Capacitance mask resistance sensor

A resistance sensor, shielding technology, applied in inductors, measuring current/voltage, instruments, etc., can solve problems such as endangering system safety, easily causing ferromagnetic resonance, and large maintenance workload, achieving high safety and reliability, overcoming Ferromagnetic resonance, less maintenance work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

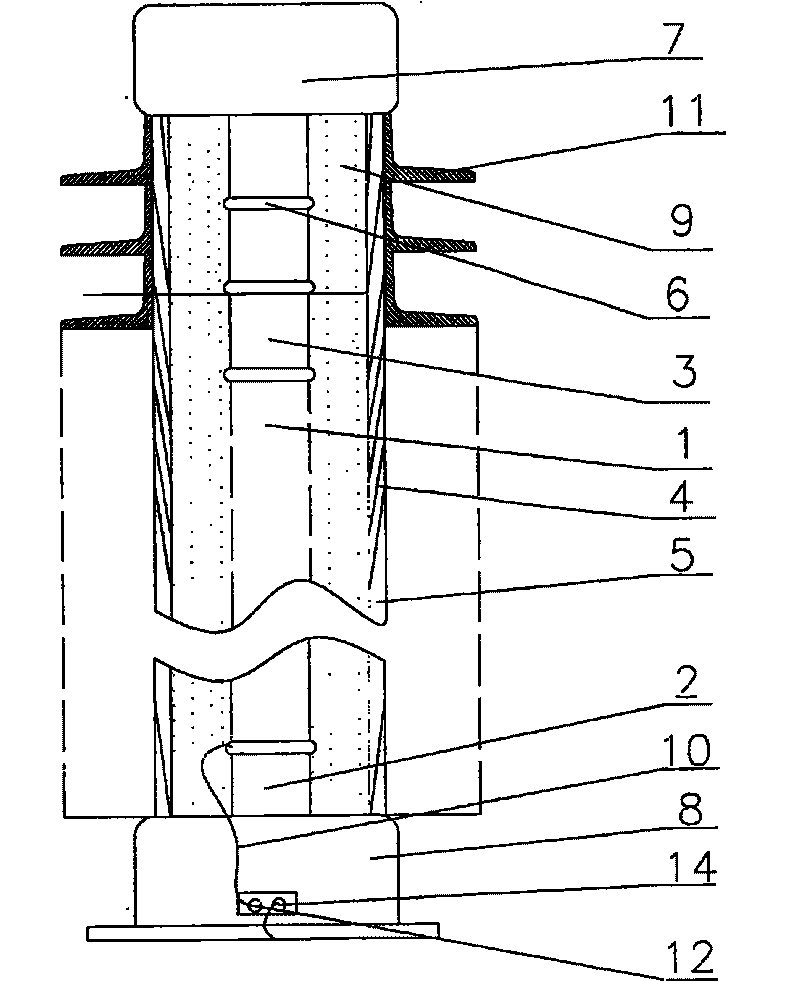

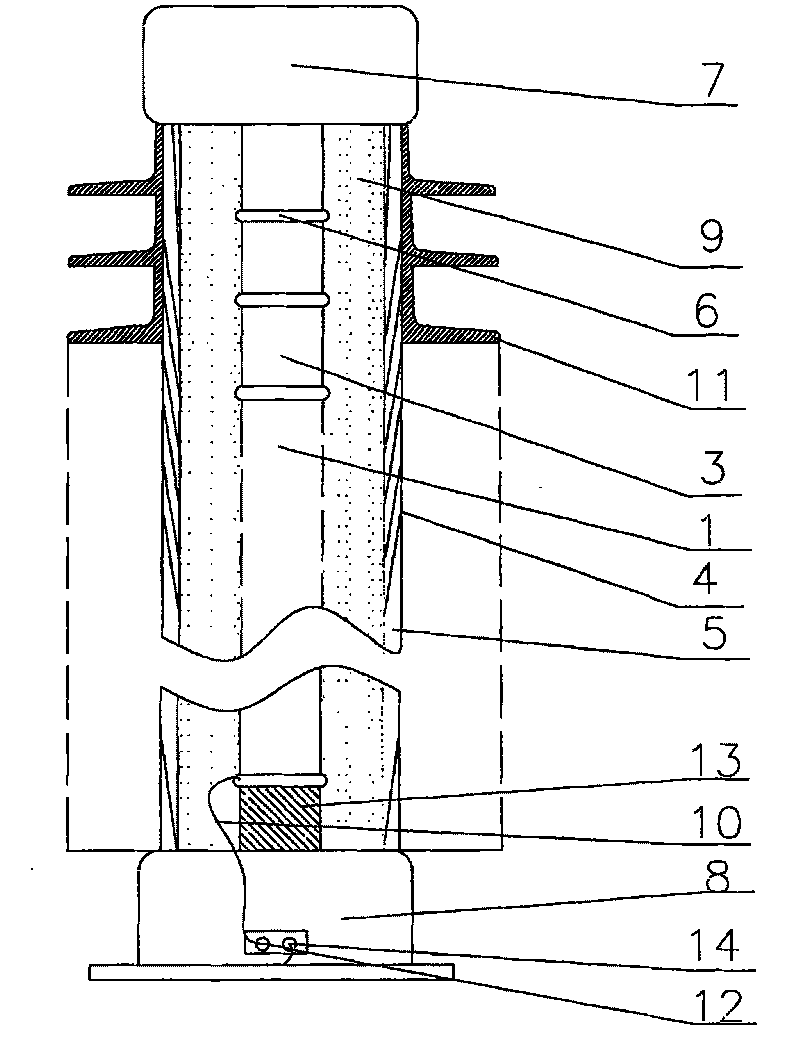

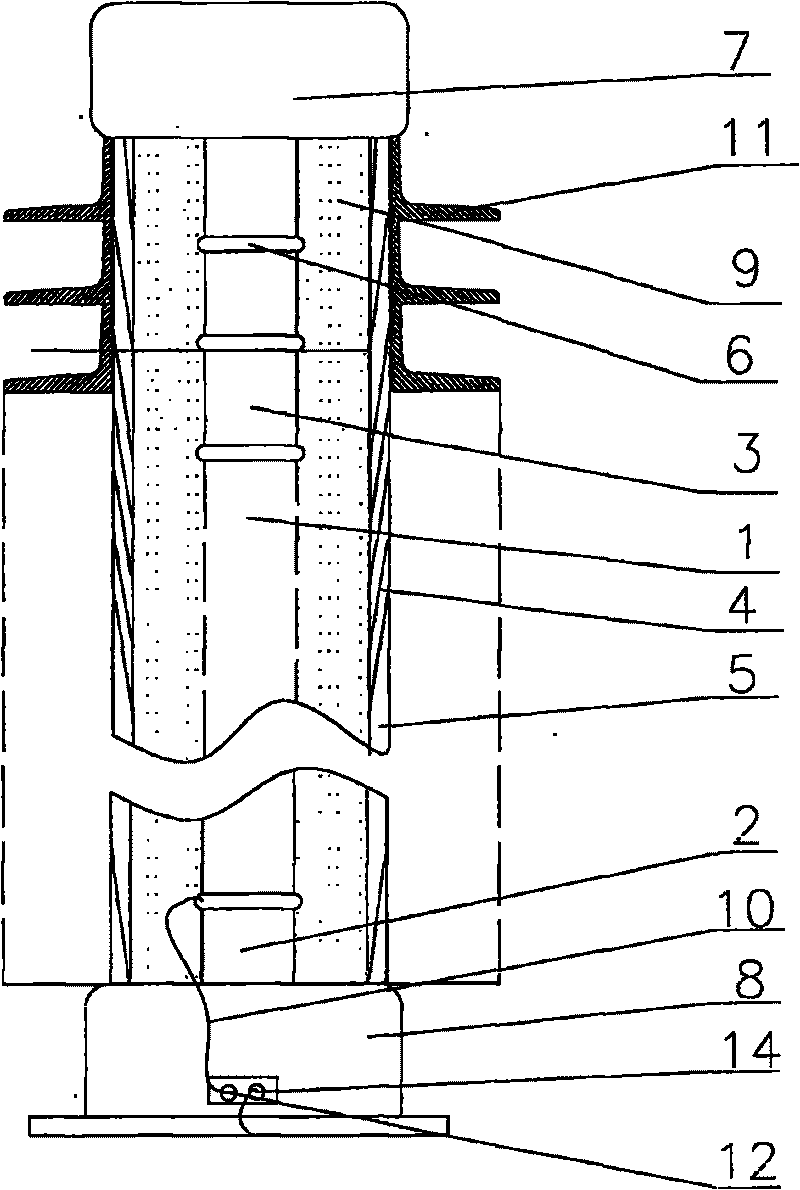

[0021] see figure 1 , which shows a first embodiment of the capacitive shielded resistance sensor of the present invention, (for example, a 110 kV capacitive shielded resistance sensor). It includes a high-voltage resistance column 1 (for example, a total resistance of 200MΩ), low-voltage resistor 2 (for example, 20kΩ wire resistance), pressure equalizing cover 7 (for example, aluminum hemispherical pressure equalizing cover), base 8 (for example, stainless steel base), silicone rubber shed 11, The measuring leads 10 and the measuring terminals 12 are composed of several cylindrical metal screens or semi-conductive screens 4 (for example, 20 aluminum foil screens) that are nested and isolated from each other and are concentric with the high-voltage resistance column 1, from top to bottom in the axial direction. The bottom is fixed in the insulating medium in turn to form a cylindrical capacitive shielding layer 5 (for example, glass filaments impregnated with epoxy resin are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com