Damage-free quick measurement method of high temperature contact thermal resistance

A technology of contact thermal resistance and measurement method, applied in the field of ultrasonic testing, can solve the problems that the measurement process is easily affected by various factors, the measurement accuracy is difficult to guarantee, and the formula derivation is complicated, etc., and achieves fast measurement speed, short measurement period, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

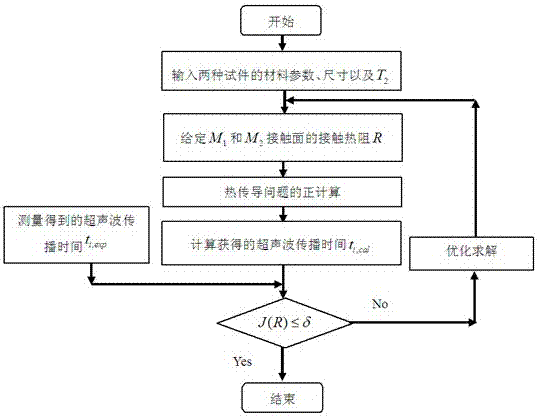

[0026] Carry out the implementation of specific case according to technical scheme of the present invention and step, as follows:

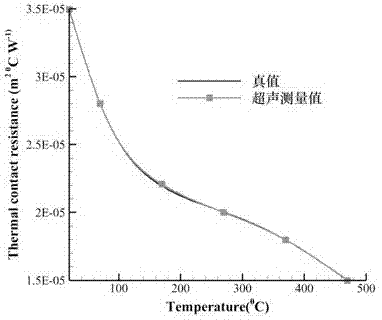

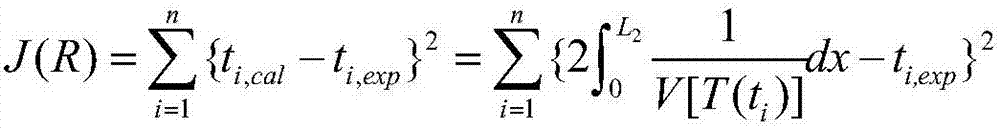

[0027] m 1 One end of the tested piece is subjected to a flat heater T=550°C, and the rest of the surface is an insulating surface. The ultrasonic probe is placed at M 2 The upper end surface of the tested piece is excited with pulsed ultrasonic waves in the vertical incidence mode, based on the measurement of M 2 The change of echo propagation time in the test piece, by solving the thermal / acoustic coupling inverse problem, the inverse M 1 Test piece and M 2 The thermal contact resistance at the interface of the specimen.

[0028] Case1M 1 Test piece and M 2 The contact thermal resistance R of the specimen interface does not change with temperature, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com