Laser and electrolytic combined machining method and device

A compound processing and coupling device technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult processing of complex contours, large depth-to-diameter ratio fine structures, insufficient processing depth, large processing taper, etc., to achieve high Surface finish, good surface quality, low taper effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

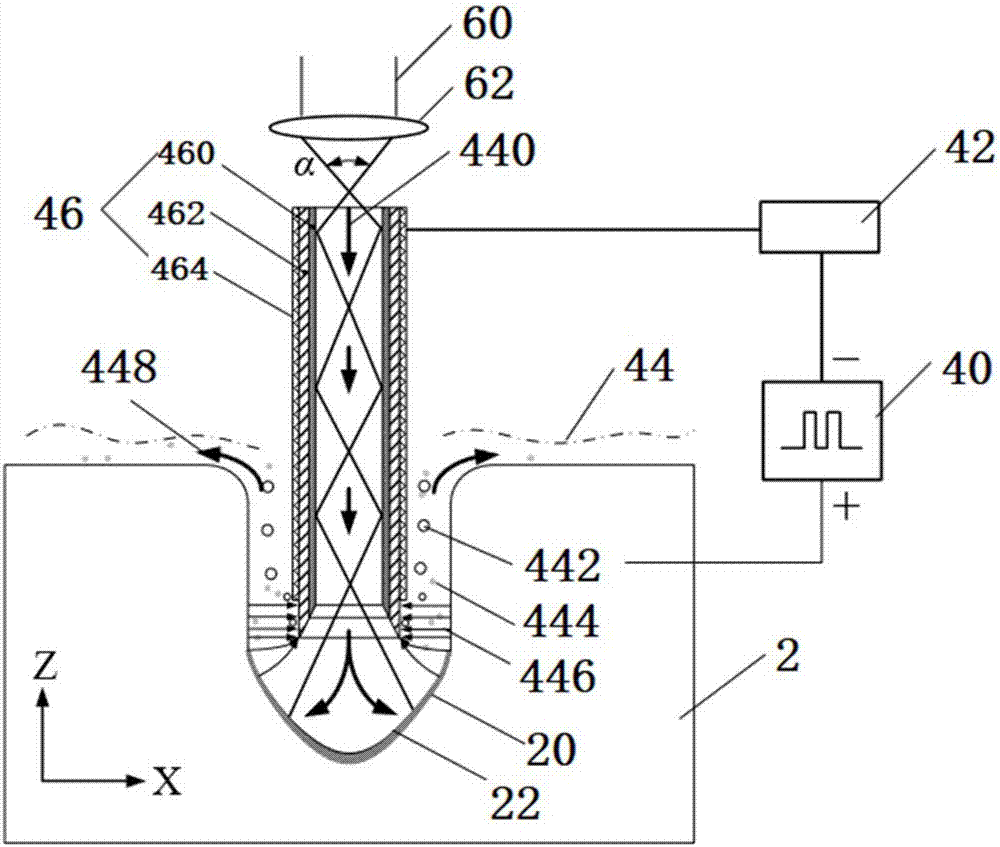

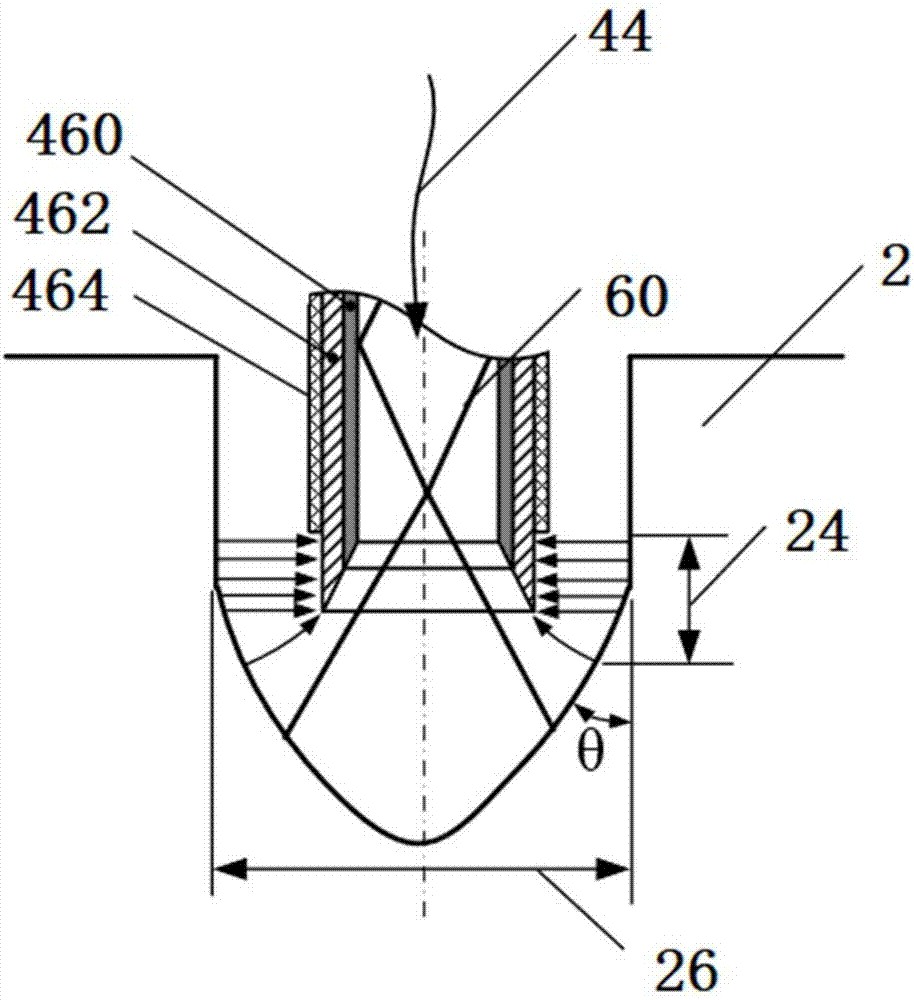

[0111] Embodiment 1 laser and electrolytic composite processing

[0112] In this embodiment, based on laser and electrolytic composite processing, the schematic diagrams involved are as follows figure 1 and figure 2 shown. Specifically include the following steps:

