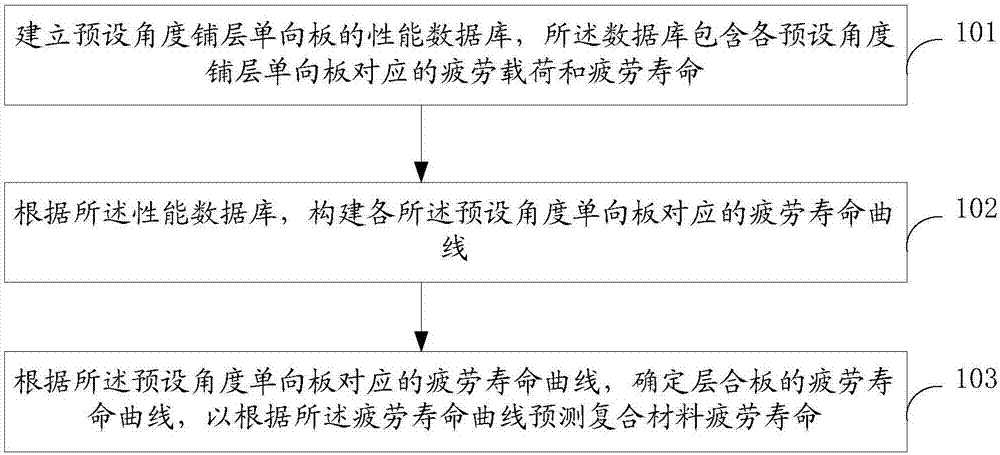

Fatigue life prediction method of composite material, apparatus and electronic equipment thereof

A technology of fatigue life prediction and fatigue life, which is applied in the direction of measuring devices, analysis materials, instruments, etc., can solve the problems that materials cannot be fully utilized in the prediction period, prediction is too conservative, and the cost is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

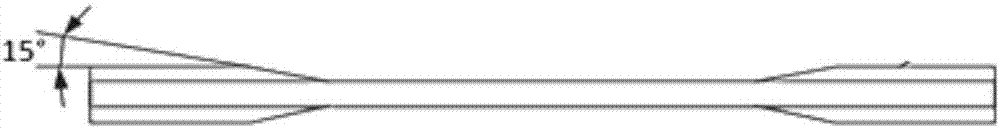

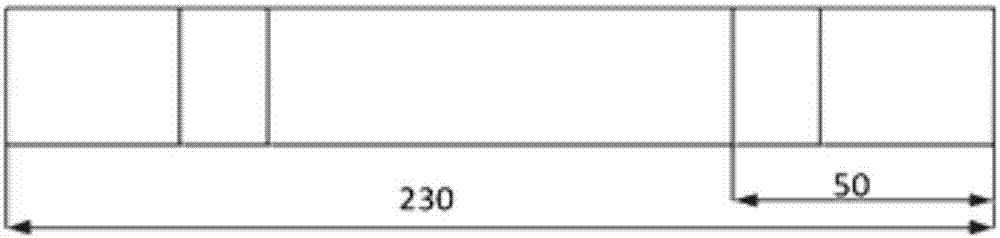

[0157] a) Tensile test pieces and compression test pieces for static tests and uniaxial fatigue tests of 0°, 45°, 90° laminated unidirectional plates made of composite material, the composite material is resin matrix with epoxy resin , with carbon fiber as reinforcement, the structure of the tensile test piece is as follows Figure 2a with 2b As shown, the structure of the compression test piece is as follows Figure 3a with 3b As shown, the two test pieces both include aluminum clamping pieces and composite material main structure, where the width of the tensile test piece and the compression test piece are both 25mm, the length of the tensile test piece is 230mm, and the length of the compression test piece is 135mm, the length of the holding piece of the tensile test piece is 50mm, the length of the holding piece of the compression test piece is 55mm, and the holding piece of the tensile test piece has a 15° inclination transition, and the thickness of the holding piece i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com