Vibrating wire sensor excitation optimization method and vibrating wire acquisition device

A technology of vibrating wire sensor and optimization method, which is applied in the direction of measuring device, measurement of force by measuring the frequency change of the stressed vibrating element, instruments, etc., which can solve the problem that the measurement accuracy of the vibrating wire sensor is easily disturbed by the ambient temperature, and the acquisition device Does not support long-distance data transmission, metal string vibration duration is short, etc., to achieve the effect of shortening the start-up time and detection time, enhancing anti-interference ability, and prolonging the vibration duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

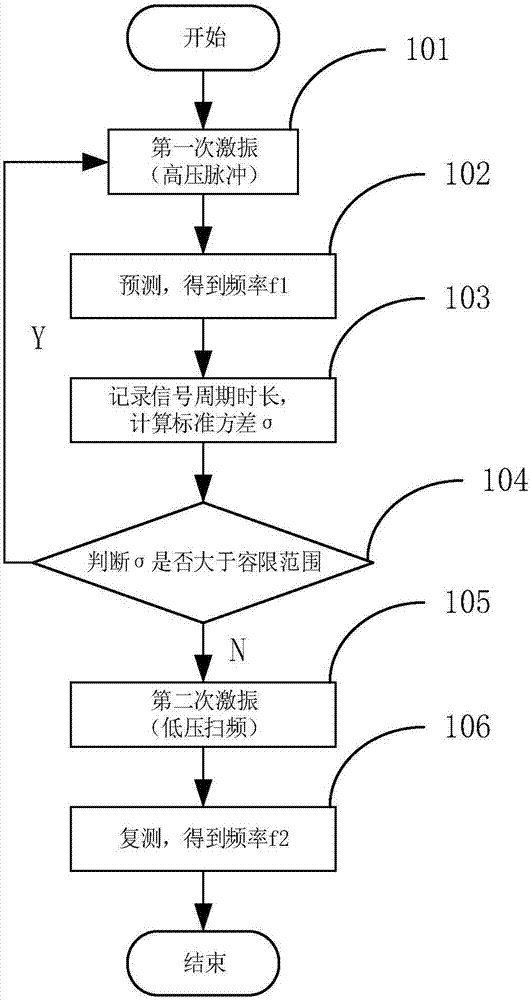

[0035] Such as figure 1 As shown, the vibrating wire sensor excitation optimization method of the present invention includes the following steps:

[0036] Step 101: Excitation for the first time: Excite the selected vibrating wire sensor once by means of high-voltage pulse excitation.

[0037] Step 102: Prediction: amplify and filter the collected signal of the vibrating wire measured by the vibrating wire sensor, and measure its signal frequency to obtain the resonant frequency f1 of the vibrating wire. Since the high-voltage pulse excitation method has the disadvantages of short duration of metal string vibration, difficult signal pickup, and poor measurement accuracy, the frequency f1 obtained by the high-voltage pulse excitation method is only a rough value close to the exact resonance frequency. If you want to improve Its frequency measurement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com