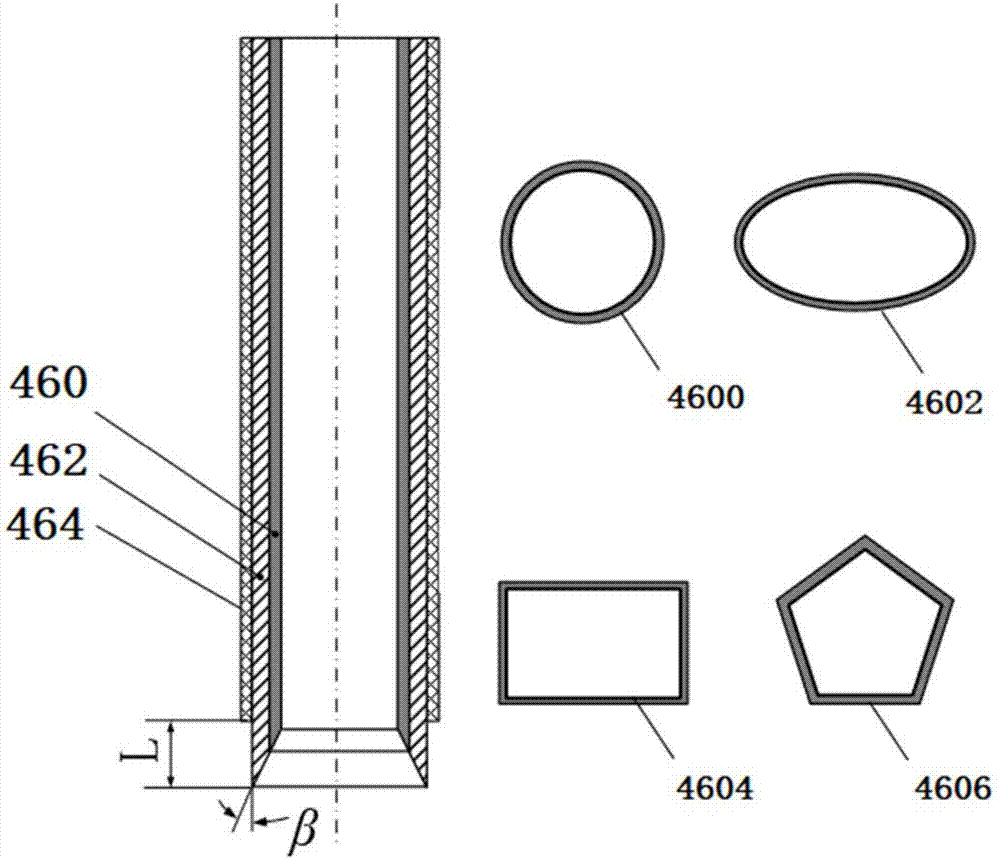

[0113] (1) The tool electrode 46 includes a metal conduit 462 and a liquid-core optical fiber 460 installed inside it, and the side of the metal conduit is coated with an insulating layer 464; the liquid-core optical fiber is coaxially located in the metal conduit.

[0114] Among them, the liquid core optical fiber is TEFLON AF2400 (DUPONT) purchased from BIOGENERAL company in the United States, and the optical refractive index is about n 1 = 1.29;

[0115] The metal conduit 462 is made of stainless steel, and its side is coated with an insulating layer by electrostatic spraying from top to bottom. The angle β between the inner wall and the outer wall is 30°.

[0116] (2) The electrolytic solution 44 flows f...

Embodiment 2

[0126] Example 2 Laser Interventional Micro Electrolytic Machining

[0127] The difference between the laser-intervened micro-electrolytic machining method in this embodiment and that in Embodiment 1 is:

[0128] The metal conduit 462 is made of stainless steel, and its side is coated with an insulating layer by electrostatic spraying from top to bottom. The angle β between the inner wall and the outer wall is 70°.

[0129] The interfaces of the liquid-core optical fiber, the tool electrode and the metal conduit are rectangular.

[0130] Wherein, the tool electrode 46 is clamped above the workpiece 2, and the initial machining gap between the end of the tool electrode and the workpiece processing surface is set to be about 1 mm; the feed speed of the tool electrode is 100 μm / s.

[0131] The energy density of the laser beam 60 acting on the processed surface of the workpiece 2 is 1.5-5GW / cm 2 ;The flow rate of electrolyte is 0.1~0.5m 3 / h.

[0132] The pore structure is ob...

Embodiment 3

[0133] Example 3 Laser Interventional Micro Electrolytic Machining

[0134] The difference between the laser-intervened micro-electrolytic machining method in this embodiment and that in Embodiment 1 is:

[0135] The liquid-core optical fiber is a TEFLON AF capillary purchased from BIOGENERAL.

[0136] The metal conduit 462 is made of stainless steel, and its side is coated with an insulating layer by electrostatic spraying from top to bottom. The angle β between the inner wall and the outer wall is 45°.

[0137] The interfaces of the liquid-core optical fiber, the tool electrode and the metal conduit are rectangular.

[0138] Wherein, the tool electrode 46 is clamped above the workpiece 2, and the initial machining gap between the end of the tool electrode and the workpiece processing surface is set to be about 0.5 mm; the feed speed of the tool electrode is 50 μm / s.

[0139] The energy density of the laser beam 60 acting on the processed surface of the workpiece 2 is 5-10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com