybean milk with low purine content, good protein stability, easy absorption, good taste and rich nutrition, the only difference is:

[0050] In the method, after the first and second hydrolyzate are mixed, only zeolite modified by graphene oxide is added, adsorbed for 2h, then centrifuged to remove the zeolite, and then pasteurized; Bifidobacterium, Lactobacillus rhamnosus and Lactobacillus bulgaricus are added in the hydrolyzate of the hydrolyzate, after adding, the consumption of Bifidobacterium, Lactobacillus rhamnosus and Lactobacillus bulgaricus in the hydrolyzate is respectively 1.0×10-8 / mL, 2.0×10-8 pieces / mL, and 7.0×10-8 pieces / mL, the soy milk with low purine content, good protein stability, easy absorption, good taste and rich nutrition can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com