Discarded type sleeve cutterhead

It is a technology of discarding and set cutters, which is applied in the direction of milling cutters, manufacturing tools, metal processing equipment, etc., and can solve problems such as high production costs, unstable blanks, and poor outer surface finish.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

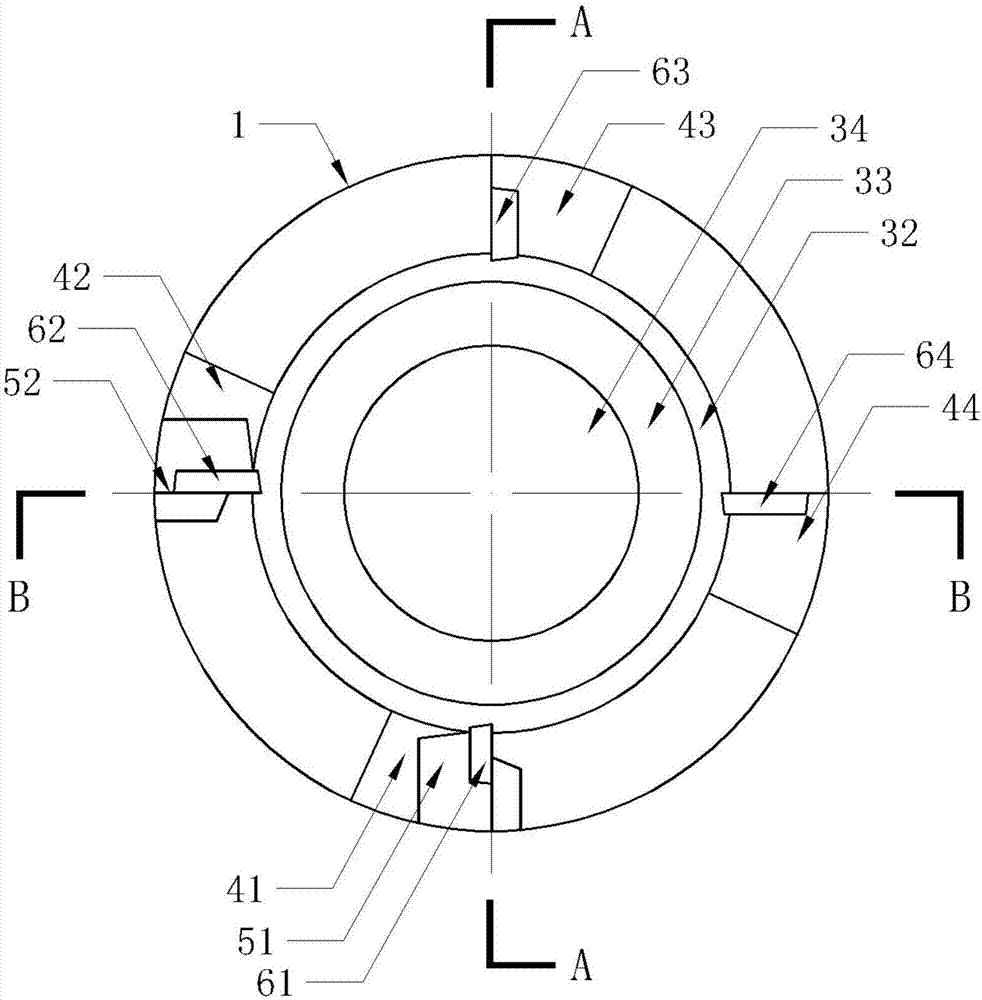

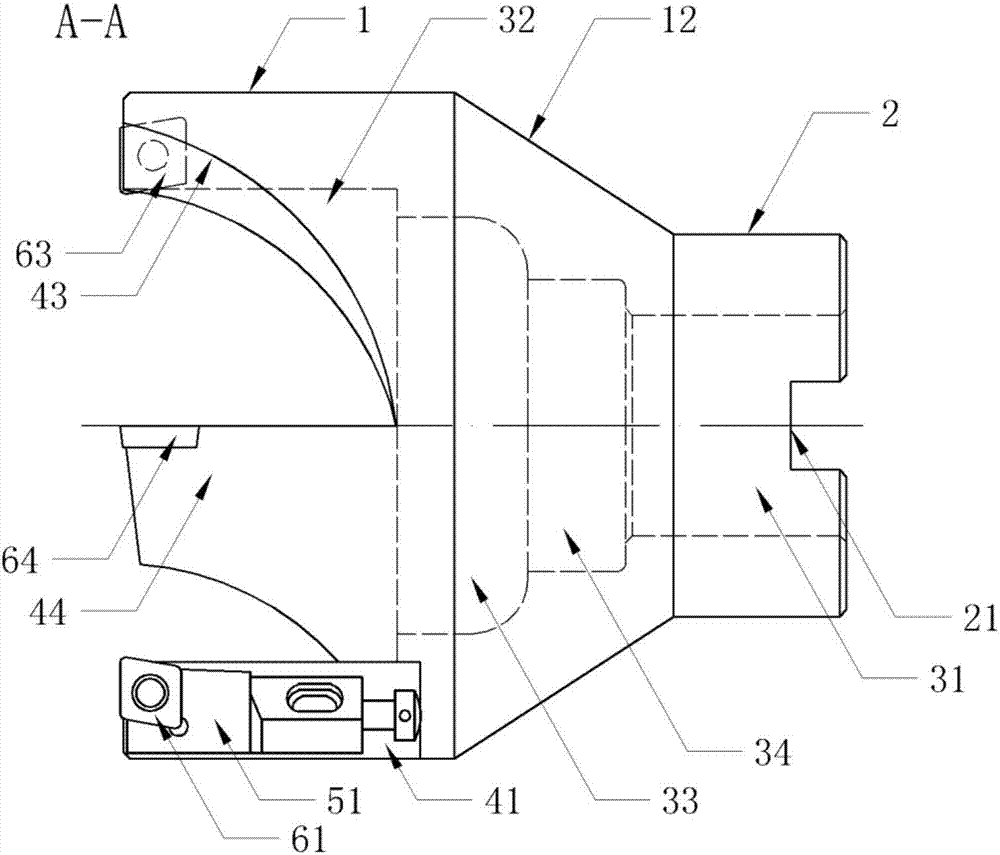

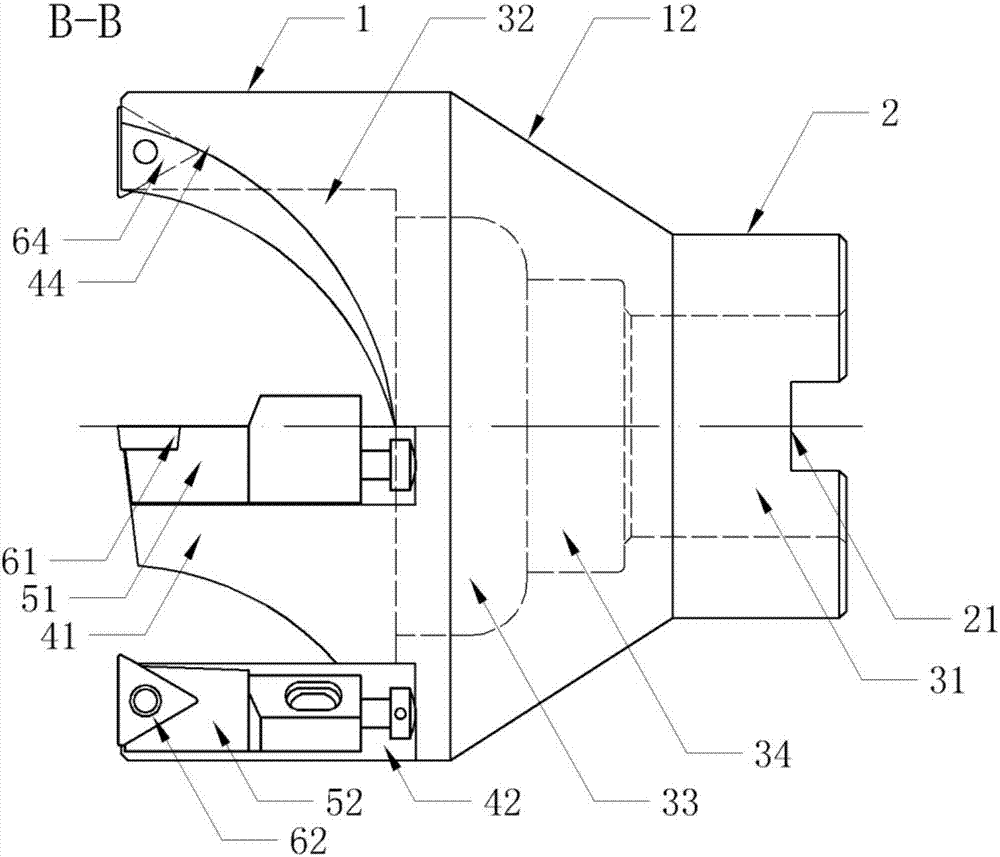

[0014] Such as Figure 1 to Figure 3 As shown, the present invention proposes a discarded cutter set, including a cutter head 1, a knife handle 2, two tool holders and four blades.

[0015] Specifically, a transitional hypotenuse 12 is provided between the cutter head 1 and the knife handle 2; the end surface of the knife handle 2 is provided with a first hole 31 for installing a milling cutter handle, and the end surface of the knife handle 2 is provided with Groove 21 installed in cooperation with the milling tool shank; the end surface of the cutter head 1 is provided with a second hole 32 for receiving chips, and chip removal is performed while processing, and the bottom end of the second hole 32 is provided with There is a third hole 33 to avoid the interference of parts, which reduces the interference to parts and improves the machining accuracy; further, in this embodiment, the preferred solution is: the cutter head 1 and the knife handle 2 are integrally structured, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com