Reaction container capable of reducing reaction time of chemical raw materials

A reaction vessel and reaction time technology, applied in chemical/physical/physical-chemical stationary reactors, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of long reaction period and low industrial production efficiency, and achieve the The effect of heat dissipation, ensuring reaction temperature, and accelerating mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

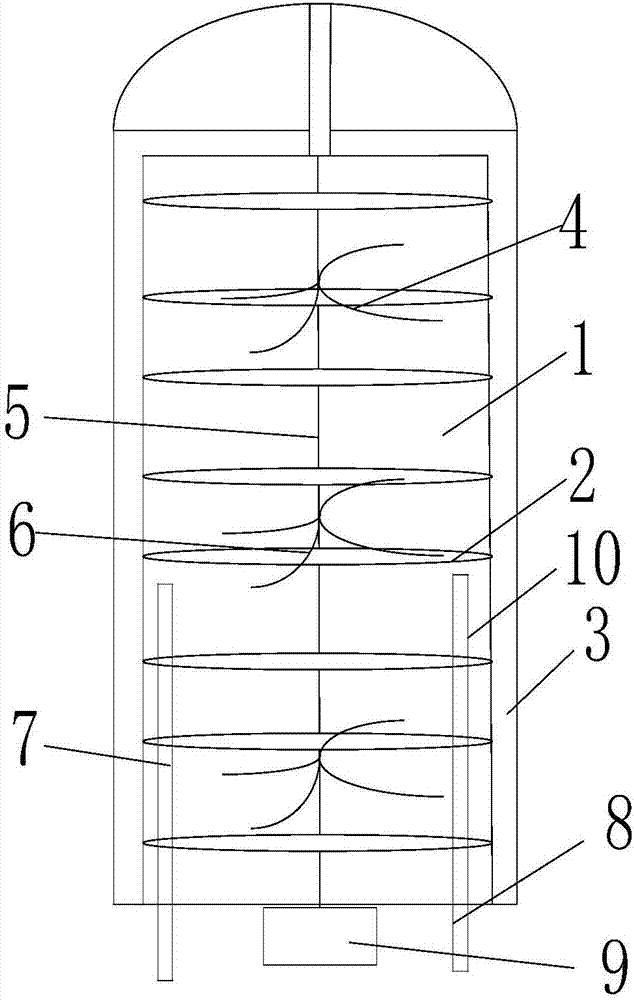

[0020] Such as figure 1 Shown, a kind of reaction container that shortens the reaction time of chemical raw materials, comprises reactor main body 1, and reactor main body 1 is hollow cylinder structure, is provided with reaction vessel 10 in reactor main body 1, and reaction vessel 10 and reactor main body 1 A vacuum cavity 3 is arranged between the inner walls, and a serpentine coil 2 is arranged inside the reaction vessel 10, and the serpentine coil 2 is arranged around the inner wall of the reaction vessel 10; the reaction vessel 10 is provided with a rotating shaft 5, and the rotating shaft The rotating blade group 4 is arranged on the 5, the lower end of the rotating shaft 5 is connected with the driving motor 9, and the driving motor 9 is connected with the frequency converter.

[0021] Reactor main body 1 described in the present embodiment is the main vessel that carries out raw material reaction, and the container of concrete realization is reaction vessel 10, and va...

Embodiment 2

[0025] The present embodiment is further defined on the basis of the embodiment. The bottom end of the reaction vessel 10 also has a first air inlet pipe 7 and a second air inlet pipe 8. The first air inlet pipe 7 and the second air inlet pipe 8 are connected from the reaction vessel 10 Insert at the bottom.

[0026] The function of the first inlet pipe 7 and the second inlet pipe 8 is to add gas such as air into the reaction vessel 10 to promote the boiling degree of the reaction raw materials in the reaction vessel 10 . Wherein, the first air intake pipe 7 and the second air intake pipe 8 are communication pipe structures. Other gas flow channels are also possible.

Embodiment 3

[0028] The difference between this embodiment and the above embodiments is that the distance between the position where the first air inlet pipe 7 is inserted into the reaction vessel 10 and the bottom of the reaction vessel 10 is 1 / 3-2 / 3 of the height of the reaction vessel 10 . The distance between the position where the second air inlet pipe 8 is inserted into the reaction vessel 10 and the bottom of the reaction vessel 10 is 1 / 5-2 / 5 of the height of the reaction vessel 10 .

[0029] Here, the first gas inlet pipe 7 and the second gas inlet pipe 8 are installed in the position of the reaction vessel 10, and the gas is passed through the first gas inlet pipe 7 and the second gas inlet pipe 8, and the gas is passed into different positions. The gas introduced can accelerate the boiling degree of the reaction raw materials in the reaction vessel 10. The specific structural shape of the reaction vessel 10 described in this embodiment is a hollow cylinder, and is located inside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com